nife-ldh@cos x /nf composite material and its preparation method and application

A composite material and reaction mixture technology, applied in electrolysis components, electrodes, electrolysis process, etc., can solve the problems of high price of water splitting reaction catalysts, only have HER or OER catalytic activity, etc., to increase catalytic active sites, excellent OER and HER performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The first aspect of the present application provides a NiFe-LDH@CoS x The preparation method of / NF composite material, it comprises the steps:

[0035] (1) adding iron source and urea to deionized water, stirring to obtain the first reaction mixture;

[0036] Wherein, the molar ratio of the iron source to the urea is 1: (3-7), and the molar ratio of the iron source to the deionized water is 1: (16-20) mol / L;

[0037] (2) hydrothermally reacting the first reaction mixture with nickel foam (NF) at 80-120°C for 6-10 hours, after the reaction is completed, wash with distilled water and absolute ethanol, and dry to obtain NiFe-LDH / NF composite materials;

[0038] (3) dissolving the cobalt source and the sulfur source in deionized water to obtain a second reaction mixture;

[0039] Wherein, the molar ratio of the cobalt source to the sulfur source is 1: (90-110), and the molar ratio of the sulfur source to the deionized water is (0.5-3.5): 1mol / L;

[0040] (4) Immerse the...

Embodiment 1

[0057]

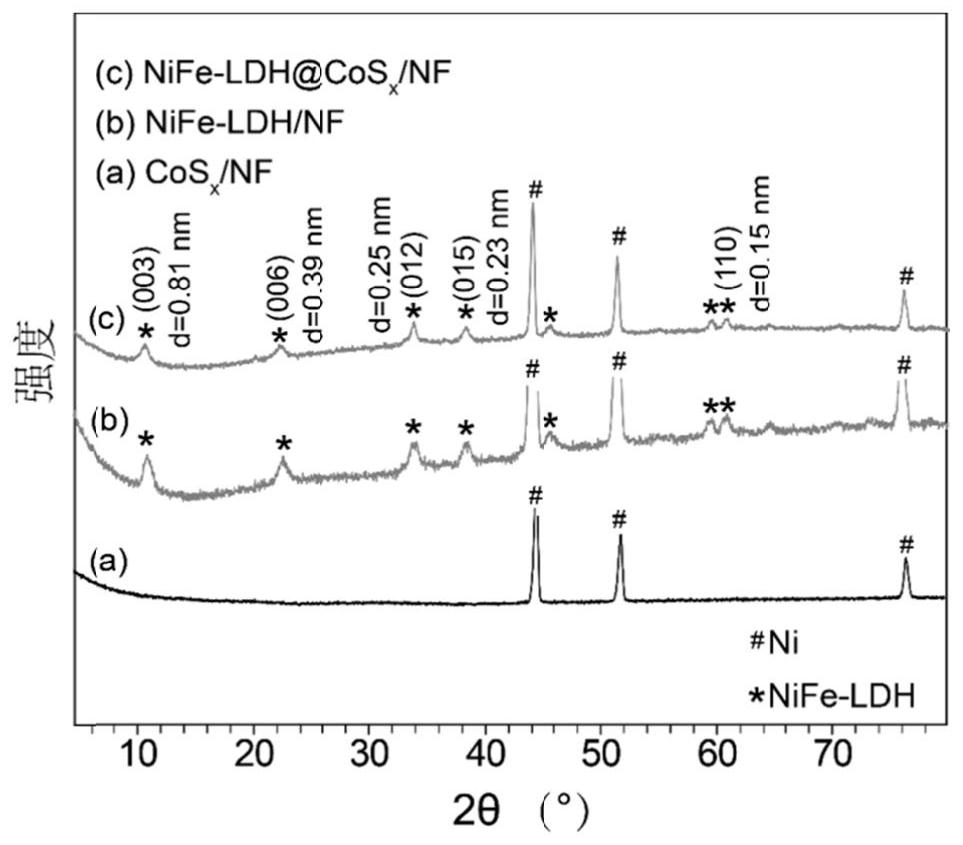

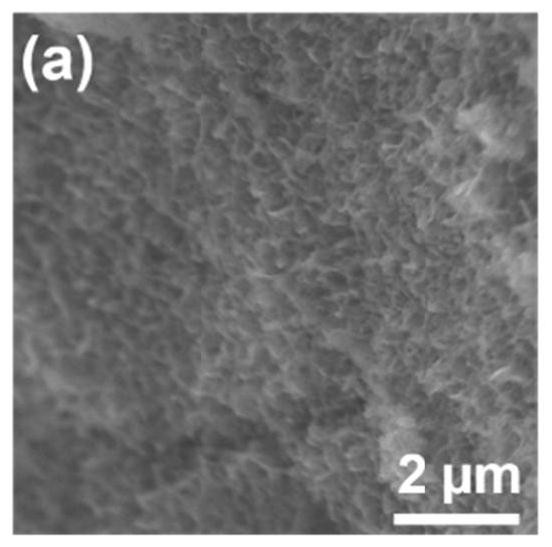

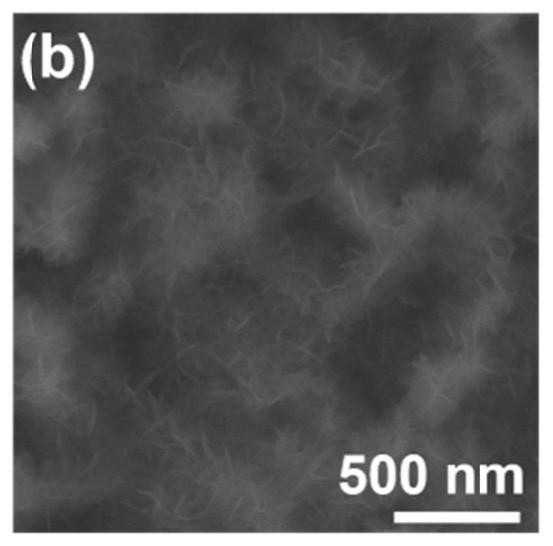

[0058] Weigh 0.808g (2mmol) iron nitrate (Fe(NO 3 ) 3 9H 2 O), 0.601g (10mmol) urea was stirred in 36ml deionized water to form a transparent and uniform yellow solution. The solution and the pretreated NF (2cm×3cm) were transferred to a stainless steel autoclave with a polytetrafluoroethylene liner of 50ml, sealed, and reacted in an oven at 100°C for 8h. After the reaction was completed, it was washed with distilled water and absolute ethanol, and dried to obtain NiFe-LDH / NF grown on NF.

[0059] The pretreatment process of NF is as follows: cutting NF into 2cm×3cm sheets, soaking in 5% hydrochloric acid solution for 20-30min, and then ultrasonically cleaning with acetone, deionized water and ethanol for 10-15min respectively.

[0060]

[0061] Weigh 0.58g (2mmol) cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 15.2g (200mmol) thiourea, be dissolved in 100ml deionized water, form the Co that concentration is 20mmol / L 2+ solution.

[0062] After cutting the prepared...

Embodiment 2

[0064] Except that iron source is ferric chloride, all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com