Preparation method of high-molybdenum-content ferro-molybdenum powder for powder metallurgy

A powder metallurgy, molybdenum iron powder technology, applied in the field of powder material preparation, can solve major technical problems and other problems, achieve the effect of simple process flow, increase optional range, and improve powder quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

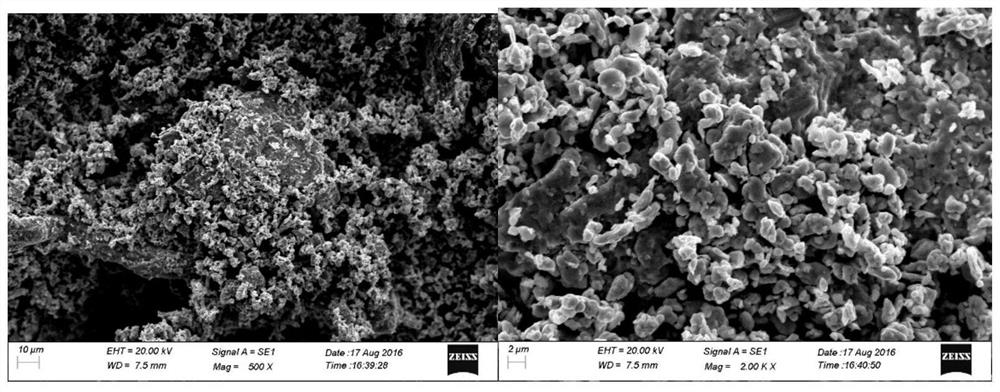

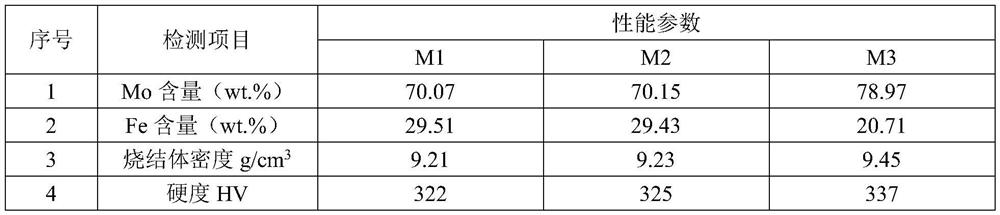

Embodiment 1

[0020] The present embodiment prepares ferromolybdenum powder according to the following steps:

[0021] Use negative 100 mesh reduced iron powder and negative 400 mesh molybdenum powder as raw materials, the mass ratio of Fe to Mo is 29:71; mix on a V-type mixer for 60 minutes; put 500g of mixed powder and grinding balls in a ball mill tank, and the The quality is 15 times of the powder mass; the ball milling speed is controlled in the range of 400r / min on the ball mill, and the ball milling time is 2h; 2 Ferromolybdenum powder was obtained after being treated in the atmosphere for 90 minutes.

Embodiment 2

[0023] The present embodiment prepares ferromolybdenum powder according to the following steps:

[0024] Use minus 100 mesh atomized iron powder and minus 400 mesh molybdenum powder as raw materials, the mass ratio of Fe and Mo is 29:71; mix on a V-type mixer for 90 minutes; put 500g of mixed powder and balls in a ball mill tank, and grind The mass of the ball is 10 times the mass of the powder; the ball milling speed is controlled within the range of 450r / min on the ball mill, and the ball milling time is 90min; 2 The ferromolybdenum powder was obtained after being treated in the atmosphere for 60 minutes.

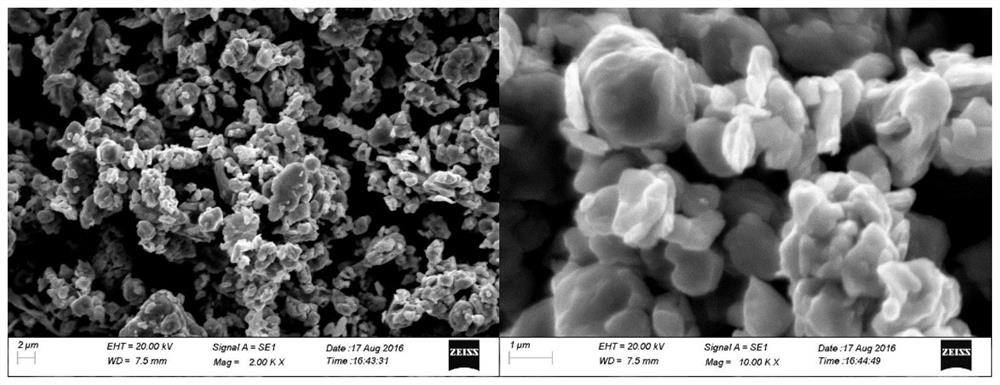

Embodiment 3

[0026] The present embodiment prepares ferromolybdenum powder according to the following steps:

[0027] Use negative 100 mesh reduced iron powder and negative 400 mesh molybdenum powder as raw materials, the mass ratio of Fe to Mo is 20:80; mix on a V-type mixer for 60 minutes; put 500g of mixed powder and grinding balls in a ball mill tank, and The quality is 20 times of the powder mass; the ball milling speed is controlled in the range of 400r / min on the ball mill, and the ball milling time is 2h; 2 Ferromolybdenum powder was obtained after being treated in the atmosphere for 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com