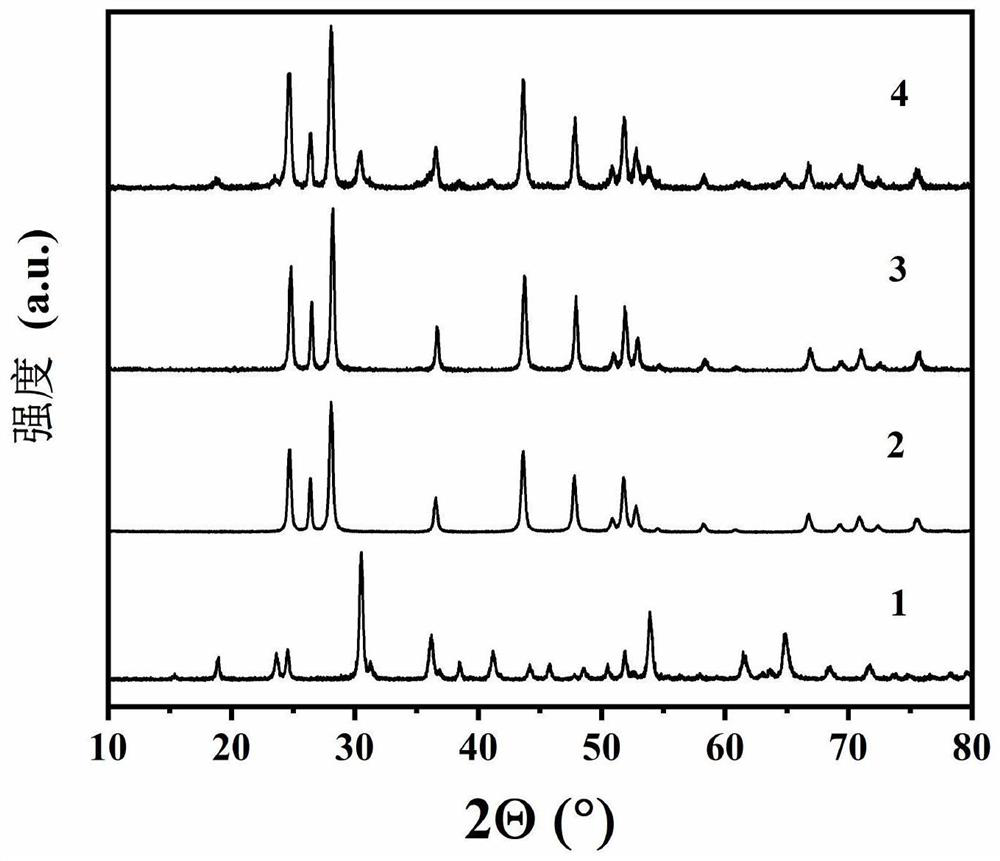

Preparation method of CoWO4-CdS one-dimensional nano composite photocatalyst and application of photocatalyst

A nano-composite, photocatalyst technology, applied in the field of photocatalysis, can solve the problems of fast photo-generated carrier recombination rate, reduce visible light catalytic activity, etc., to achieve the effect of improving photocatalytic water splitting efficiency, promoting separation and transfer, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

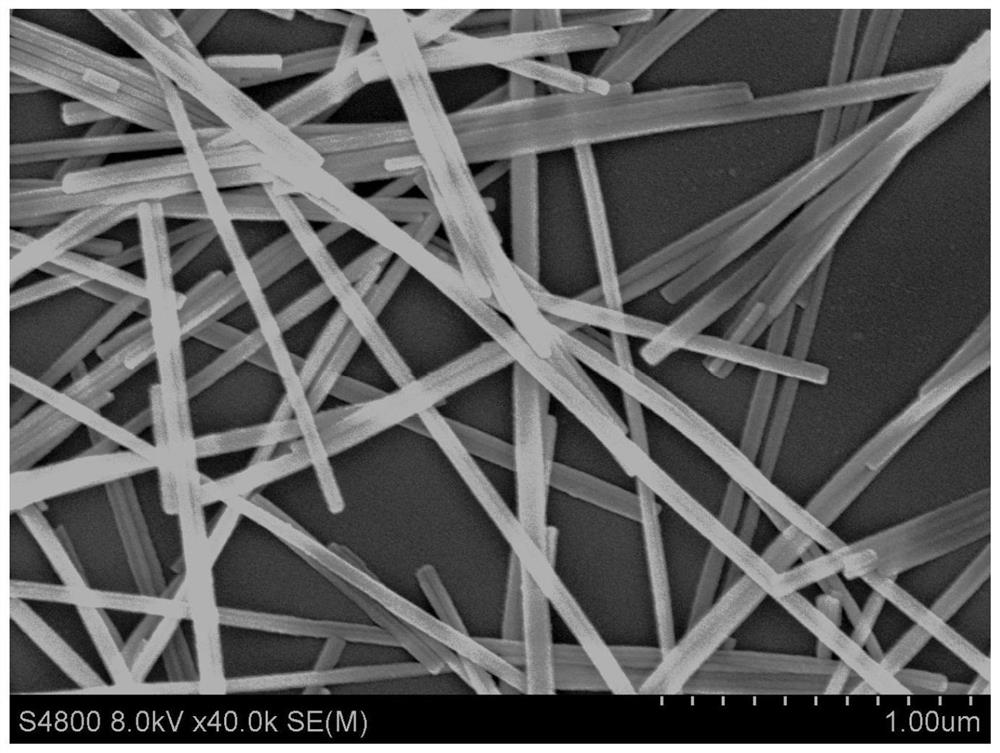

[0026] 1) Weigh 2mmol of cadmium chloride and 4mmol of sodium diethyldithiocarbamate into a 100mL beaker, add 50mL of deionized water, and stir at a speed of 500r / min for 60min to obtain a suspension A.

[0027] 2) The suspension A was separated by centrifugation at a centrifugal speed of 7000r / min, and the separated solid matter was dried in an oven at 60°C to obtain the precursor B.

[0028] 3) Take 1.124g of precursor B, add 40mL of ethylenediamine, stir at a speed of 400r / min for 60min to form a uniform and stable solution, transfer to a 50mL hydrothermal reaction kettle, keep at 180°C for 24h, cool to room temperature, and obtain a suspension Turbid liquid C.

[0029] 4) Separating the cadmium sulfide in the suspension C by suction filtration, washing with water and alcohol for several times, drying the separated solid matter in an oven at 60° C. to obtain cadmium sulfide nanowires.

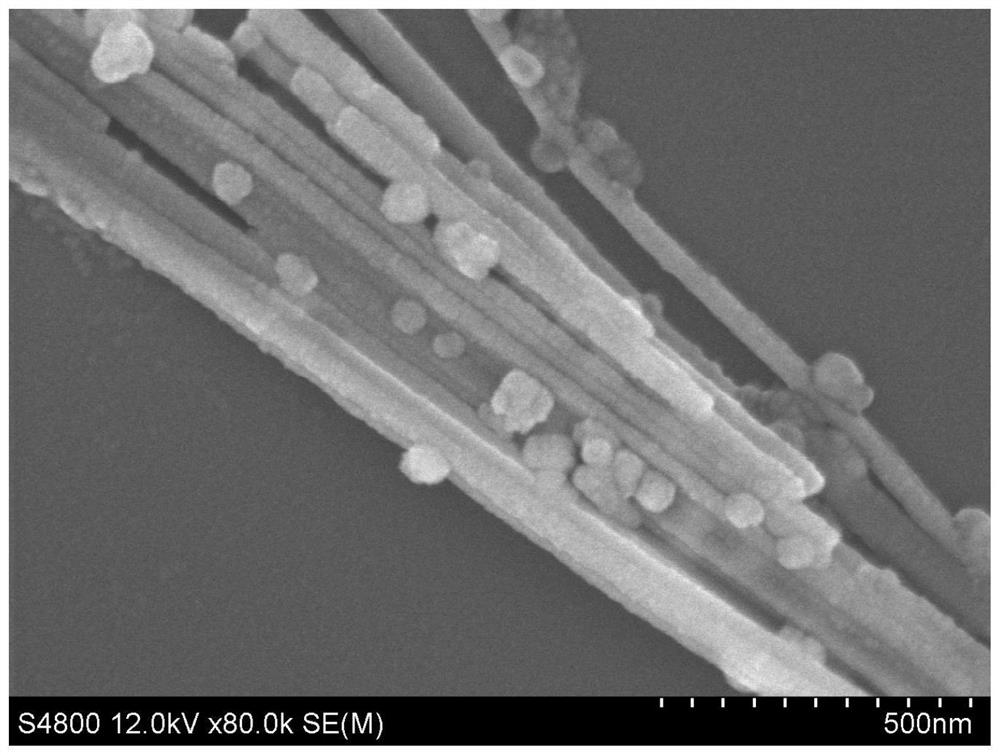

[0030] 5) Weigh 100 mg of cadmium sulfide nanowires, add 40 ml of deionized water, and ...

Embodiment 2

[0035] 1) Weigh 2mmol of cadmium chloride and 4mmol of sodium diethyldithiocarbamate into a 100mL beaker, add 50mL of deionized water, and stir at a speed of 500r / min for 60min to obtain a suspension A.

[0036] 2) The suspension A was separated by centrifugation at a centrifugal speed of 7000r / min, and the separated solid matter was dried in an oven at 60°C to obtain the precursor B.

[0037] 3) Take 1.124g of precursor B, add 40mL of ethylenediamine, stir at a speed of 400r / min for 60min to form a uniform and stable solution, transfer to a 50mL hydrothermal reaction kettle, keep at 180°C for 24h, cool to room temperature, and obtain a suspension Turbid liquid C.

[0038] 4) Separating the cadmium sulfide in the suspension C by suction filtration, washing with water and alcohol for several times, drying the separated solid matter in an oven at 60° C. to obtain cadmium sulfide nanowires.

[0039] 5) Weigh 100 mg of cadmium sulfide nanowires, add 40 ml of deionized water, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com