Preparation method of composite antibacterial coating aluminum foil

A composite antibacterial and aluminum foil technology, applied in coatings, devices for coating liquid on surfaces, anti-corrosion coatings, etc., can solve problems such as the increase in the incidence of infectious diseases, and achieve improved hydrophilicity, improved efficiency, and high adsorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

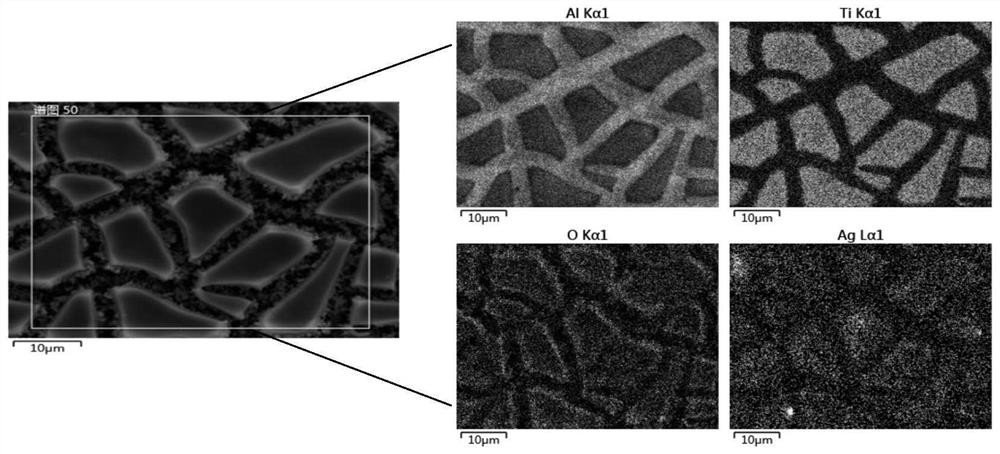

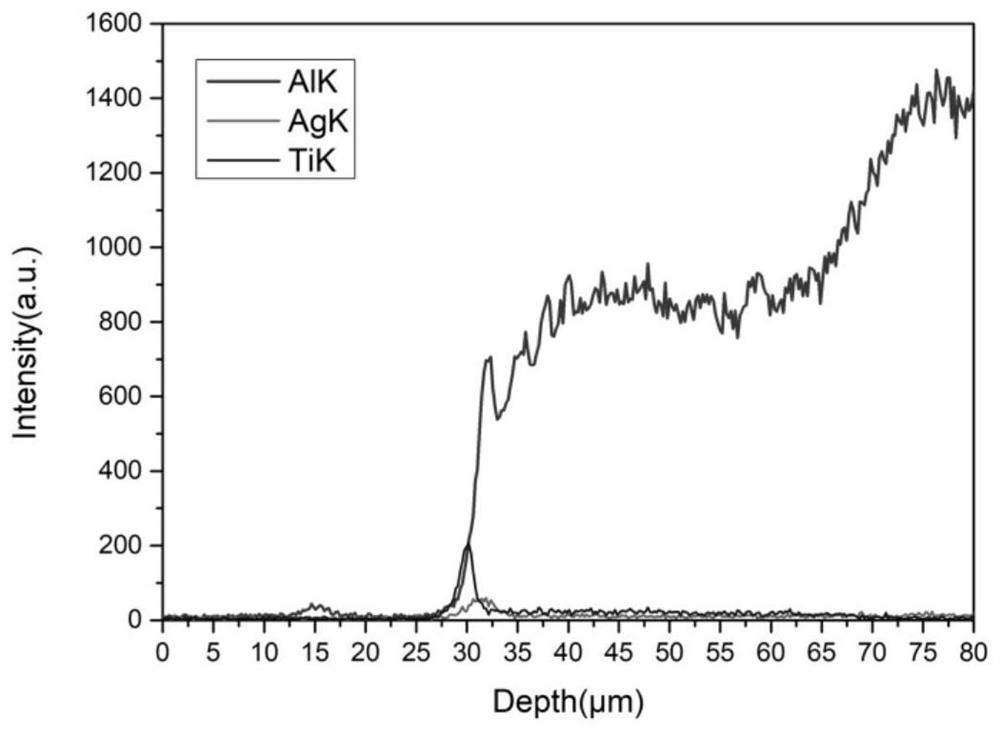

Image

Examples

Embodiment 1

[0031] (1) Take 60ml of absolute ethanol as a solvent, add 7.5ml of butyl titanate as a titanium source, add 3.6ml of glacial acetic acid to control the acidity of the solution, add 0.45g of polyvinylpyrrolidone as a dispersant, and then add 1ml of acetylacetone as a Hydrolysis inhibitor, stirred until a uniform and transparent light yellow A solution was obtained.

[0032] (2) 20ml of ethanol and 3.6ml of deionized water are miscible as a solvent, 0.375g of silver nitrate is added thereto, 0.113g of anhydrous citric acid is added as a stabilizer, and after 0.3ml of nitric acid is added dropwise, stir until transparent and colorless B solution.

[0033] (3) Add solution B dropwise to solution A at a rate of 15 drops per minute with a separatory funnel, and stir for 2 hours to obtain stable TiO 2 / Ag composite sol.

[0034] (4) the obtained TiO in (3) 2 The / Ag composite sol was placed in an ultrasonic environment of 80 Hz for 1.5 h, and then placed for 48 h to age the sol. ...

Embodiment 2

[0038] (1) Take 60ml of absolute ethanol as a solvent, add 9ml of butyl titanate as a titanium source, add 4.5ml of glacial acetic acid to control the acidity of the solution, add 0.18g of polyvinylpyrrolidone as a dispersant, and then add 1.5ml of acetylacetone as a Hydrolysis inhibitor, stirred until a uniform and transparent light yellow A solution was obtained.

[0039] (2) 20ml of ethanol and 4.3ml of deionized water are miscible as a solvent, 0.225g of silver nitrate is added thereto, 0.113g of anhydrous citric acid is added as a stabilizer, and after 0.75ml of nitric acid is added dropwise, stir until transparent and colorless B solution.

[0040] (3) Add solution B dropwise to solution A at a rate of 8 drops per minute with a separatory funnel, and stir for 1 hour to obtain stable TiO 2 / Ag composite sol.

[0041] (4) the obtained TiO in (3) 2 The / Ag composite sol was placed in an ultrasonic environment of 60 Hz for 1 h, and then placed for 72 h to age the sol.

...

Embodiment 3

[0045] (1) Take 60ml of absolute ethanol as a solvent, add 7.5ml of butyl titanate as a titanium source, add 3.6ml of glacial acetic acid to control the acidity of the solution, add 0.45g of polyvinylpyrrolidone as a dispersant, and then add 1ml of acetylacetone as a Hydrolysis inhibitor, stirred until a uniform and transparent light yellow A solution was obtained.

[0046] (2) 20ml of ethanol and 3.6ml of deionized water are miscible as a solvent, 0.375g of silver nitrate is added thereto, 0.113g of anhydrous citric acid is added as a stabilizer, and after 0.3ml of nitric acid is added dropwise, stir until transparent and colorless B solution.

[0047](3) Add solution B dropwise to solution A at a rate of 15 drops per minute with a separatory funnel, and stir for 2 hours to obtain stable TiO 2 / Ag composite sol.

[0048] (4) the obtained TiO in (3) 2 The / Ag composite sol was placed in an ultrasonic environment of 80 Hz for 1.5 h, and then placed for 48 h to age the sol. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com