Method for preparing modified aramid pulp/PMMA composite material through supercritical carbon dioxide polymerization

A technology for modifying aramid fibers and composite materials, which is applied in the production of bulk chemicals, fiber types, textiles, and papermaking, and can solve problems such as difficult dispersion, low density, and easy coalescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

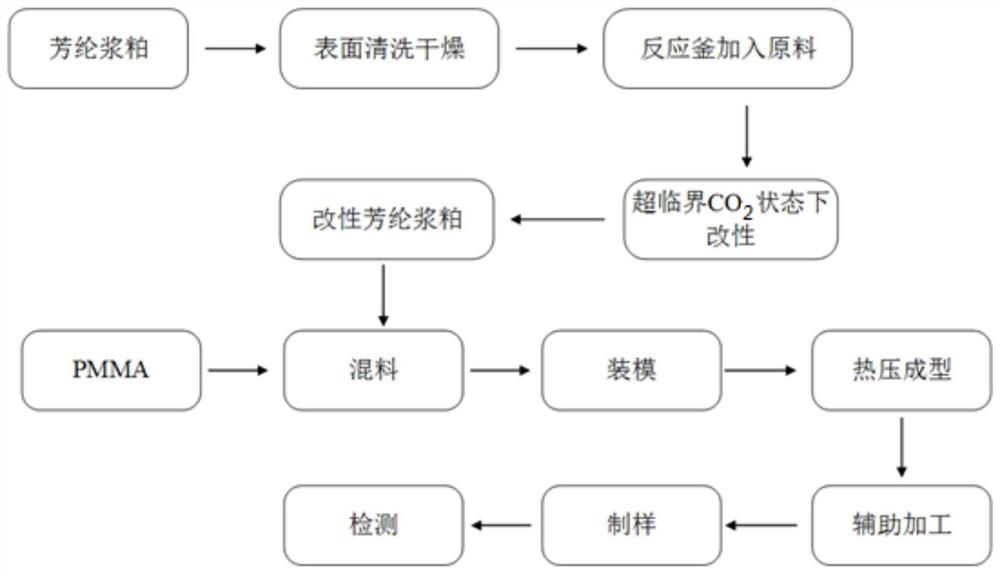

[0037] A method for preparing modified aramid pulp / PMMA composite material by supercritical carbon dioxide polymerization, such as figure 1 shown, the steps are as follows:

[0038] (1) Put a certain amount of dried Kevlar29 aramid fiber pulp into the reactor at room temperature (25°C), then add a certain amount of liquid monomer MMA and initiator (dibenzoyl peroxide), and seal the Reactor; the mass ratio of MMA to aramid pulp is 1:3; the mass ratio of initiator to MMA is 1:100;

[0039] (2) Fill CO into the reactor 2 After the gas reaches a pressure of 0.5MPa, vacuumize, repeat the inflation-vacuum operation 3 times, and exhaust the air in the kettle and pipeline;

[0040] (3) Fill CO into the reactor 2 After the gas reaches a pressure of 18MPa, the temperature in the kettle is raised to 70°C at a rate of 5°C / min, so that the CO2 in the kettle is increased. 2 After reaching the supercritical state, the modified aramid pulp is obtained after 20h of heat preservation;

[0...

Embodiment 2

[0058] A method for preparing modified aramid pulp / PMMA composite material by supercritical carbon dioxide polymerization, the steps are as follows:

[0059] (1) Put a certain amount of dried Kevlar49 aramid fiber pulp into the reaction kettle at room temperature (26°C), and then add a certain amount of liquid monomer MMA and initiator (dodecanoyl peroxide) to block the reaction kettle; the mass ratio of MMA to aramid pulp is 2:3; the mass ratio of initiator to MMA is 1:80;

[0060] (2) Fill CO into the reactor 2 After the gas reaches a pressure of 0.5MPa, vacuumize, repeat the inflation-vacuum operation 3 times, and exhaust the air in the kettle and pipeline;

[0061] (3) Fill CO into the reactor 2 After the gas reaches a pressure of 20MPa, the temperature in the kettle is raised to 75°C at a rate of 8°C / min, so that the CO2 2 After reaching the supercritical state, the modified aramid fiber pulp was obtained after 24 hours of heat preservation;

[0062] (4) stirring the ...

Embodiment 3

[0066] A method for preparing modified aramid pulp / PMMA composite material by supercritical carbon dioxide polymerization, the steps are as follows:

[0067] (1) put a certain amount of dried Kevlar129 aramid fiber pulp into the reactor at room temperature (27 ° C), then add a certain amount of liquid monomer MMA and initiator (potassium persulfate), and close the reactor; The mass ratio of MMA to aramid pulp is 1:1; the mass ratio of initiator to MMA is 1:60;

[0068] (2) Fill CO into the reactor 2 After the gas reaches a pressure of 0.5MPa, vacuumize, repeat the inflation-vacuum operation 3 times, and exhaust the air in the kettle and pipeline;

[0069] (3) Fill CO into the reactor 2 After the gas reaches a pressure of 20MPa, the temperature in the kettle is raised to 75°C at a rate of 10°C / min, so that the CO2 2 After reaching the supercritical state, the modified aramid pulp was obtained after 22h of heat preservation;

[0070] (4) stirring the modified aramid fiber pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com