A photocatalytic water splitting hydrogen production molybdenum doped indium zinc sulfide hollow hierarchical structure photocatalyst and its preparation method

A technology of photocatalyst and hierarchical structure, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems of low quantum efficiency and energy conversion rate, and restrict the practical application pace of hydrogen production by photolysis of water, etc. , to improve migration and separation efficiency, high-efficiency photocatalytic hydrogen production performance, and prolong excited state lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation steps of the present invention are as follows:

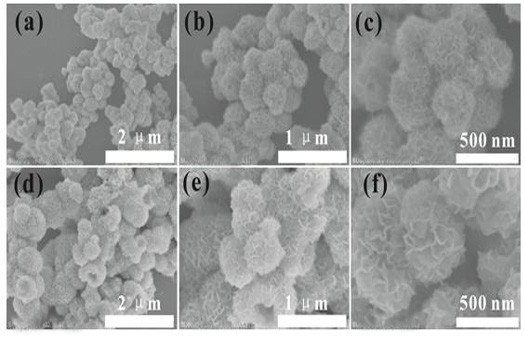

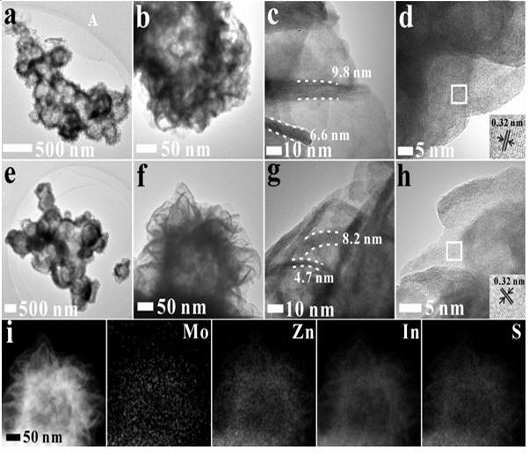

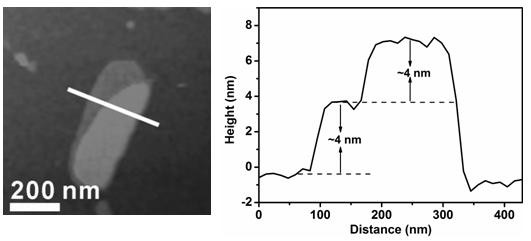

[0029] Dissolve appropriate amount of molybdenum powder in H under ice bath 2 o 2Molybdenum-containing precursor solution was obtained in the solution, and the solution was added dropwise to 20 mL of ethanol solvent, then zinc chloride, indium chloride, and thioacetamide were dissolved in the above ethanol solution in a molar ratio of 1:2:4, and stirred After uniformity, it was transferred to a high-pressure reactor, kept at 120°C for 2 hours, and cooled to room temperature naturally. The obtained product was sequentially washed with deionized water and absolute ethanol, and vacuum-dried to obtain molybdenum-doped ZnIn 2 S 4 Hierarchical structure photocatalyst named M-ZIS.

Embodiment 1

[0031] Dissolve 0.212 mg molybdenum powder in 200 μL H under ice bath 2 o 2 Molybdenum-containing precursor solution was obtained in the solution, and the solution was added dropwise to 20 mL of ethanol solvent, then zinc chloride, indium chloride, and thioacetamide were dissolved in the above ethanol solution in a molar ratio of 1:2:4, and stirred After uniformity, it was transferred to a high-pressure reactor, kept at 120°C for 2 hours, and cooled to room temperature naturally. The obtained product was successively washed with deionized water and absolute ethanol, and vacuum-dried to obtain ZnIn with a molybdenum doping mass of 0.05%. 2 S 4 Hierarchical structured photocatalyst named M 0.05 -ZIS. Then 20 mg of the synthesized powder catalyst was accurately weighed and placed in a photo-splitting water reactor to test the hydrogen production performance of photo-splitting water.

Embodiment 2

[0033] Dissolve 0.423mg molybdenum powder in 200 μL H under ice bath 2 o 2 Molybdenum-containing precursor solution was obtained in the solution, and the solution was added dropwise to 20 mL of ethanol solvent, then zinc chloride, indium chloride, and thioacetamide were dissolved in the above ethanol solution in a molar ratio of 1:2:4, and stirred After uniformity, it was transferred to a high-pressure reactor, kept at 120°C for 2 hours, and naturally cooled to room temperature. The obtained product was washed with deionized water and absolute ethanol in turn, and vacuum-dried to obtain ZnIn with a molybdenum doping mass of 0.1%. 2 S 4 Hierarchical structured photocatalyst named M 0。1 -ZIS. Then 20 mg of the synthesized powder catalyst was accurately weighed and placed in a photo-splitting water reactor to test the hydrogen production performance of photo-splitting water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com