A kind of silver-nickel composite material and preparation method thereof

A composite material, silver-nickel technology, applied in the field of silver-based electrical contact materials, can solve the problems of poor anti-fusion welding performance, complex preparation process, difficult adjustment, etc., and achieves the effect of low cost, simple process and improved quality fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

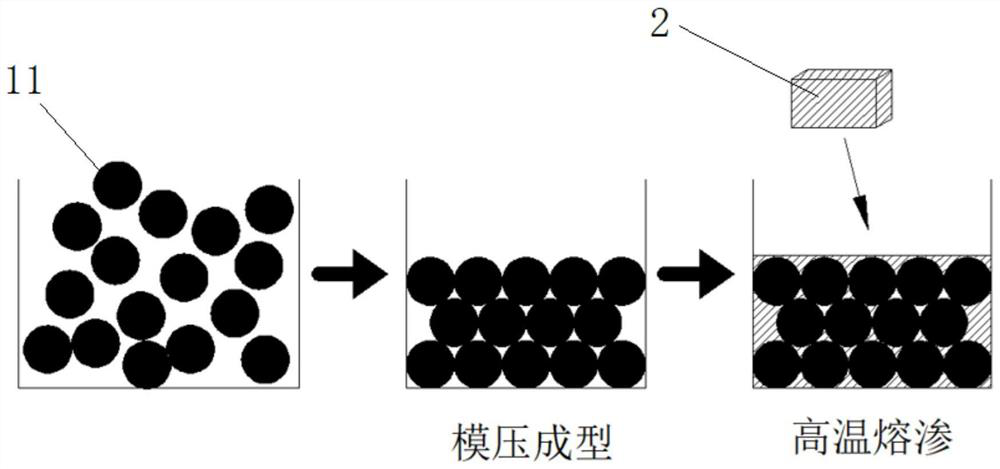

[0040]What needs to be explained here is that the preparation method of the silver-nickel composite material proposed by the present invention mainly uses two kinds of raw materials: the first kind is nickel powder or silver-nickel mixed powder whose particle size range is 0.2-200 μm; the second kind It is a silver block or a silver alloy block (a silver block refers to a pure silver block); the corresponding preparation steps mainly include two steps of molding and high temperature infiltration. Wherein, the specific preparation method is as follows:

[0041] Compression molding step: molding the raw material powder into a compact; wherein, the raw material powder is nickel powder with a particle size range of 0.2-200 μm; or the raw material powder is silver-nickel mixed powder; in the silver-nickel mixed powder, nickel powder The particle size range is 0.2-200μm.

[0042] Specifically, the compression molding pressure is 30-40Mpa, and the holding time is 0.8-1.5h.

[0043]...

Embodiment 1

[0059] In this embodiment, a silver-nickel composite material is prepared, wherein the raw materials used include nickel powder and silver nuggets with an average particle size of 80-100 mesh.

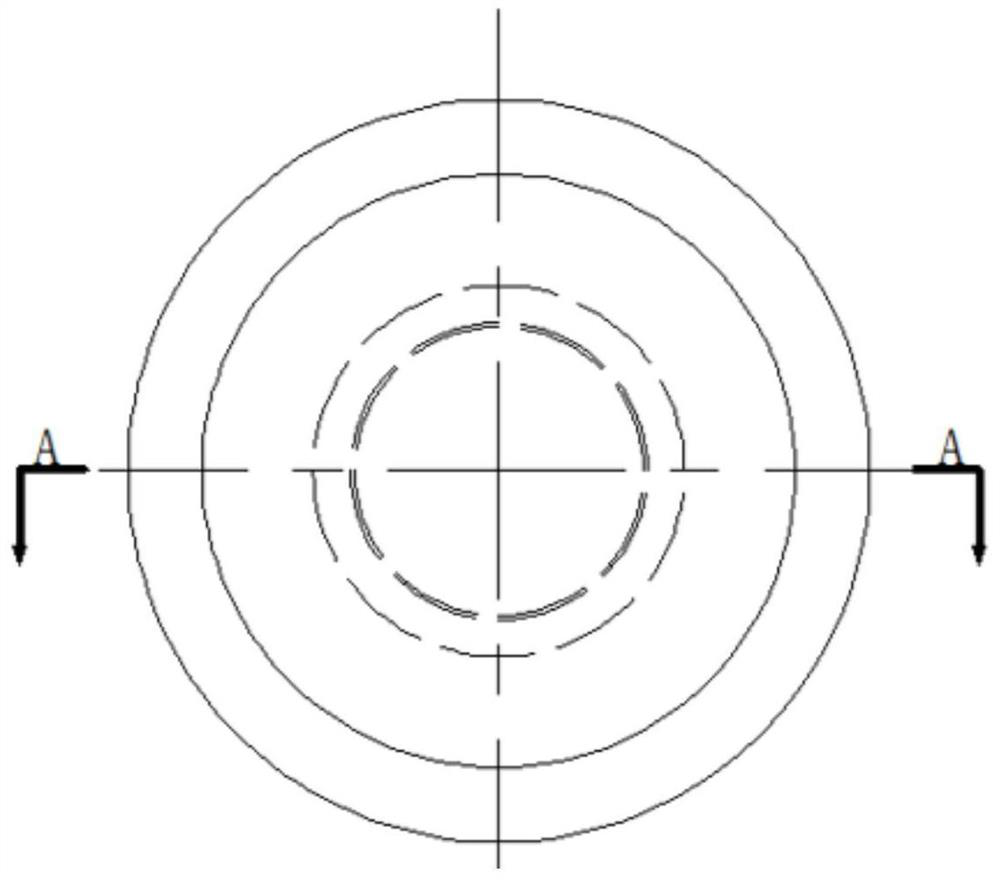

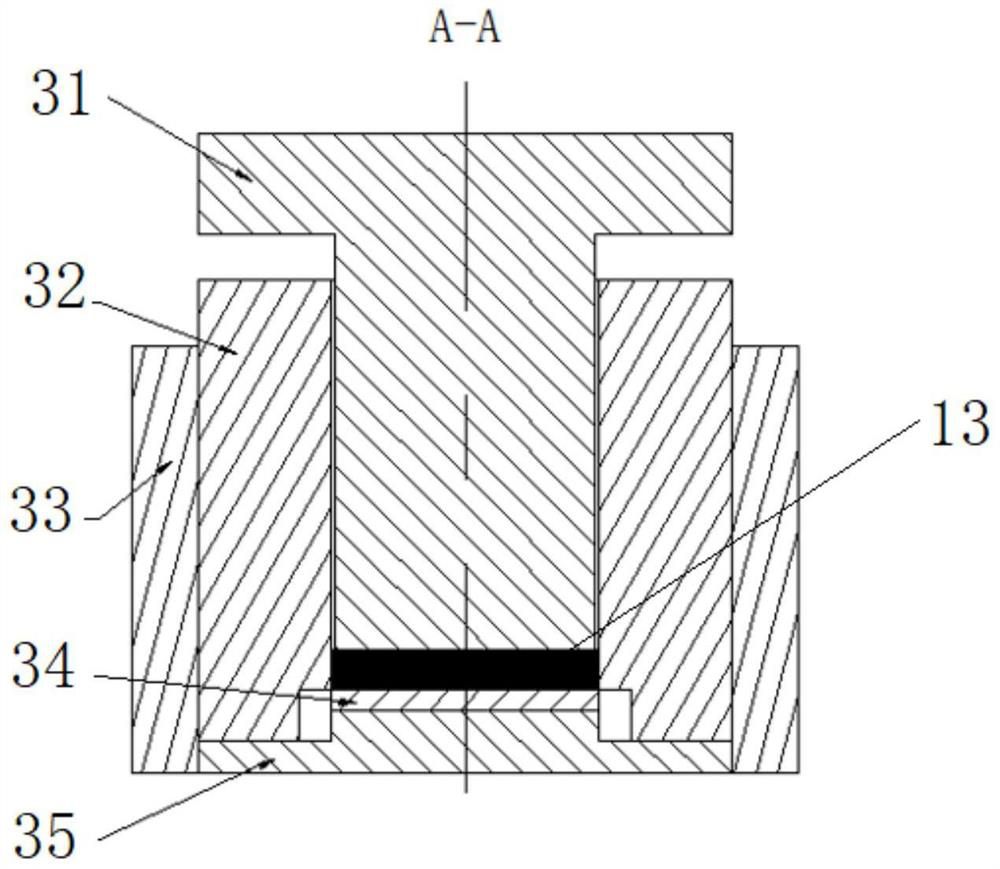

[0060] Among them, the principle of preparing silver-nickel composite materials in this embodiment can be found in figure 1 As shown, the mold used is as Figure 2A and 2B as shown in figure 1 and Figure 2A , as shown in 2B, the specific preparation steps are as follows:

[0061] Molding steps: start molding, first wipe the mould, especially the inner wall and bottom, with absorbent cotton dipped in a small amount of alcohol, and then install the die 32 and the fixing ring 33 on the base 35 . Then add 20 g of nickel powder 11 with an average particle size of 80-100 mesh into the mold cavity, and use the upper punch 31 to preliminarily flatten it. Next, adjust the stroke of the hydraulic press to the fully open state, and place the entire mold and the nickel powder 11 at the cente...

Embodiment 2

[0065] In this embodiment, a silver-nickel composite material is prepared, wherein the raw materials used include nickel powder and silver alloy (AgCu5) with an average particle size of 30-50 μm. Concrete preparation steps are as follows:

[0066] Molding steps: start molding, first use absorbent cotton dipped in a small amount of alcohol to wipe the mold, especially the inner wall and bottom, and then install the die 32 and the fixing ring 33 on the base 35, such as Figure 2A and 2B As shown, then add 20 g of nickel powder with an average particle size of 30-50 μm into the cavity of the mold, and use the upper punch 31 to initially flatten it. Next, adjust the stroke of the hydraulic press to fully open the mold, and place the entire mold and nickel powder at the center of the hydraulic press. Finally, pressurize manually to 40MPa. After maintaining the pressure for 1 hour, remove the load and adjust the upper mold base to completely open the hydraulic press, and take out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com