Hollow mesoporous copper/titanium dioxide/nickel catalyst for desulfurization as well as preparation and application thereof

A titanium dioxide and nickel catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem that the alumina carrier is difficult to meet the requirements, has poor stability, and hinders the application. and other problems, to achieve the effect of outstanding desulfurization effect, beneficial to industrial production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

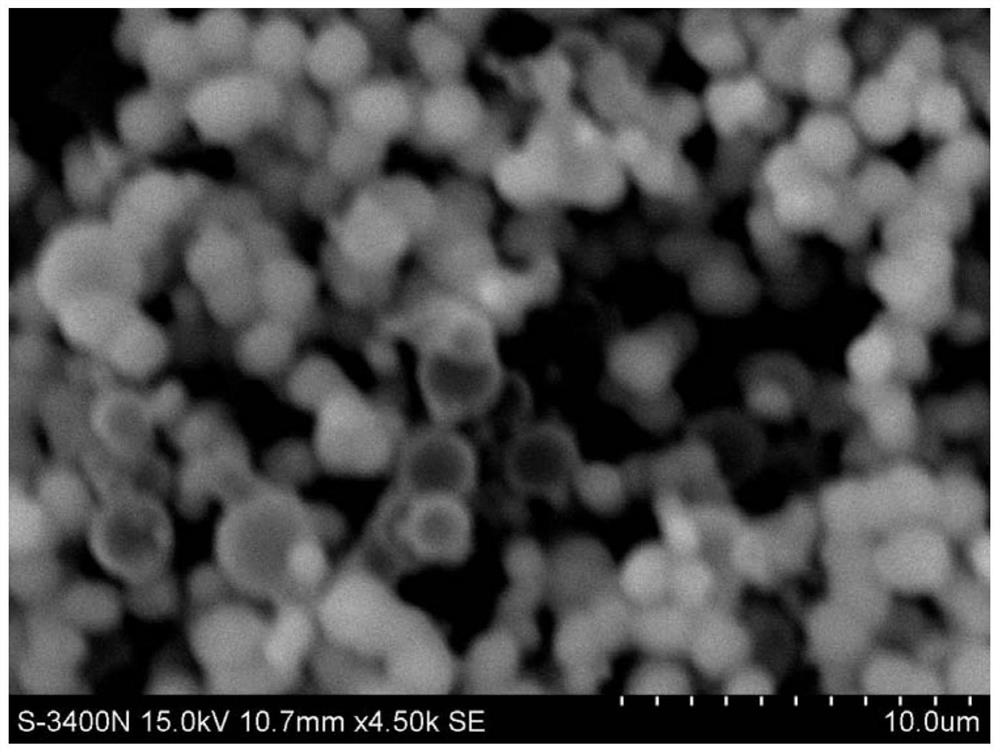

[0040] A hollow mesoporous copper / titanium dioxide / nickel core-shell catalyst for desulfurization is prepared by the following method:

[0041] Measure 4mL tetraethyl orthosilicate (TEOS) and 140mL absolute ethanol, stir evenly with a magnetic force, mark it as solution A, and set aside; measure 4mL ammonia water and 25mL H 2 O, magnetically stir evenly, mark it as solution B, and wait for use; use a constant flow pump, slowly drop solution B into solution A at a flow rate of 2mL / min, stir vigorously at 25°C for 24h, and the stirring speed is 1100rpm; The resulting liquid was centrifuged and washed three times with deionized water and absolute ethanol respectively, and measured with a pH meter until it was neutralized, and the obtained solid was dried overnight at 110° C. in a drying oven. Finally, the dried solid was calcined in a tube furnace at a heating rate of 2 °C / min at 550 °C for 5 h to obtain spherical SiO 2 nanoparticles;

[0042] 0.2g SiO 2 Nanoparticles were dis...

Embodiment 2

[0046] A hollow mesoporous copper / titanium dioxide / nickel core-shell catalyst for desulfurization is prepared by the following method:

[0047] Measure 4mL tetraethyl orthosilicate (TEOS) and 140mL absolute ethanol, stir evenly with a magnetic force, mark it as solution A, and set aside; measure 4mL ammonia water and 25mL H 2 O, magnetically stir evenly, mark it as solution B, and wait for use; use a constant flow pump, slowly drop solution B into solution A at a flow rate of 2mL / min, stir vigorously at 25°C for 24h, and the stirring speed is 1100rpm; The resulting liquid was centrifuged and washed three times with deionized water and absolute ethanol respectively, and measured with a pH meter until it was neutralized, and the obtained solid was dried overnight at 110° C. in a drying oven. Finally, the dried solid was calcined in a tube furnace at a heating rate of 2 °C / min at 550 °C for 5 h to obtain spherical SiO 2 nanoparticles;

[0048] 0.2g SiO 2 Nanoparticles were dis...

Embodiment 3

[0052] A hollow mesoporous copper / titanium dioxide / nickel core-shell catalyst for desulfurization is prepared by the following method:

[0053] Measure 4mL of tetraethyl orthosilicate (TEOS) and 140mL of absolute ethanol, stir evenly with a magnetic force, mark it as solution A, and set aside; measure 4mL of ammonia water and 25mL of H 2 O, magnetically stir evenly, mark it as solution B, and wait for use; use a constant flow pump, slowly drop solution B into solution A at a flow rate of 2mL / min, stir vigorously at 25°C for 24h, and the stirring speed is 1100rpm; The resulting liquid was centrifuged and washed three times with deionized water and absolute ethanol respectively, and measured with a pH meter until it was neutralized, and the obtained solid was dried overnight at 110° C. in a drying oven. Finally, the dried solid was calcined in a tube furnace at a heating rate of 2 °C / min at 550 °C for 5 h to obtain spherical SiO 2 nanoparticles;

[0054] 0.2g SiO 2 Nanopartic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com