Method for improving quality of functional onion vinegar in brewing process

A quality improvement and functional technology, applied in the field of quality improvement in the brewing process of functional onion vinegar, can solve the problems of lack of yeast fermentation flavor and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

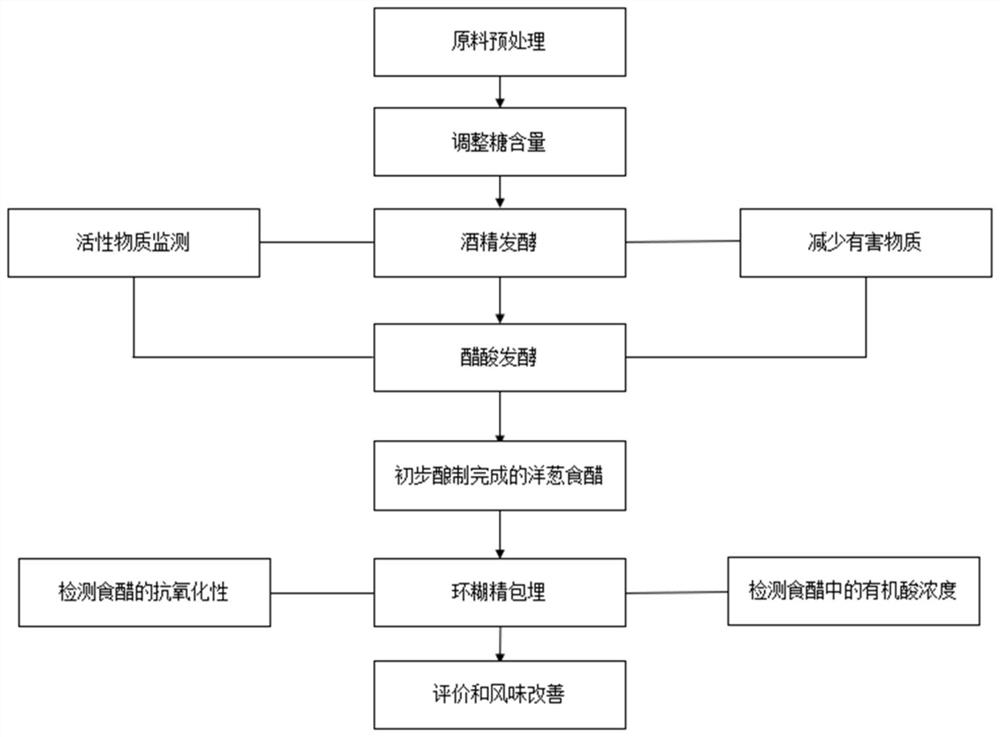

Method used

Image

Examples

Embodiment 1

[0036] A method for improving quality in the brewing process of functional onion vinegar, comprising the following brewing process,

[0037] S1 raw material pretreatment: select fresh onions, wash, remove the head, cut the tail, cut, soak in citric acid, heat and boil the juice at 80°C for 3 hours, then filter and extract with 1 μm mesh to make onion juice extract;

[0038] S2 Adjust the sugar content: add liquefaction enzyme after steaming and gelatinizing the corn, and liquefy at 90°C for 15 minutes; add 0.5% glucoamylase into the liquefaction liquid, and saccharify at 60°C for 30 minutes, use the above corn sugar solution to adjust the sugar content of the above onion juice extract to 10 , adjust the pH value of the onion juice extract to 6.0;

[0039]S3 Alcoholic fermentation: use yeast Saccharamyces cerevisiae ATCC9763 as the strain, add 1kg / 10t of active dry yeast to warm water at 35°C, mix well, let stand, stir gently every 10 min, let stand for 20min, and then use YM m...

Embodiment 2

[0046] A brewing process of functional onion vinegar is characterized in that it comprises the following steps:

[0047] S1 Raw material pretreatment: select fresh onions, wash, remove the head, cut the tail, cut, soak in citric acid, heat and boil the juice at 90°C for 2 hours, then filter and extract with a 510μm mesh to make onion juice extract;

[0048] S2 Adjust the sugar content: add liquefaction enzyme after steaming and gelatinizing the corn, and liquefy at 90°C for 15 minutes; add 0.5% glucoamylase into the liquefaction liquid, and saccharify at 60°C for 30 minutes, and use the above corn sugar solution to adjust the sugar content of the above onion juice extract to 14 , adjust the pH value of the onion juice extract to 6.2;

[0049] S3 Alcoholic fermentation: use yeast Saccharamyces cerevisiae ATCC9763 as the strain, add 1kg / 10t of active dry yeast to the 5% sugar solution at 40°C, mix well, let stand, stir gently once every 10 min, let stand for 25min, Then use YM ...

Embodiment 3

[0056] A brewing process of functional onion vinegar is characterized in that it comprises the following steps:

[0057] S1 raw material pretreatment: select fresh onions, wash, remove the head, cut the tail, cut, soak in citric acid, heat and boil the juice at 100°C for 1 hour, then filter and extract with a 10μm mesh to make onion juice extract;

[0058] S2 Adjust the sugar content: add liquefaction enzyme after steaming and gelatinizing the corn, and liquefy at 90°C for 15 minutes; add 0.5% glucoamylase to the liquefaction liquid, and saccharify at 60°C for 30 minutes, use the above corn sugar solution to adjust the sugar content of the above onion juice extract to 12 , adjust the pH value of the onion juice extract to 6.5;

[0059] S3 Alcoholic fermentation: use yeast Saccharamyces cerevisiae ATCC9763 as the strain, add 1kg / 10t of active dry yeast to warm water at 35-42°C or an aqueous solution containing 5% sugar, mix well, let stand, and gently stir once every 10 min , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com