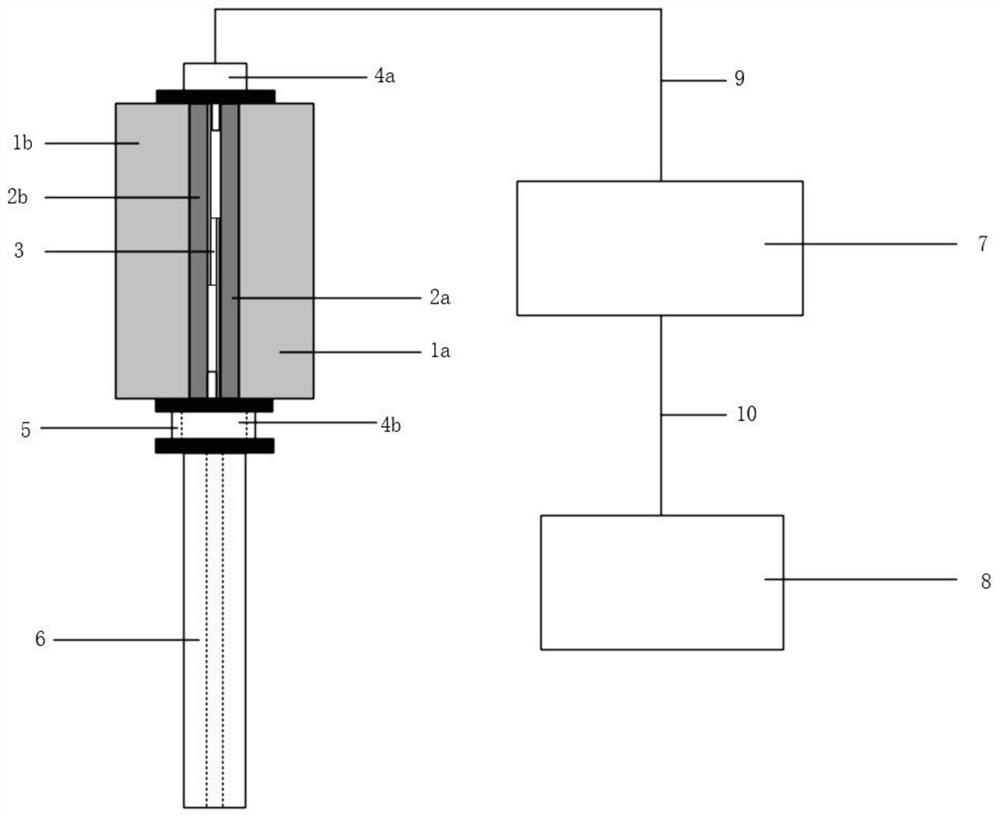

Complex permittivity test system and test method based on coaxial stripline resonator

A technology of complex permittivity and testing methods, applied in instruments, measuring devices, measuring electrical variables, etc., can solve the problems of low testing accuracy, large size of testing devices, difficult movement, etc., and achieve convenient adjustment of resonators and stable energy coupling. , the effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

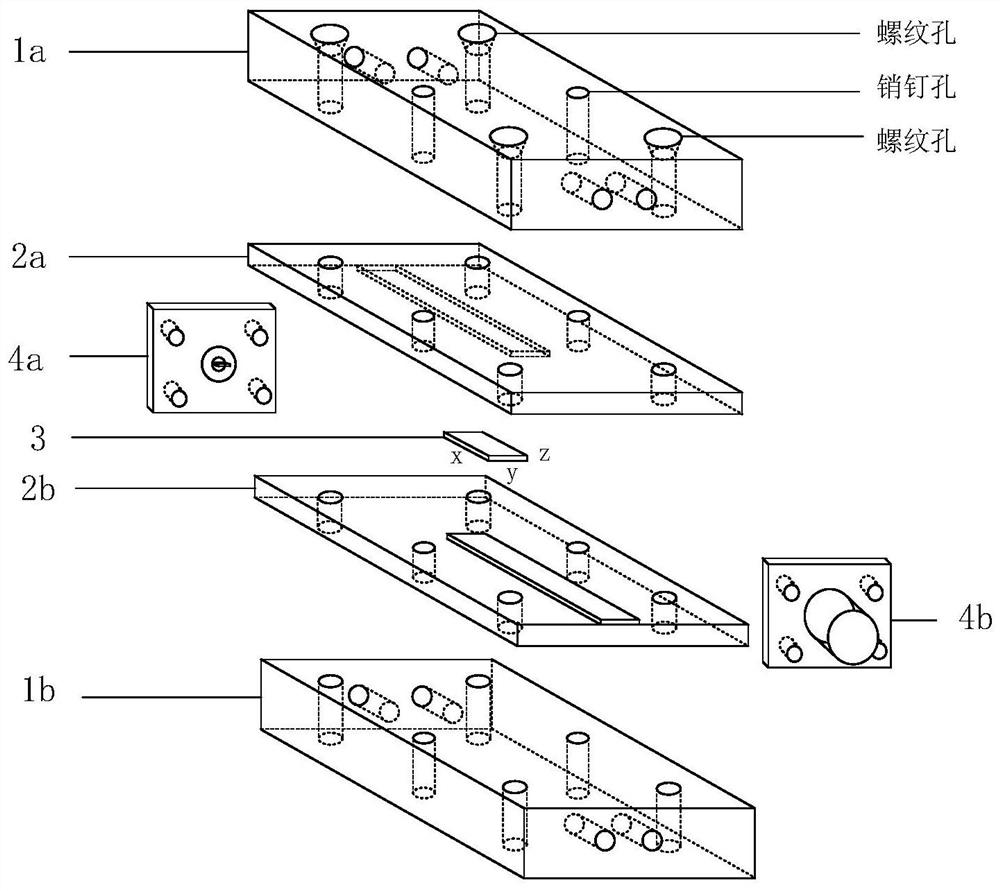

[0055] In this embodiment, the length (x) of the insulating dielectric film (3) is 4 mm, the width (y) is 2.5 mm, and the thickness (z) is 80 μm.

[0056] A method for testing the complex dielectric constant based on the testing system of the present invention, comprising the following steps:

[0057] Step 1: Place 4 kinds of calibration standard samples (deionized water, normal saline, methanol, ethylene glycol) with known complex dielectric constants on the open end of the coaxial stripline resonator, and control the vector network analysis through the program-controlled computer The instrument records the resonant frequency f of the coaxial stripline resonator when the standard sample is loaded x and quality factor Q x , and record the resonant frequency f when no sample is loaded 0 and quality factor Q 0 ;

[0058] The values of relative permittivity and loss tangent of four standard samples are as follows:

[0059]

[0060]

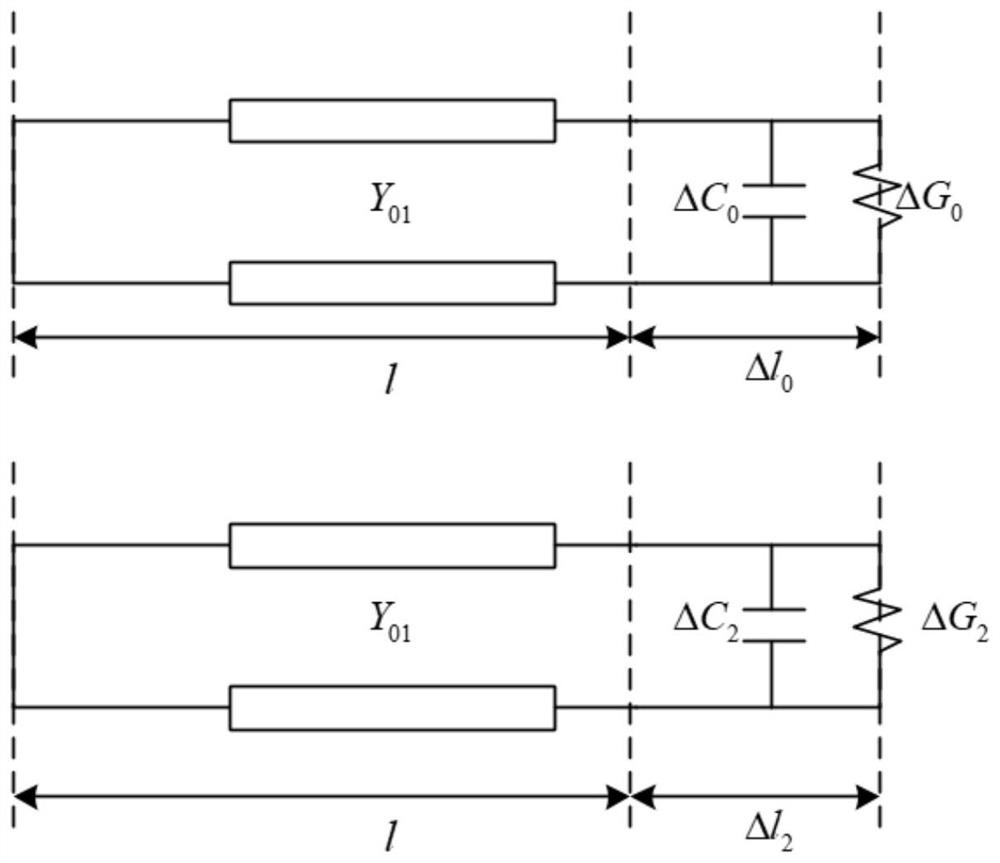

[0061] Step 2: The equivalent cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com