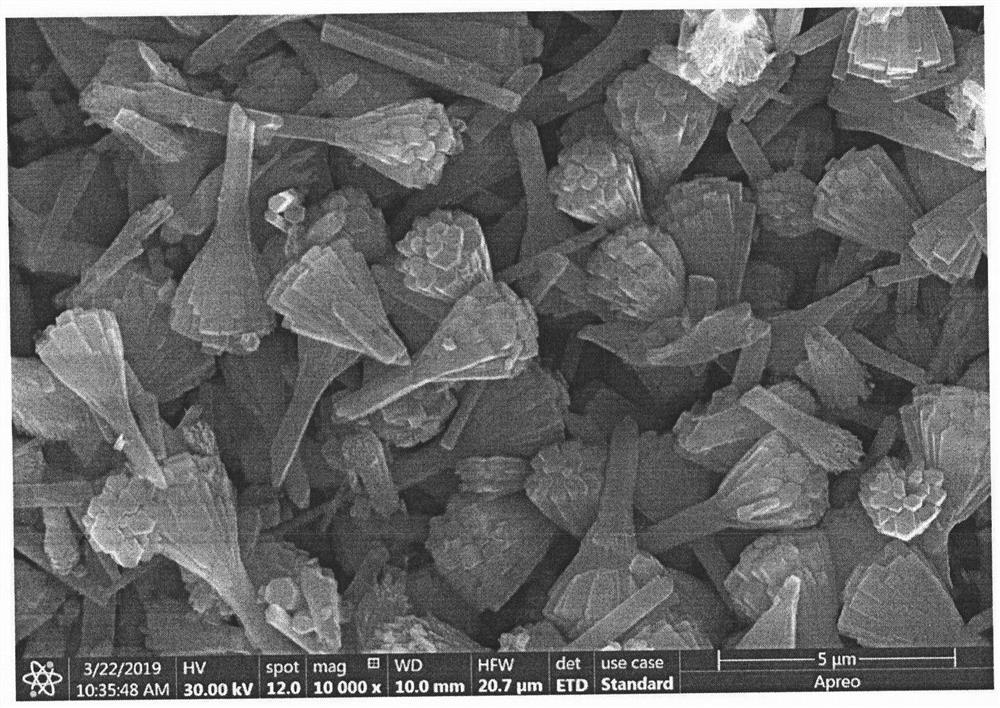

A kind of brush-shaped nano zinc oxide and its preparation method and application

A nano-zinc oxide and brush-like technology, which is applied in the field of functional material preparation, can solve the problems that brush-like nano-zinc oxide has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of brush-shaped nano-zinc oxide, comprising the following steps:

[0026] Mixing inorganic alkali, urea, bacterial cellulose slurry and water to obtain a first mixed solution, and smashing the first mixed solution after freezing into a block to obtain a mashed product;

[0027] The mashed product is mixed with a soluble zinc salt aqueous solution to obtain a second mixed solution; the second mixed solution is subjected to a hydrothermal reaction to obtain the brush-shaped nano-zinc oxide.

[0028] In the present invention, inorganic alkali, urea, bacterial cellulose slurry and water are mixed to obtain a first mixed solution, and the first mixed solution is frozen into a block and then smashed to obtain a mashed product.

[0029] In the present invention, the inorganic base is preferably sodium hydroxide or lithium hydroxide, more preferably sodium hydroxide; the solid content of the bacterial cellulose slurry is preferably 0....

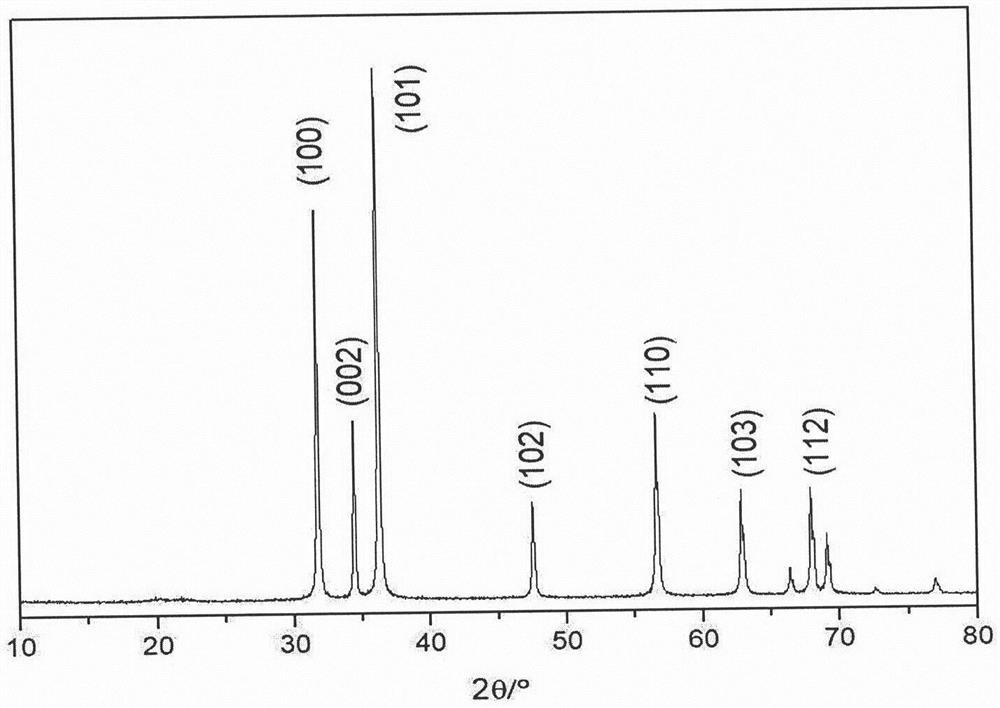

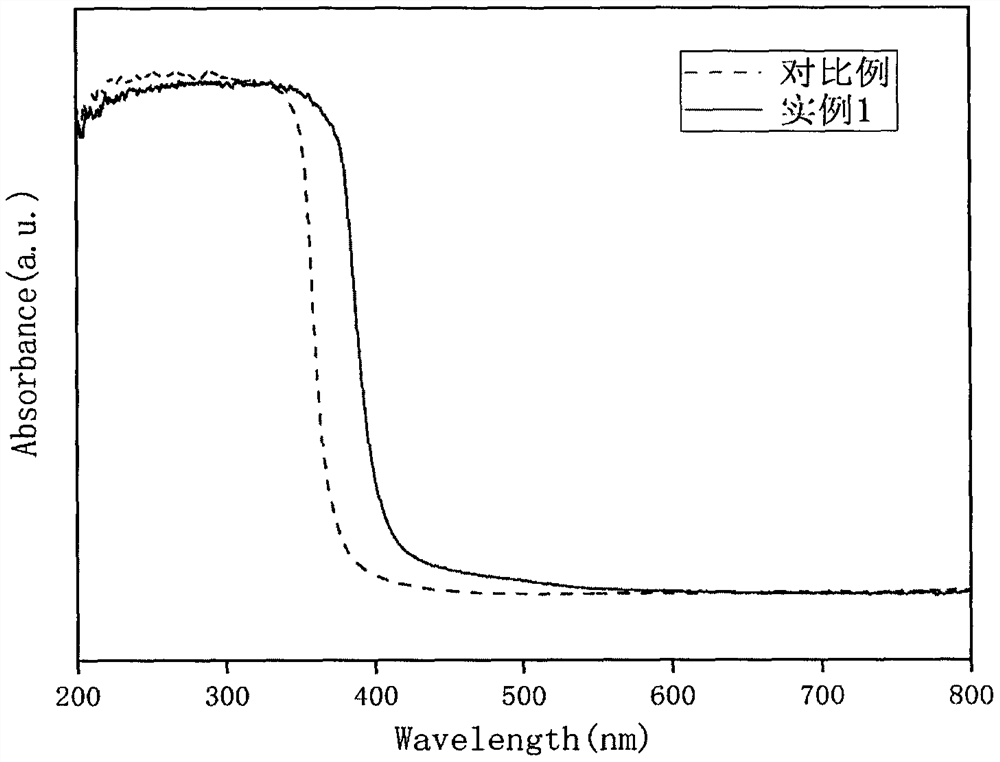

example 1

[0044] Weigh 4.8g of sodium hydroxide and 2.4g of urea and dissolve in 30mL of distilled water, add 30mL of 0.394% bacterial cellulose slurry with a solid content, stir to obtain a first mixed solution, put the first mixed solution in a refrigerator -20 ℃ freeze into a block, and then take it out and mash it to get a mashed product;

[0045] Weigh 2.4g of zinc sulfate heptahydrate, dissolve in 20mL of distilled water to obtain an aqueous solution of zinc sulfate; add the mashed material to the aqueous solution of zinc sulfate, with magnetic stirring simultaneously, to obtain a second mixed solution; the second mixed solution is It was transferred into a 100 mL reaction kettle, and the reaction kettle was placed in a drying box and heated to 150 °C for 3 hours. After the reaction, the obtained reaction solution was suction filtered, and the obtained filter residue was washed with distilled water for many times and placed in a constant temperature drying box at 70 °C. drying to ...

example 2

[0049] Weigh 14.4.g of sodium hydroxide, 7.3g of urea and dissolve in 60mL of distilled water, add 120mL of 0.394% bacterial cellulose slurry with a solid content, stir to obtain a first mixed solution, put the first mixed solution in a refrigerator- Freeze it at 20°C into a block, take it out and mash it to get a mashed product;

[0050] Weigh 7g of zinc sulfate heptahydrate, dissolve it in 60mL of distilled water, and obtain an aqueous solution of zinc sulfate; The gained mash is added to the aqueous solution of zinc sulfate, accompanied by magnetic stirring simultaneously, to obtain a second mixed solution; The second mixed solution is moved into In a 300mL reaction kettle, the reaction kettle was placed in a drying box and heated to 140 °C for 3 hours. After the reaction was completed, the reaction solution was suction filtered, and the obtained filter residue was washed with distilled water for many times, and then placed in a constant temperature drying box at 80 °C to dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com