Mofs-derived porous carbon-coated sheet carbonyl iron composite absorbing material and preparation method

A composite wave absorbing material, carbonyl iron technology, applied in the preparation/purification of carbon, carbonyl iron, electrical components, etc., to achieve the effects of low cost, improved electromagnetic wave loss capability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

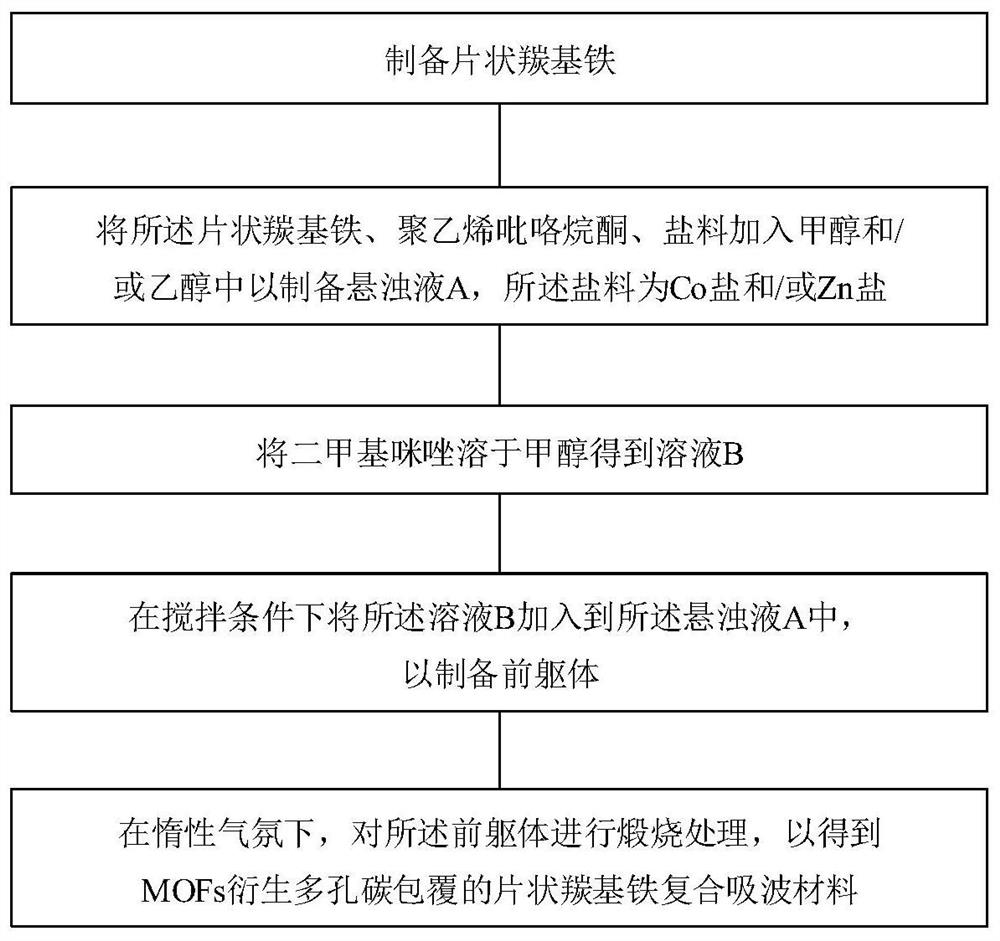

[0038] See figure 1 , figure 1 A flow chart of a preparation method of a MOFs-derived porous carbon-coated sheet carbonyl iron composite wave absorbing material provided in the embodiment of the present invention. The invention provides a preparation method of a MOFs-derived porous carbon-coated sheet carbonyl iron composite wave absorbing material, the preparation method comprising the following steps:

[0039] Step 1. Preparation of flaky iron carbonyl.

[0040] Step 1.1, select spherical carbonyl iron;

[0041] In step 1.2, spherical carbonyl iron is ball-milled by a mechanical ball milling method to prepare flake carbonyl iron.

[0042] Specifically, using spherical carbonyl iron as a raw material, a mechanical ball milling method is used to prepare flake carbonyl iron.

[0043] Step 2, adding flaky carbonyl iron, polyvinylpyrrolidone, and salt material to methanol and / or ethanol to prepare suspension A, where the salt material is Co salt and / or Zn salt.

[0044] Spec...

Embodiment 2

[0067] This embodiment provides, on the basis of the first embodiment, a preparation method of a sheet-like carbonyl iron composite wave absorbing material coated with MOFs-derived porous carbon, and the preparation method includes:

[0068] Step 1. Preparation of flaky iron carbonyl.

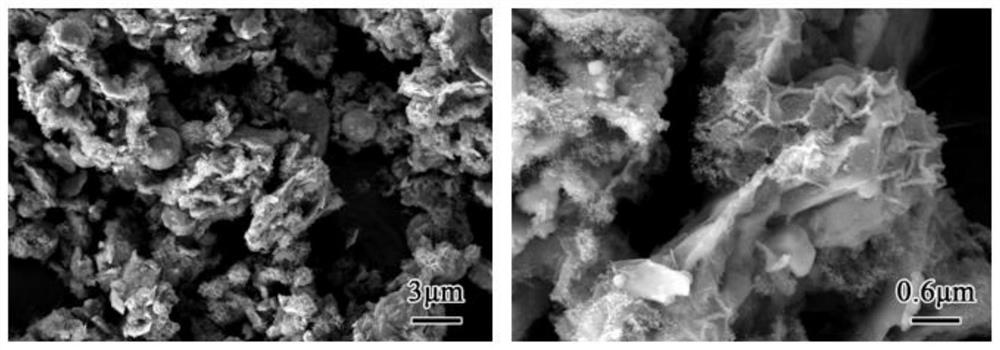

[0069] Specifically, 200g of stainless steel balls with a diameter of 6mm and 8g of carbonyl iron powder were added to a 100mL stainless steel ball mill at a ratio of 25:1 to the ball-to-material ratio, and then 0.01g of surfactant calcium stearate and 40mL of acetone as a ball milling medium were added respectively. Then, high-energy ball milling at a fixed speed of 375 r / min for 11 h was carried out on a planetary ball mill. After separation, washing and drying, flake carbonyl iron was obtained.

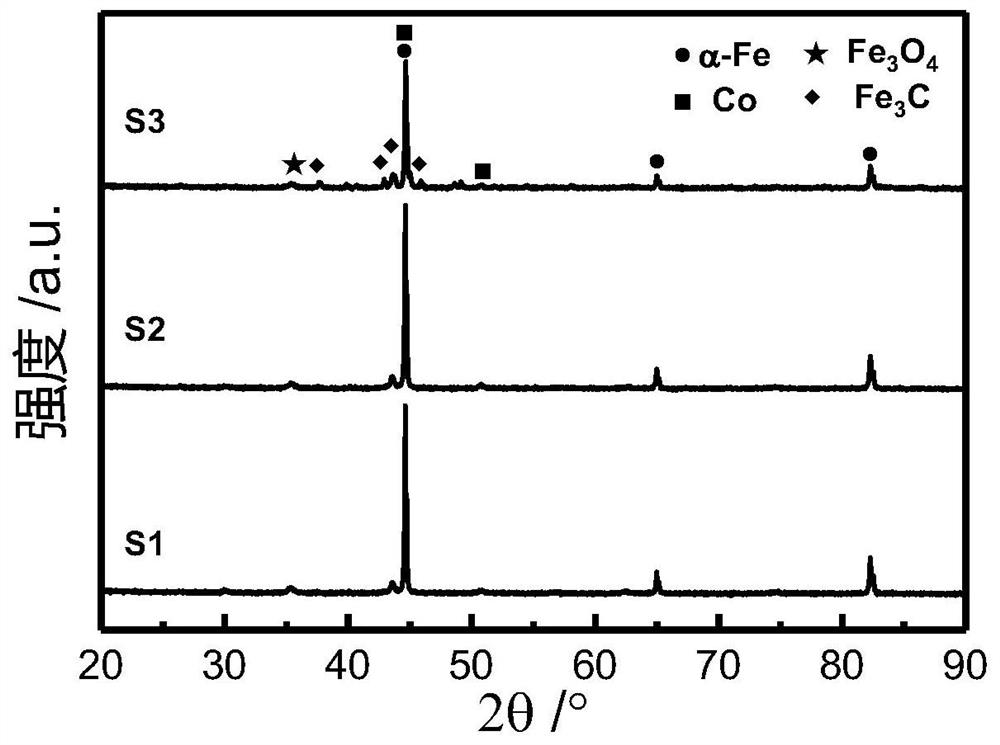

[0070] Step 2. Combine 2 g of the flaky carbonyl iron prepared in step 1, 1 g of polyvinylpyrrolidone (K30), 7.5 mmol of Co(NO 3 ) 2 ·6H 2 O was added to 80 mL of methanol, followed by sonication...

Embodiment 3

[0074] This embodiment provides another specific preparation method of the MOFs-derived porous carbon-coated sheet carbonyl iron composite wave absorbing material on the basis of the first embodiment, and the preparation method includes:

[0075] Step 1. Preparation of flaky iron carbonyl.

[0076] Specifically, 200g stainless steel balls with a diameter of 6mm and 8g carbonyl iron powder were added to a 100mL stainless steel ball mill at a ball-to-material ratio of 25:1, and then 0.01g of surfactant calcium stearate and 40mL of acetone, a ball milling medium, were added respectively. High-energy ball milling at a fixed speed of 375r / min on a planetary ball mill for 11h, after separation, washing and drying, flake carbonyl iron is obtained.

[0077] Step 2. Combine 2 g of the flaky carbonyl iron prepared in step 1, 1 g of polyvinylpyrrolidone (K30), 5.62 mmol of Co(NO 3 ) 2 ·6H 2 O and 1.88mmol Zn(NO 3 ) 2 ·6H 2 O was added to 80 mL of methanol, followed by sonication an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com