Antibacterial ABS plastic and preparation method thereof

A technology of ABS plastic and ABS resin, which is applied in the field of antibacterial ABS plastic and its preparation, can solve problems such as complicated process, easy to produce drug resistance, difficult processing, etc., and achieve simple operation, easy industrial promotion, enhanced antibacterial and antibacterial properties The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

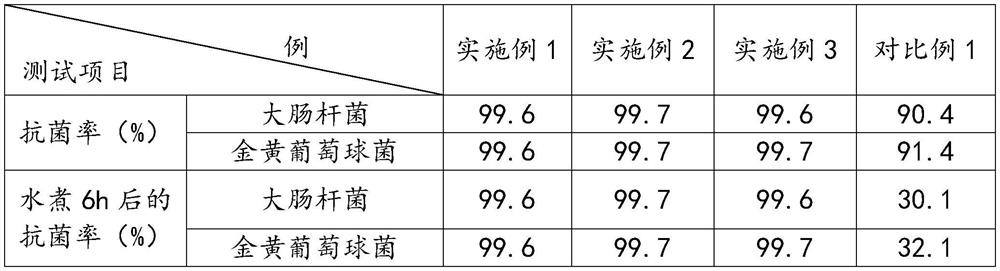

Examples

Embodiment 1

[0038] An antibacterial ABS plastic, comprising the following raw materials in parts by weight: 90 parts of ABS resin, 3 parts of polyurethane quaternary ammonium salt, 3 parts of plasticizer, and 3 parts of auxiliary agent;

[0039] Its preparation method comprises the following steps:

[0040] Step 1: Take ABS resin, polyurethane quaternary ammonium salt, plasticizer, and auxiliary agent according to the weight ratio and add them to a high-speed blender for premixing for 10 minutes to obtain a premix, wherein the plasticizer is dibutyl phthalate, The auxiliary agent is a 1:1:1 mixture of antioxidant, lubricant and heat stabilizer, wherein the antioxidant is antioxidant 1010, the lubricant is paraffin, and the heat stabilizer is zinc stearate;

[0041] Step 2: Add the premixed material obtained in Step 1 into an extruder, melt extrusion, granulate and dry to obtain an antibacterial ABS plastic, wherein the extrusion conditions are 170°C in the first zone and 180°C in the seco...

Embodiment 2

[0046] An antibacterial ABS plastic, comprising the following raw materials in parts by weight: 100 parts of ABS resin, 4 parts of polyurethane quaternary ammonium salt, 4 parts of plasticizer, and 4 parts of auxiliary agent;

[0047] Its preparation method comprises the following steps:

[0048] Step 1: Take ABS resin, polyurethane quaternary ammonium salt, plasticizer, and auxiliary agent according to the weight ratio and add them to a high-speed blender for premixing for 10 minutes to obtain a premix, wherein the plasticizer is dibutyl phthalate, The auxiliary agent is a 1:1:1 mixture of antioxidant, lubricant and heat stabilizer, wherein the antioxidant is antioxidant 1010, the lubricant is paraffin, and the heat stabilizer is zinc stearate;

[0049] Step 2: Add the premixed material obtained in Step 1 into the extruder, perform melt extrusion, granulation and drying, and obtain an antibacterial ABS plastic, wherein the extrusion conditions are 200°C in the first zone and ...

Embodiment 3

[0054] An antibacterial ABS plastic, comprising the following raw materials in parts by weight: 120 parts of ABS resin, 5 parts of polyurethane quaternary ammonium salt, 5 parts of plasticizer, and 5 parts of auxiliary agent;

[0055] Its preparation method comprises the following steps:

[0056] Step 1: Take ABS resin, polyurethane quaternary ammonium salt, plasticizer, and auxiliary agent according to the weight ratio and add them to a high-speed blender for premixing for 3 minutes to obtain a premix, wherein the plasticizer is dibutyl phthalate, The auxiliary agent is a 1:1:1 mixture of antioxidant, lubricant and heat stabilizer, wherein the antioxidant is antioxidant 1010, the lubricant is paraffin, and the heat stabilizer is zinc stearate;

[0057] Step 2: Add the premixed material obtained in Step 1 into the extruder, melt extrusion, granulate and dry to obtain an antibacterial ABS plastic, wherein the extrusion conditions are 190°C in the first zone and 190°C in the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com