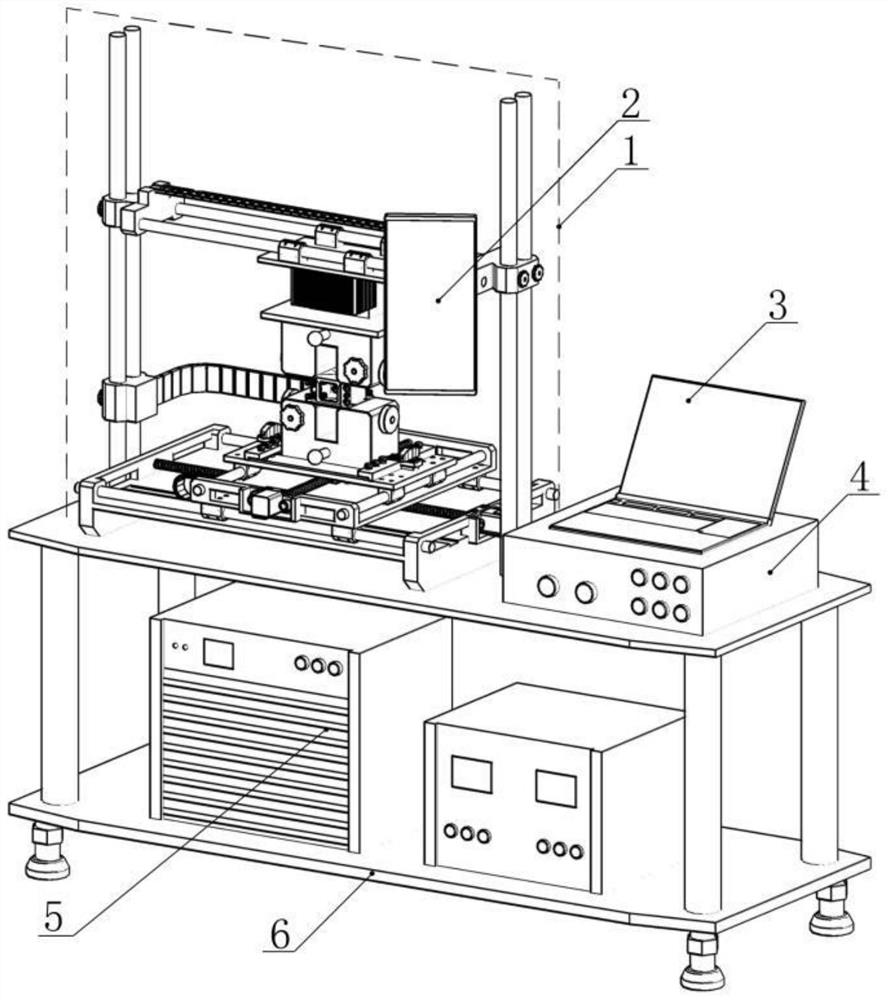

A method and device for machining metal materials based on pulse current

A metal material, pulse current technology, applied in accessories, electric processing equipment, metal processing equipment, etc., can solve the problem of difficult to promote industrialized products of large workpieces, eliminate residual stress and unidirectional coarse columnar crystals, and improve mechanical properties. , the effect of refining the material organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

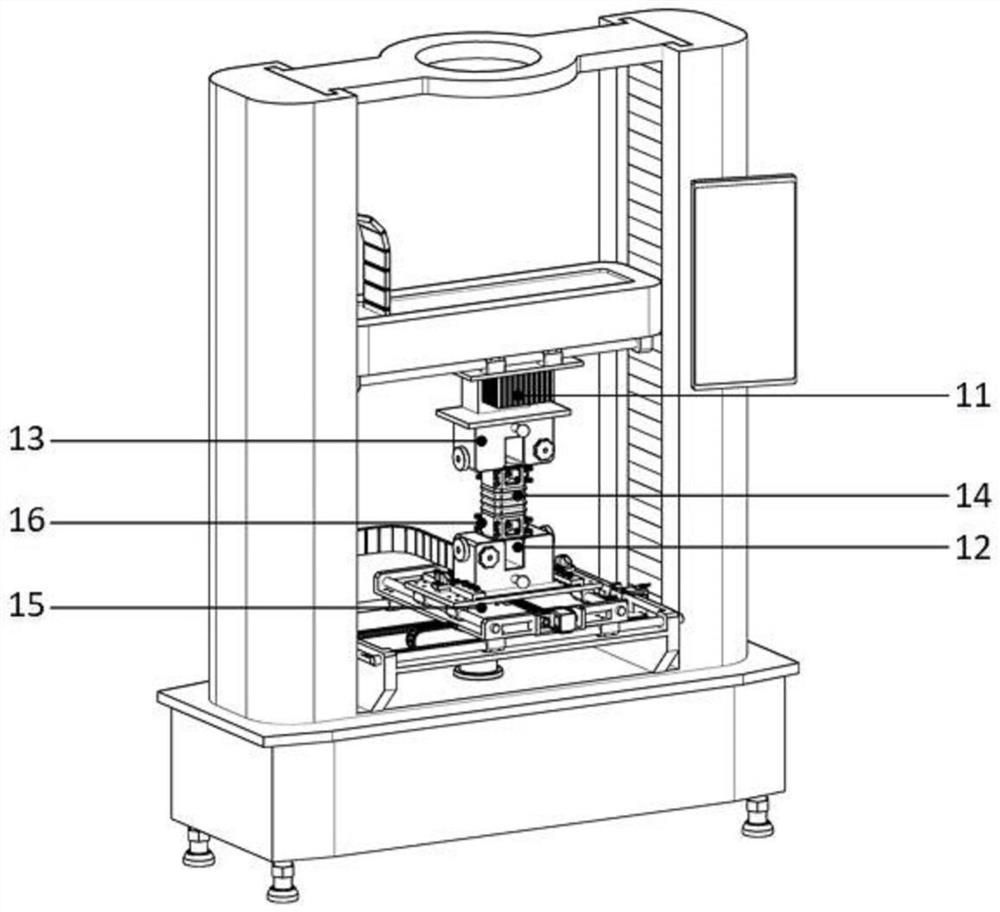

[0041] The 22MnB5 steel material whose length, width and height are respectively 60mm, 10mm and 2mm is ground and polished, and then placed in the atmosphere control system 14, and the ground and polished steel material is kept in close contact with the flat electrode 12 by the clamping system 13, and then the After the atmosphere control system 14 is evacuated, the power supply 5 is turned on to perform pulse current treatment on the ground and polished integral steel material for 180ms. The pulse current treatment parameters are voltage 5V and current density 470MA / m 2 , the frequency is 50Hz, after the pulse current treatment, immediately open the cooling system 16 for water cooling treatment to obtain the steel material strengthened by the pulse current treatment.

[0042] The results show that the performance comparison of the steel material finally obtained in Example 1 and the steel material after traditional heat treatment is shown in Table 1. Compared with the traditio...

Embodiment 2

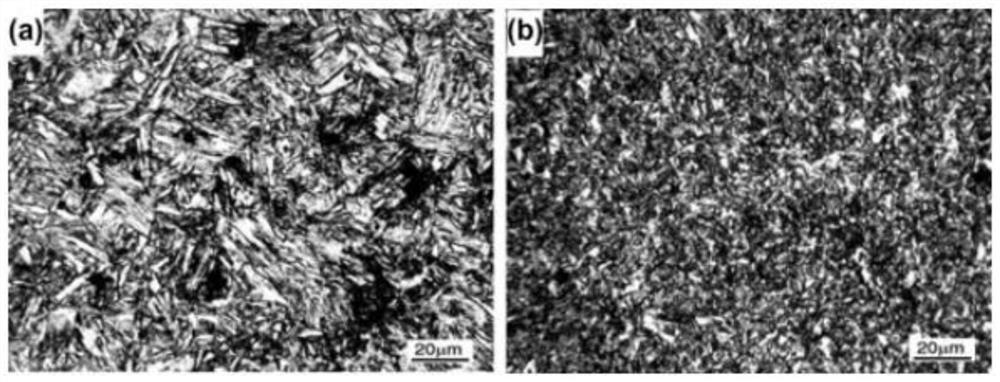

[0046] The TC4 titanium alloy material whose length, width and height are respectively 65mm, 12mm and 2.5mm is ground and polished and placed in the atmosphere control system 14, and then the grinding and polishing titanium alloy material is kept in close contact with the planar electrode 12 by the clamping system 13. , and then the atmosphere control system 14 is evacuated, and the power supply 5 is turned on to perform pulse current treatment on the polished titanium alloy material for 460ms. The pulse current treatment parameters are voltage 5V and current density 60MA / m 2 , frequency 50Hz, after the pulse current treatment, immediately open the cooling system 16 for water cooling treatment to obtain the titanium alloy material strengthened by pulse current treatment. Table 2 shows the performance changes of TC4 titanium alloy materials treated by different processes. Figure 5 Microstructures of TC4 alloys treated with different processes: Figure 5 5a is the TC4 titanium...

Embodiment 3

[0050] The 40Cr steel material with the length, width and height of 68mm, 15mm and 3mm is ground and polished, and then placed in the atmosphere control system 14, and then the grinding and polishing steel material is kept in close contact with the flat electrode 12 by the clamping system 13, and then the After the atmosphere control system 14 is evacuated, the power supply 5 is turned on to perform pulse current treatment for 480ms on the ground and polished integral steel material. The pulse current treatment parameters are voltage 5V and current density 300MA / m 2 , the frequency is 50Hz, after the pulse current treatment, immediately open the cooling system 16 for water cooling treatment to obtain the treated 40Cr steel material.

[0051] In the rapid cooling of the 40Cr steel material used in Example 3, due to the large temperature gradient, high residual stress will be generated, which will have more adverse effects on the material structure and performance; after the 40Cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com