Whole-course multi-section synergetic sterilization and fresh-keeping method for shredded Qiongzhuea tumidinoda Hsueh bamboo shoots

A whole-process technology of shredded bamboo shoots, which is applied in the field of multi-stage collaborative sterilization and fresh-keeping technology and processing of special raw materials for pretreatment of shredded bamboo shoots in Sichuan cuisine. Safe to eat and rich in nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Clean the excavated fresh Qiong bamboo shoots with a fully automatic spray cleaning machine. After cleaning, the cleaned Qiong bamboo shoots are blanched with hot water at 98-100°C for 4 minutes, and the blanching water is replaced every two minutes. The blanched bamboo shoots are cooled to room temperature by spraying with running water, and the water is drained through the vibrating screen assembly line.

[0027] Use a sheller to peel off the shells of the bamboo shoots, manually remove the bamboo shoots, cut off the old roots, wash them with running water on a bubble cleaner to remove impurities such as bamboo shoots, and put the washed bamboo shoots into a blanching and killing machine for 30 minutes of high-temperature cooking Finishing treatment (temperature in the range of 95-100°C), naturally cooling in normal temperature flowing water after finishing.

[0028]After cooling, soak the whole or half-cut bamboo shoots in the compound color protection solution for 3...

Embodiment 2

[0032] Clean the excavated fresh Qiong bamboo shoots with a fully automatic spray cleaning machine. After cleaning, the cleaned Qiong bamboo shoots are blanched with hot water at 98-100°C for 5 minutes, and the blanching water is replaced every two minutes. The blanched bamboo shoots are cooled to room temperature by spraying with running water, and the water is drained through the vibrating screen assembly line.

[0033] Use a sheller to peel off the shells of the bamboo shoots, manually remove the bamboo shoots, cut off the old roots, wash them with running water on a bubble cleaner to remove impurities such as bamboo shoots, and put the washed bamboo shoots into a blanching and killing machine for 30 minutes of high-temperature cooking Finishing treatment (95-100 ℃), naturally cool in normal temperature flowing water after finishing.

[0034] After cooling, soak the whole or half-cut bamboo shoots in the compound color protection solution for 30 minutes. The formula of the ...

Embodiment 3

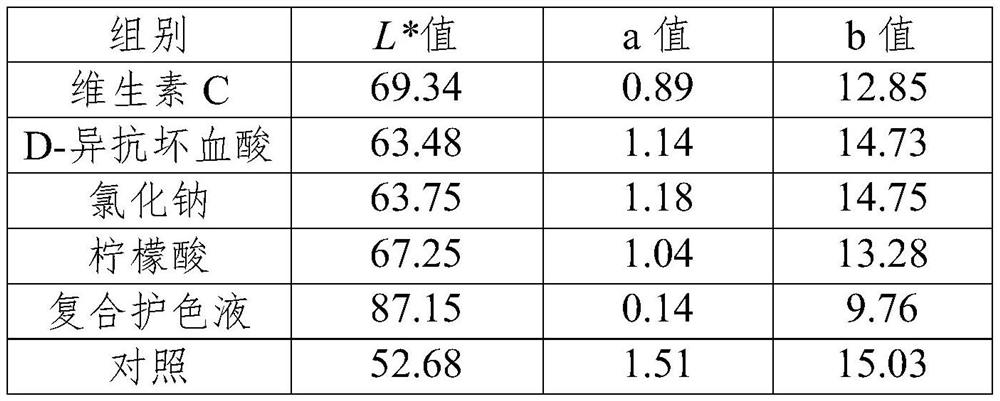

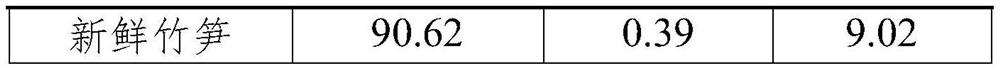

[0038] Get the bamboo shoots after the enzymatic treatment in Example 1 and place them in different color-protecting solutions to soak for 30 minutes, drain, carry out ultra-high pressure treatment after vacuum packaging, and take out the finished product after placing it at room temperature for 15 days, and use a precision colorimeter to test the bamboo shoots under dark conditions. The color of the same position was measured, and the measurement was repeated three times for each group, and the average value was taken. The results are shown in Table 1. The control group is a product that has not been soaked to protect the color.

[0039] Table 1 Effect of different color-protecting agents on the color of bamboo shoots

[0040]

[0041]

[0042] As can be seen from Table 1, the bamboo shoots without color protection (control group) were severely browned after being placed for 15 days; the color protection effect was not significant with a single color protection solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com