Rubber composition, preparation method thereof and rubber product

A rubber composition and rubber technology, applied in the field of rubber products, can solve the problems of insignificant improvement of the adhesion performance of the rubber composition, and achieve the effects of good adhesion performance and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-6

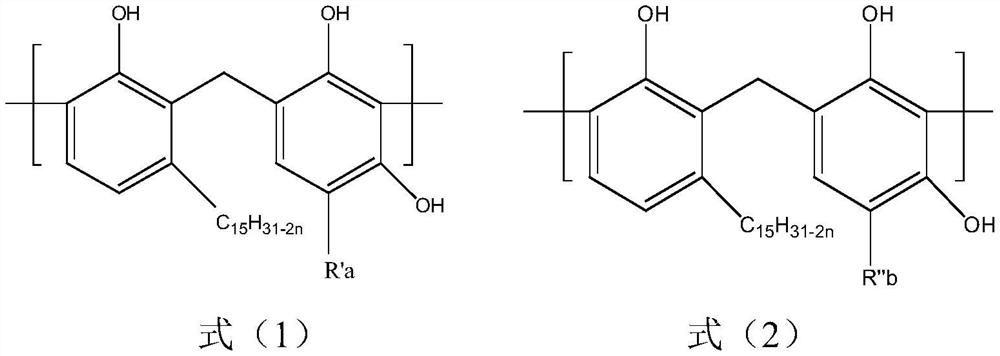

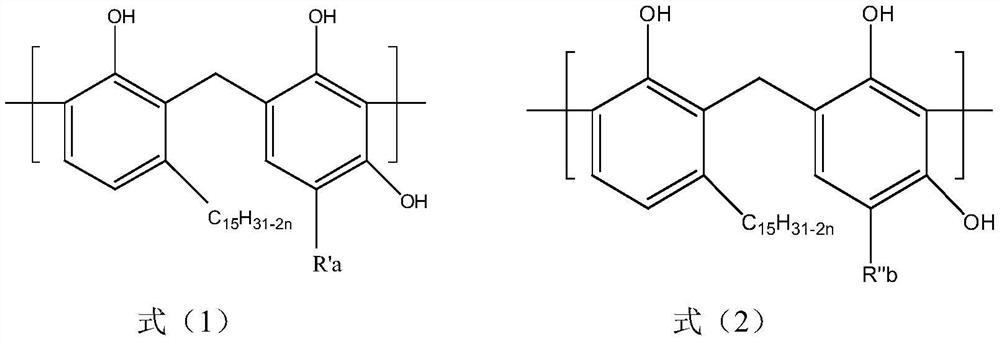

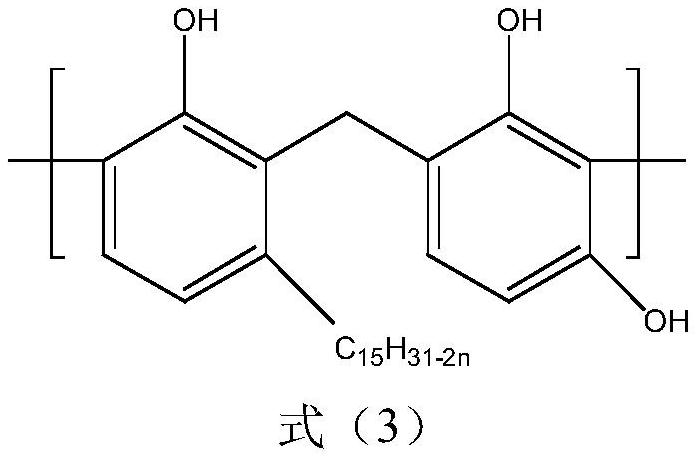

[0107] Preparation Example 1-6: Mix 0.5mol (151g) of cardanol, 30g of distilled water, 50ml of toluene and 0.55g of triethanolamine, gradually raise the temperature to 85°C, stir to dissolve, and gradually add 0.85mol (25.5g) of Solid formaldehyde, react at reflux at 98°C for 3.5h, add 1.20g of dodecylbenzenesulfonic acid to neutralize, then add 0.66mol mixed alkyl resorcinol, react at 90°C for 1h, change to distillation state and then gradually increase the temperature to 160°C, and then carry out vacuum distillation to obtain deep red mixed alkyl resorcinol modified adhesive resins, which are respectively resins 1-6; wherein, the types and contents of mixed alkyl resorcinols are shown in Table 1 shown.

[0108] The kind and content of alkyl resorcinol in table 1 preparation example 1-6

[0109]

[0110] The content of free resorcinol in the preparation example 1-6 of table 2

[0111]

[0112] Preparation example of alkylphenol sulfide

[0113] Add 79.2g (0.4mol) of ...

Embodiment 1-6 and comparative example 1

[0143] Embodiment 1-6 and comparative example 1: the preparation of rubber composition is as follows:

[0144]Add rubber, carbon black, zinc oxide, and stearic acid into a 1.6-liter Banbury internal mixer (produced by FARREL Company) and mix, and heat up to 155°C while mixing for 6 minutes, then cool to about 90°C; then add accelerator CZ, Cobalt salt, anti-aging agent RD, S, HMMM, mixed alkyl resorcinol modified cardanol-formaldehyde binding resin, the above mixture was mixed at a temperature of 50 ° C for 5 minutes, so as to obtain an unvulcanized rubber composition; The rubber composition was molded on a BH-25T plate vulcanizer (produced by Bohai Experimental Machinery Factory, Zhenwu Town, Jiangdu District) to make a flat or thin vulcanized rubber composition. The specific formula is shown in Table 3.

[0145] The raw material ratio of rubber composition in table 3 embodiment 1-6 and comparative example 1

[0146]

[0147] Adhesive strength test result (KN / m) in table ...

Embodiment 7-10

[0151] Embodiment 7-10: The difference from Example 1 is that the alkylphenol sulfide and the alkylphenol modified amino resin are added and mixed with the mixed alkylresorcinol modified cardanol-formaldehyde binding resin, The formulation of the rubber composition is shown in Table 5.

[0152] The raw material ratio of rubber composition in table 5 embodiment 7-10

[0153]

[0154] Adhesive strength test result (KN / m) among table 6 embodiment 7-10

[0155]

[0156] The detection results of vulcanization performance and mechanical properties in Table 7 embodiment 5 and embodiment 7-10

[0157]

[0158] Shown in conjunction with table 6 and table 7, by comparing with embodiment 7-8, the bonding performance of embodiment 5 is far higher than the bonding performance index of embodiment 7-8, therefore, add mixed alkyl resorcinol separately The adhesive performance of the rubber composition of the phenol-modified cardanol-formaldehyde adhesive resin is better than that o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com