Method for improving anaerobic digestion of waste oil and fat to produce methane through saponification pretreatment

An anaerobic digestion, waste oil technology, applied in waste fuel, fermentation and other directions, can solve the problems of reducing microorganisms, reducing the rate of methane production, sludge flotation and scouring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a kind of preparation of calcium soap and the method for improving anaerobic methanogenesis of waste oil and fat, specifically comprise the following steps:

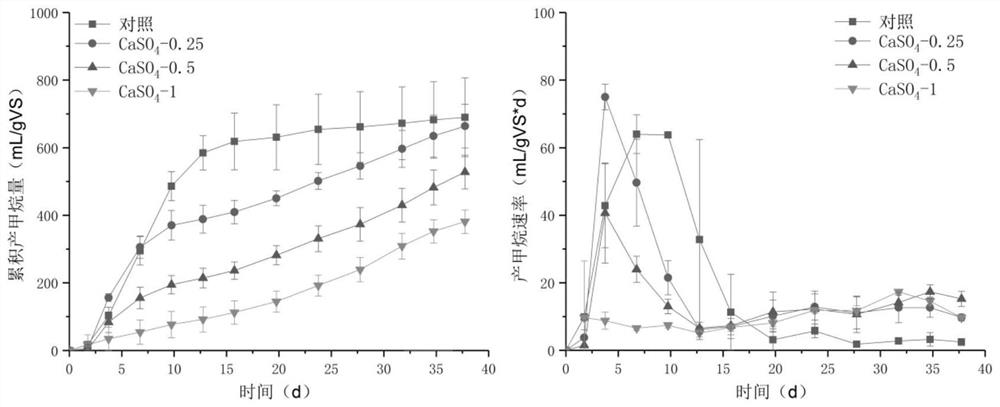

[0030] This example uses CaSO 4 As a source of calcium, Ca 2+ Three ratios with LCFAs, respectively 0.25, 0.5, 1 (mol / mol) to prepare calcium soap.

[0031] At room temperature, first add 5mL of sodium hydroxide solution (1mol / L) to a 100mL beaker, then add 5g of rapeseed oil to hydrolyze at 200rpm for 10min, and then add the corresponding amount of CaSO 4 , where Ca 2+ : LCFAs=1 This group added 5ml of ultrapure water (easy to stir), and finally sealed the mouth of the beaker with tinfoil, and stirred at 450rpm.

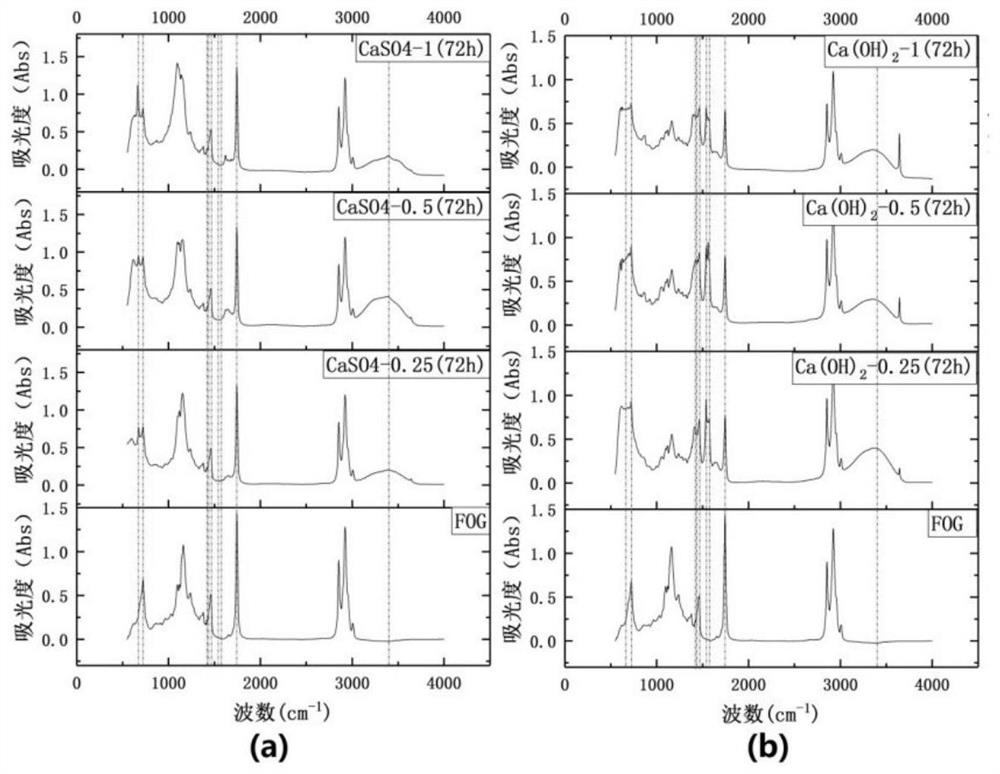

[0032] Take a small amount of generated samples at regular intervals and scan them with a Fourier transform infrared spectrometer (FTIR-HATR), until there are obvious characteristic peaks of calcium soap, stop stirring, and generate calcium soap. (a) type calcium soap...

Embodiment 2

[0036] The present embodiment provides a kind of preparation of calcium soap and the method for improving anaerobic methanogenesis of waste oil and fat, specifically comprise the following steps:

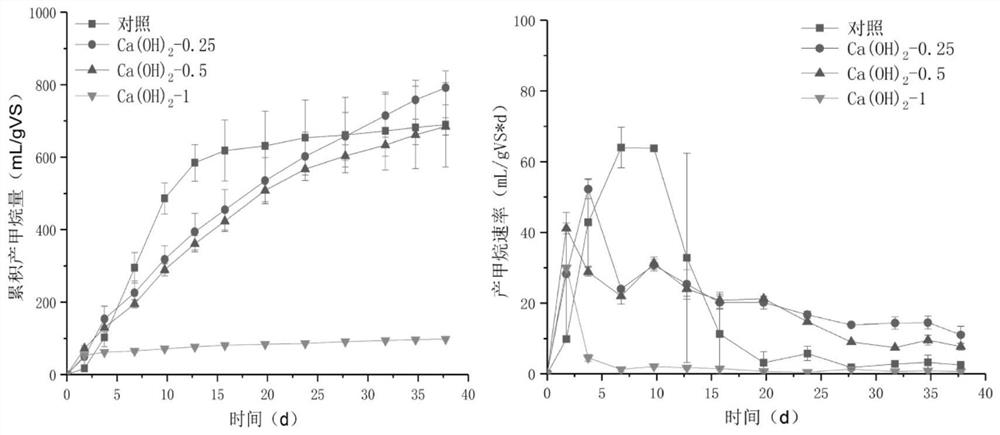

[0037] This embodiment adopts Ca(OH) 2 As a source of calcium, Ca 2+ Three ratios with LCFAs, respectively 0.25, 0.5, 1 (mol / mol) to prepare calcium soap.

[0038] At room temperature, first add 5mL of sodium hydroxide solution (1mol / L) to a 100mL beaker, then add 5g of rapeseed oil to hydrolyze at 200rpm for 10min, and then add the corresponding amount of Ca(OH) to the beaker 2 , and finally seal the mouth of the beaker with tinfoil, and stir with 450rpm rotating speed.

[0039] Take a small amount of generated samples at regular intervals and scan them with a Fourier transform infrared spectrometer (FTIR-HATR), until there are obvious characteristic peaks of calcium soap, stop stirring, and generate calcium soap. (b) type calcium soap spectrum as shown figure 1 (b) shown.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com