Fine regulation supported alloy catalyst and preparation method and application thereof

An alloy catalyst and a supported technology are applied in the field of finely regulated supported alloy catalysts and their preparation, which can solve problems such as low activity and achieve the effects of easy availability of raw materials, reduced material cost, and 100% hydrogen production selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

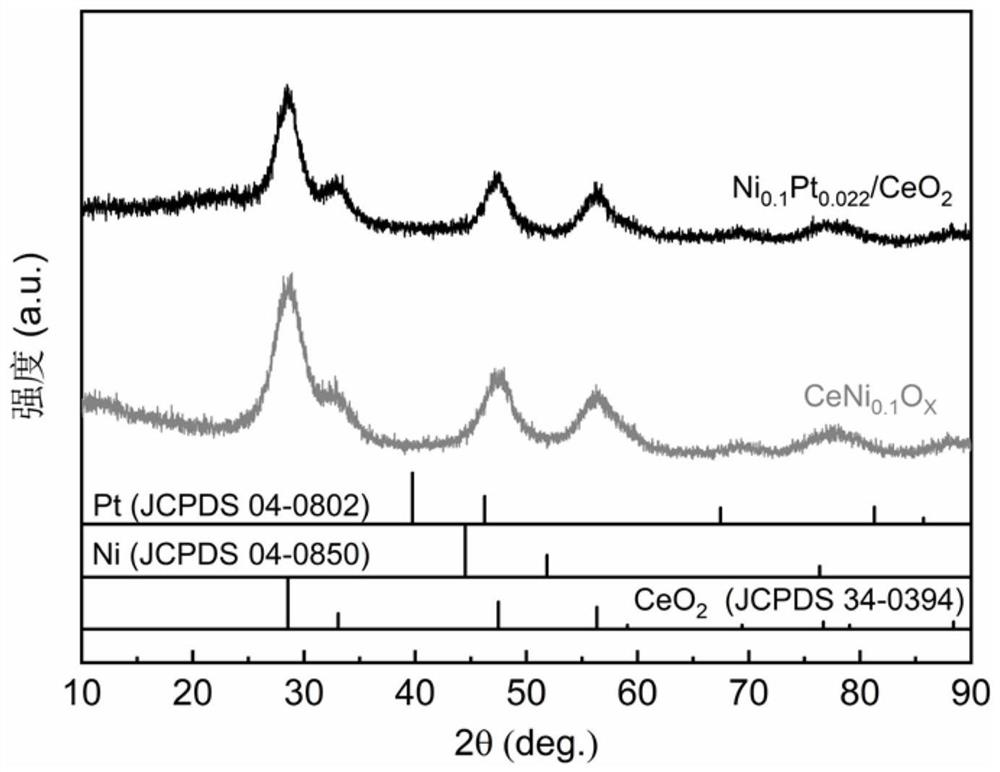

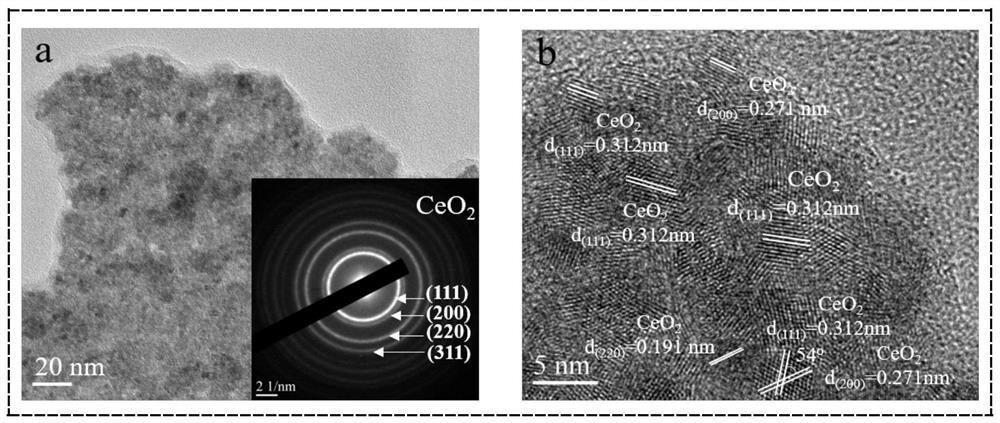

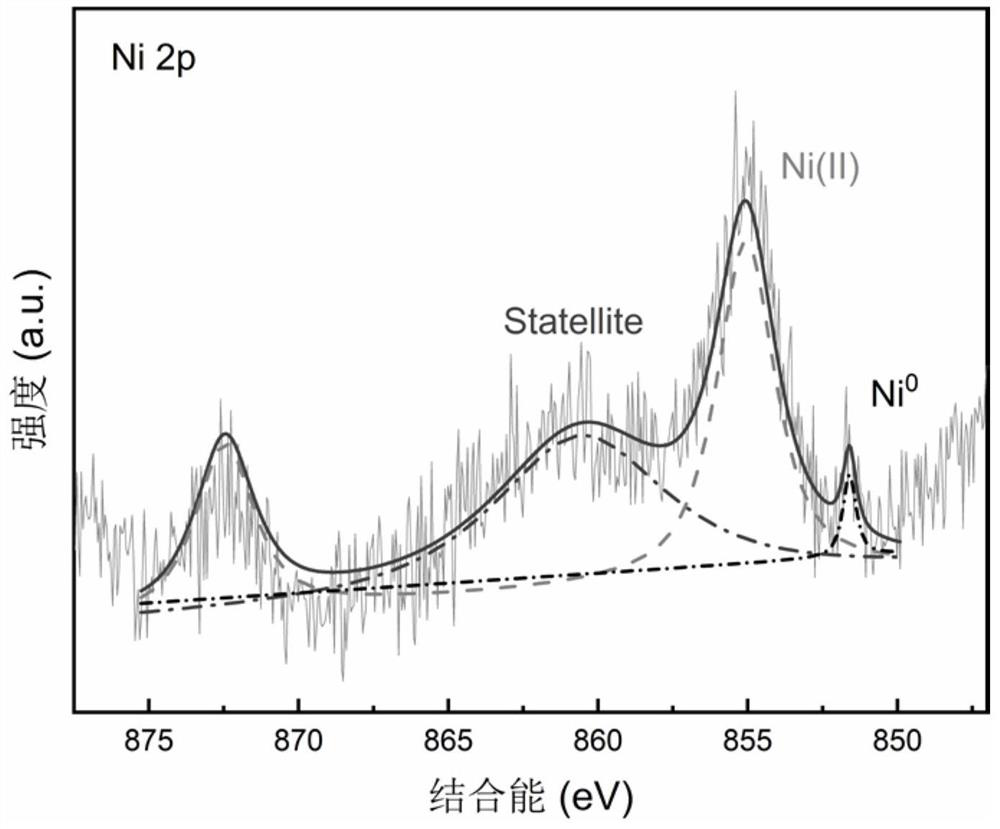

[0057] The preparation of the catalyst can be divided into three steps of hydrothermal-electrostatic adsorption-reduction heat treatment. The first step: 2mmol of Ce(NO 3 ) 3 ·6H 2 O and 0.2mmol Ni(NO 3 ) 2 ·6H 2 O was completely dissolved in 20ml of ethanol solution, stirred in a constant temperature water bath at 60°C, another 6.5mmol of tetramethylammonium hydroxide (TMAH) was completely dissolved in 5mL of ethanol solution, and then added dropwise to the metal precursor salt solution, The reaction was stirred at 60°C for 2h. Then the reaction solution was transferred to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, and aged at a constant temperature of 80° C. for 12 h. Then, the solid solution CeNi can be obtained by centrifugal washing and drying. 0.1 o x ; Second step: use hydrochloric acid or sodium hydroxide solution to H 2 PtCl 6 or [Pt(NH 3 ) 4 ] Cl 2 The initial pH value of the solution (1mM) was adjusted to about 3.5 (the final pH val...

Embodiment 2

[0066] (1) Preparation of catalyst:

[0067] In order to further explore the universality of the above method, try to change the solute metal and noble metal in the solid solution, the specific metal used and the content are: Co(NO 3 ) 2 ·6H 2 O (0.2mmol), H 2 IrCl 6 ·6H 2 O (0.044mmol), preparation condition is the same as embodiment 1, can obtain target catalyst sample Co 0.10 Ir 0.022 / CeO 2 , the prepared catalyst samples were stored in a glove box filled with an Ar atmosphere to minimize oxidation.

[0068] (2) Phase and structural characterization of the catalyst:

[0069] Figure 8 For this embodiment in the obtained target catalyst Co 0.10 Ir 0.022 / CeO 2 and its precursor CeCo 0.10 o x X-ray diffraction pattern of . Both samples were found to exhibit CeO by XRD characterization 2 phases, but no Ni, Ir, or Ni-Ir alloy phases were observed, indicating that the catalyst particles prepared by this method were extremely small in size or in an amorphous phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com