Synthesis process of di-tert-butyl dicarbonate

A technology for the synthesis of di-tert-butyl esters, which is applied in the preparation of organic carbonates, phosgene or haloformates, and the production of bulk chemicals. It can solve the problems of increasing the difficulty of wastewater treatment, low reaction temperature, and incomplete reactions, etc. problems, to achieve the effect of avoiding product loss, high purity and thorough reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

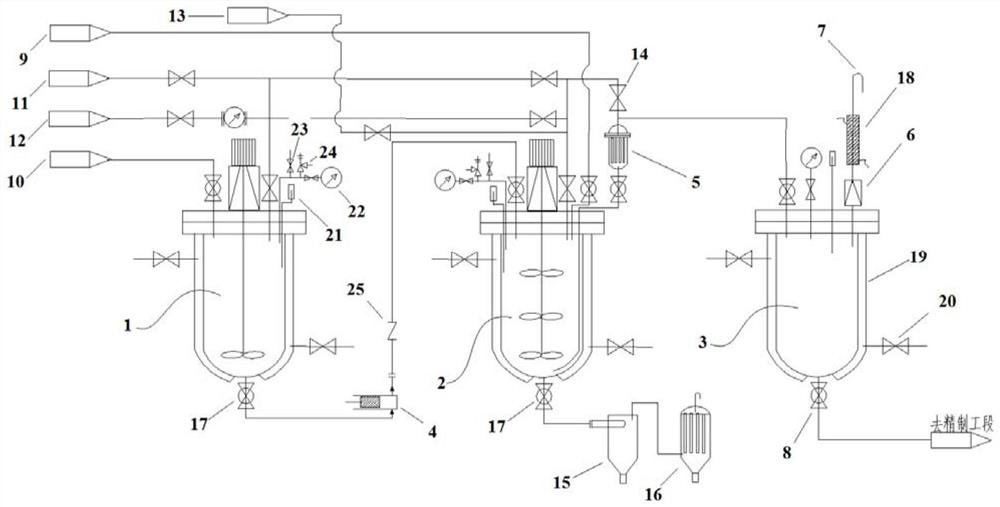

[0058] The present embodiment provides a kind of synthetic technique of di-tert-butyl dicarbonate, and this technique adopts the synthesis device of di-tert-butyl dicarbonate, such as figure 1 As shown, the synthesis device of di-tert-butyl dicarbonate comprises a dissolution kettle 1, a reactor 2 and a separation kettle 3, and the dissolution kettle 1 is connected to the feed port of the reactor 2 by a plunger pump 4; the reactor 2 is passed through a precision filter 5 Link to the feed port of the separation kettle 3, the top of the separation kettle 3 is connected to the vent pipe 7 through a pressure reducing valve 6 and vented, and the bottom of the separation kettle 3 is connected to the discharge valve 8;

[0059] The feeding port of the dissolution kettle 1 is connected with the raw material B input pipe 10;

[0060] The solid feed inlet of reactor 2 links to each other with raw material A input pipe 9;

[0061] The air inlet of dissolution kettle 1, the air inlet of ...

Embodiment 2

[0096] The present embodiment provides a kind of synthetic technique of di-tert-butyl dicarbonate, and this technique uses tert-butoxide alkali metal salt and phosgene as reaction raw material, and this technique adopts supercritical carbon dioxide as reaction raw material and solvent, in carbon dioxide super Carry out the synthesis of di-tert-butyl dicarbonate in a critical state;

[0097] The alkali metal salt of tert-butoxide is sodium tert-butoxide or potassium tert-butoxide; the phosgene compound is triphosgene, diphosgene, phosgene or tert-butyl chloroformate.

[0098] As a preferred version of this embodiment, the process is carried out in the synthesis device of di-tert-butyl dicarbonate in Example 1.

[0099] Specifically, the process includes the following steps:

[0100] Step 1, using tert-butanol alkali metal salt as raw material, taking carbon dioxide as another reactant and solvent, reacting under carbon dioxide supercritical state to generate a mixture of mono-...

Embodiment 3

[0122] The present embodiment provides a kind of synthetic technique of di-tert-butyl dicarbonate, and this technique uses tert-butoxide alkali metal salt and phosgene as reaction raw material, and this technique adopts supercritical carbon dioxide as reaction raw material and solvent, in carbon dioxide super Carry out the synthesis of di-tert-butyl dicarbonate in a critical state;

[0123] As a preferred version of this embodiment, the process is carried out in the synthesis device of di-tert-butyl dicarbonate in Example 1.

[0124] Specifically, the process includes the following steps:

[0125] Step 1, using tert-butanol alkali metal salt as raw material, taking carbon dioxide as another reactant and solvent, reacting under carbon dioxide supercritical state to generate a mixture of mono-tert-butyl carbonate alkali metal salt dissolved in supercritical carbon dioxide;

[0126] As a preferred version of this embodiment, Step 1 is carried out in the reactor 2 of the synthesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com