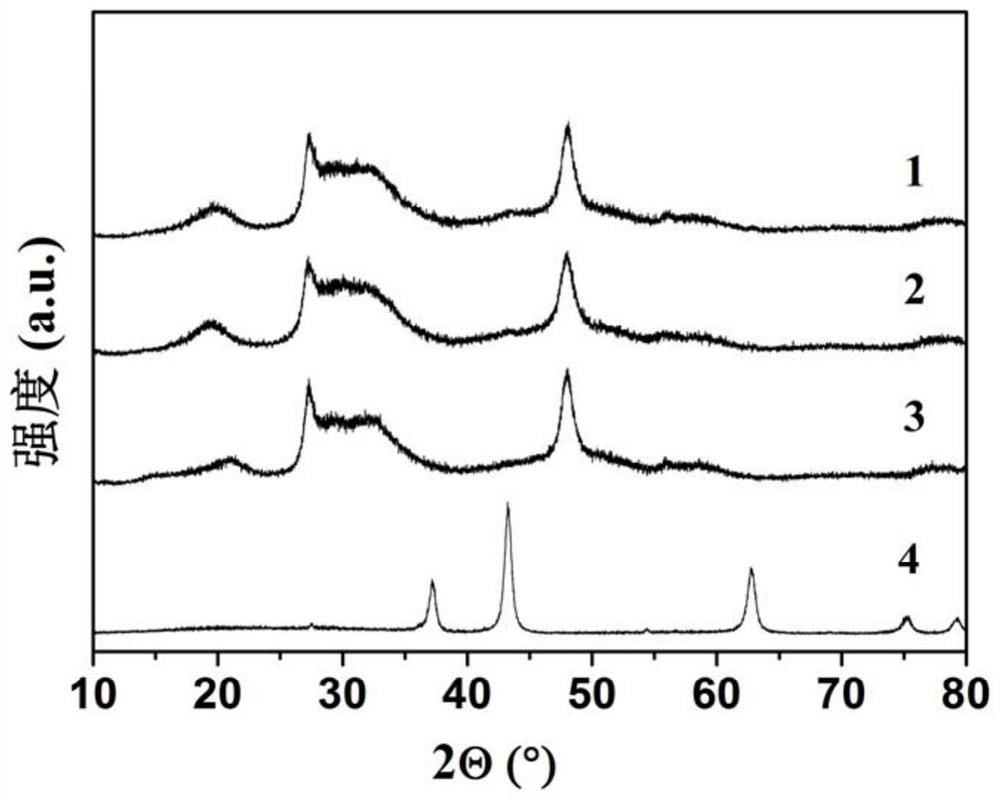

tin-in 2 the s 3 Preparation method and application of nanocomposite photocatalyst

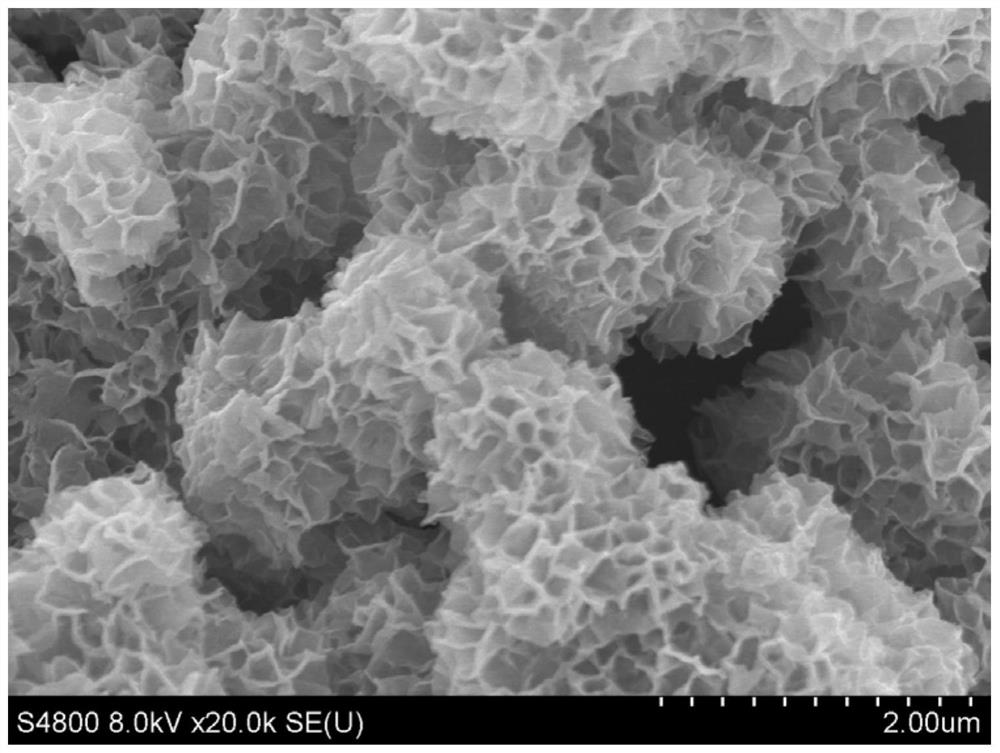

A tin-in2s3, nano-composite technology, applied in the field of photocatalysis, can solve the problems of hydrogen production activity limitation, and achieve the effect of short reaction time, simple equipment and uniform product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh 8.2 mmol of hexadecylamine and add it to 100 mL of absolute ethanol, add 1.6 ml of deionized water with a pipette gun, and stir at 500 r / min for 30 min to obtain solution A.

[0026] 2) Use a pipette gun to pipette 4.45mL of isopropyl titanate into solution A, adjust the rotation speed to 300r / min, stir for 3 minutes to obtain suspension B, and place suspension B in the room for aging for 18 hours.

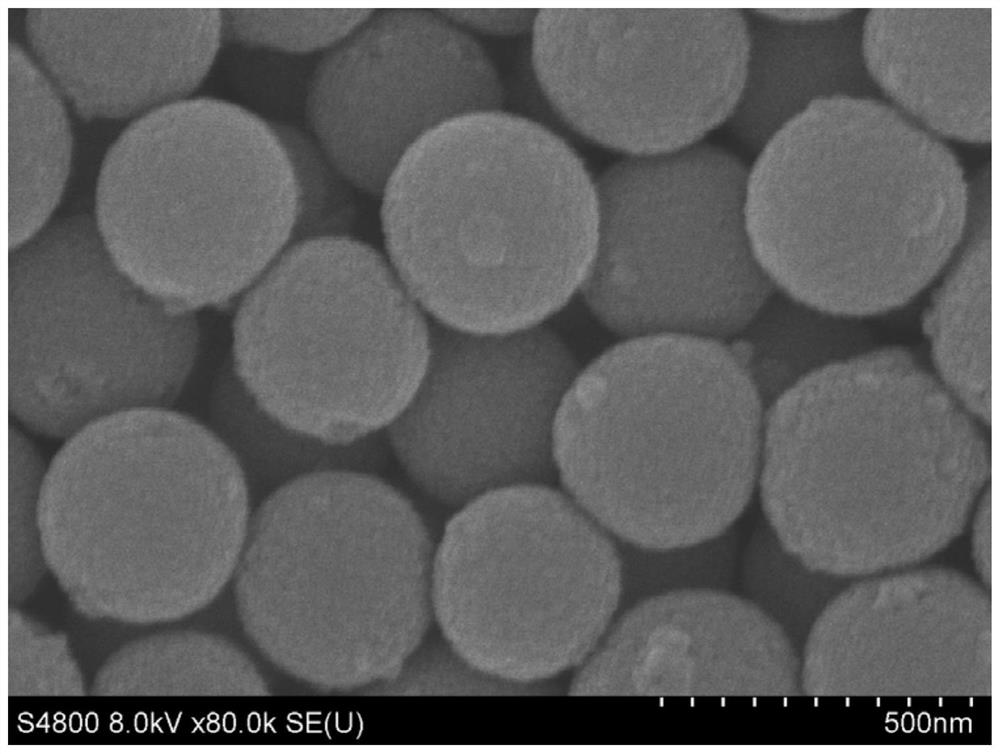

[0027] 3) The titanium dioxide in the suspension B was separated by centrifugation at a centrifugal speed of 7000r / min, and the separated solid matter was dried in an oven at 60°C to obtain titanium dioxide nanospheres.

[0028] 4) Take 100mg of titanium dioxide nanospheres and spread them on a corundum boat of 75×13×9mm, place the corundum boat in a high-temperature tube furnace, in 99.99wt% high-purity ammonia gas (flow rate of 200 standard ml / min) Heating to 700°C in a medium temperature, and keeping it warm for 4 hours, and getting titanium nitride nanospheres ...

Embodiment 2

[0033] 1) Weigh 8.2 mmol of hexadecylamine and add it to 100 mL of absolute ethanol, add 1.6 ml of deionized water with a pipette gun, and stir at 500 r / min for 30 min to obtain solution A.

[0034] 2) Use a pipette gun to pipette 4.45mL of isopropyl titanate into solution A, adjust the rotation speed to 300r / min, stir for 3 minutes to obtain suspension B, and place suspension B in the room for aging for 18 hours.

[0035] 3) The titanium dioxide in the suspension B was separated by centrifugation at a centrifugal speed of 7000r / min, and the separated solid matter was dried in an oven at 60°C to obtain titanium dioxide nanospheres.

[0036] 4) Spread 100mg of titanium dioxide nanospheres on a corundum boat of 75×13×9mm, place the corundum boat in a high-temperature tube furnace, in 99.99% high-purity ammonia gas (flow rate: 200 standard ml / min) Heating to the range of 700° C., keeping it warm for 4 hours, and cooling down with the furnace to obtain titanium nitride nanospheres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com