Steel ladle anti-erosion aggregate preparation process and equipment thereof

An anti-erosion and aggregate technology, applied in the field of aggregate, can solve the problems of large equipment investment, high wear and power consumption, and difficult to control, so as to increase the contact area, improve the degree of sealing, and reduce the possibility of seepage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

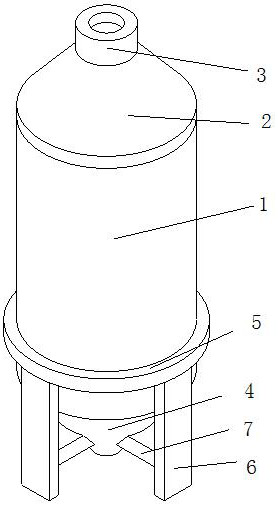

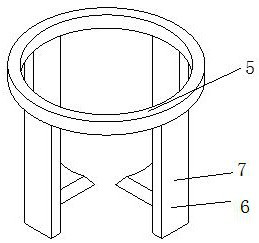

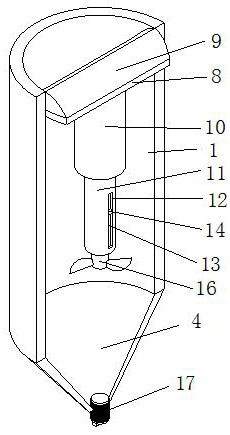

[0033] Example: such as Figure 1-Figure 4As shown, an anti-corrosion aggregate equipment for ladles includes an outer frame 1, the outer frame 1 is hollow cylindrical, the top of the outer frame 1 is provided with a top cover 2, and the top cover 2 is in the shape of a circular platform. The top wall surface is provided with a circular through hole, and the top wall surface of the top cover 2 is fixedly equipped with a feed frame 3. The feed frame 3 is in the shape of a hollow cylinder. Correspondingly, a bottom frame 4 is fixedly installed on the bottom of the outer frame 1, and a ferrule 5 is arranged outside the outer frame 1. The inner bottom wall of the ferrule 5 is fixedly connected with the bottom end of the side wall of the outer frame 1, and the bottom wall of the ferrule 5 The support legs 6 are fixedly installed, and there are four sets of support legs 6. The side walls of the four sets of support legs 6 near the center point are all fixedly installed with support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com