Zinc oxide electric bridge ultraviolet detection unit and preparation method thereof

A detection unit, zinc oxide technology, applied in the field of microelectronics, can solve the problems of large volume and high price, and achieve the effect of cost saving and easy combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of a zinc oxide bridge ultraviolet detection unit, comprising the following steps:

[0043] In the first step, the substrate is washed in acetone, absolute ethanol and ultrapure water in sequence to obtain a clean substrate, wherein the substrate is a quartz sheet or a silicon sheet with an oxide layer;

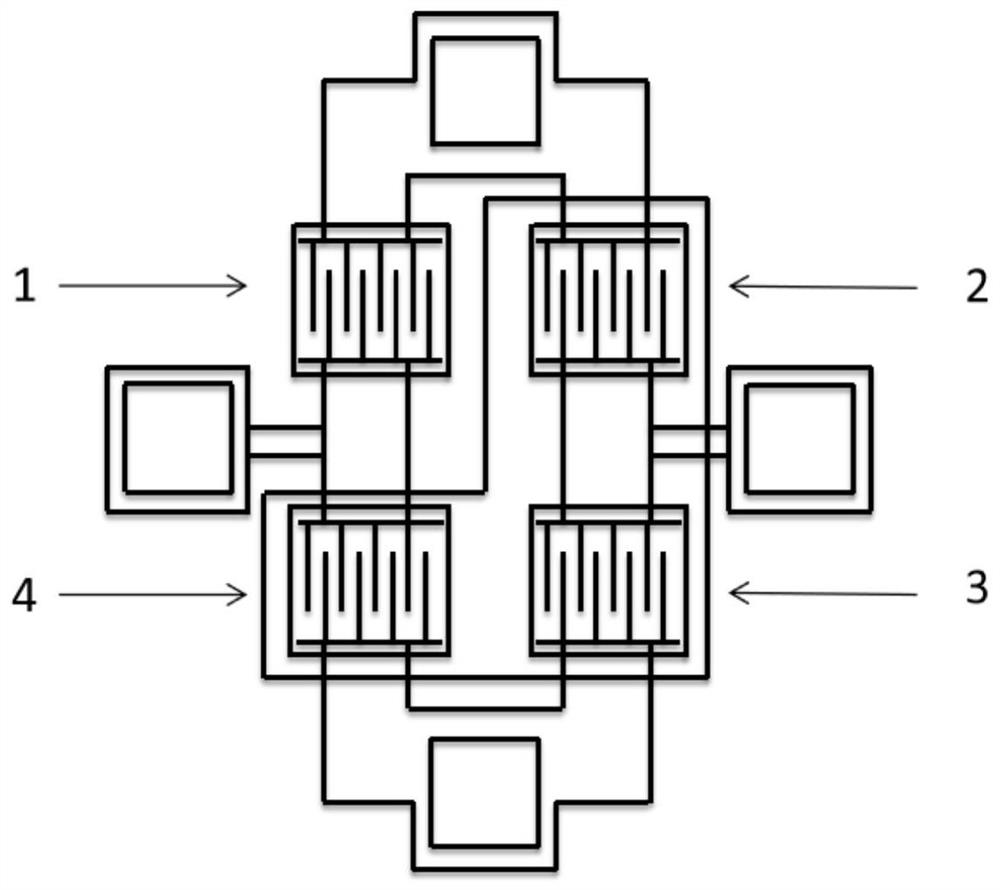

[0044] In the second step, on a clean substrate according to figure 1 The shown bridge structure is photolithographically obtained to obtain electrode patterns;

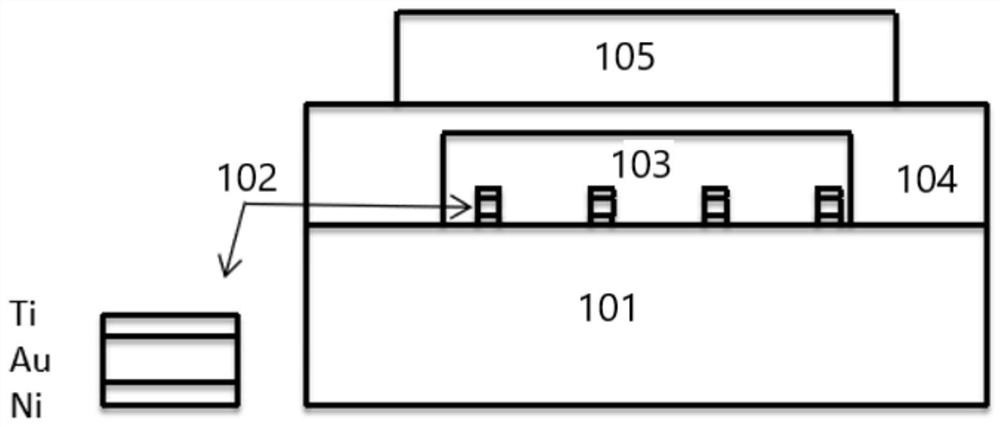

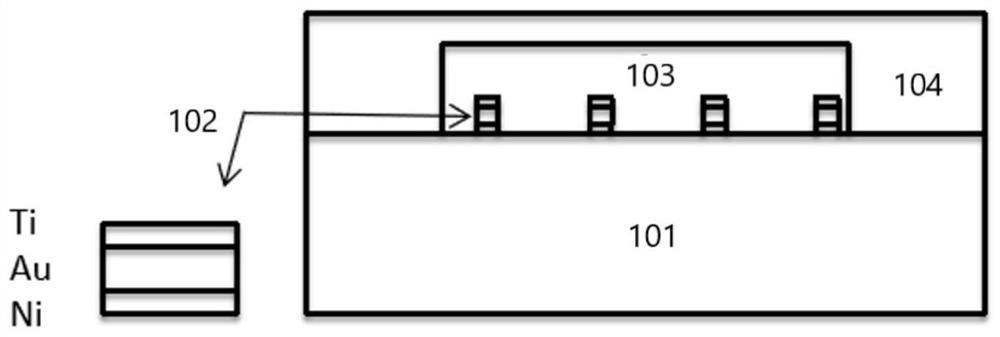

[0045] The third step is to perform electron beam evaporation on the electrode pattern to form a metal electrode layer;

[0046] The fourth step is to prepare a ZnO film by radio frequency magnetron sputtering on the metal electrode layer to obtain a zinc oxide semiconductor layer;

[0047] The fifth step is to sequentially perform photolithography and wet etching on the zinc oxide semiconductor layer to obtain a patterned zinc oxide layer;

[0048] The sixth step is to prepare SiO by RF...

Embodiment

[0056] In this embodiment, the zinc oxide bridge ultraviolet detection unit is less than 1mm 3 , UV photoresistors are MSM devices.

[0057] When using the ultraviolet detector involved in this embodiment to detect ultraviolet rays, such as Figure 4 As shown, as the intensity of ultraviolet light increases, the bridge outputs a larger voltage, therefore, the ultraviolet detector involved in the present invention can be used to detect the intensity of ultraviolet light.

[0058] like Figure 5 As shown, according to the definition of the ultraviolet-visible light suppression ratio, it is obtained that the ultraviolet-visible light suppression ratio reaches 35 in this embodiment without the need for a filter. Among them, the ultraviolet light uses a 254nm light source, and the visible light uses a 648nm light source. Make both incident light intensity 100μW / cm 2 , respectively test the corresponding photovoltage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com