Refrigerating device and method for preparing high-strength-and-toughness layered porous titanium alloy material through refrigerating device

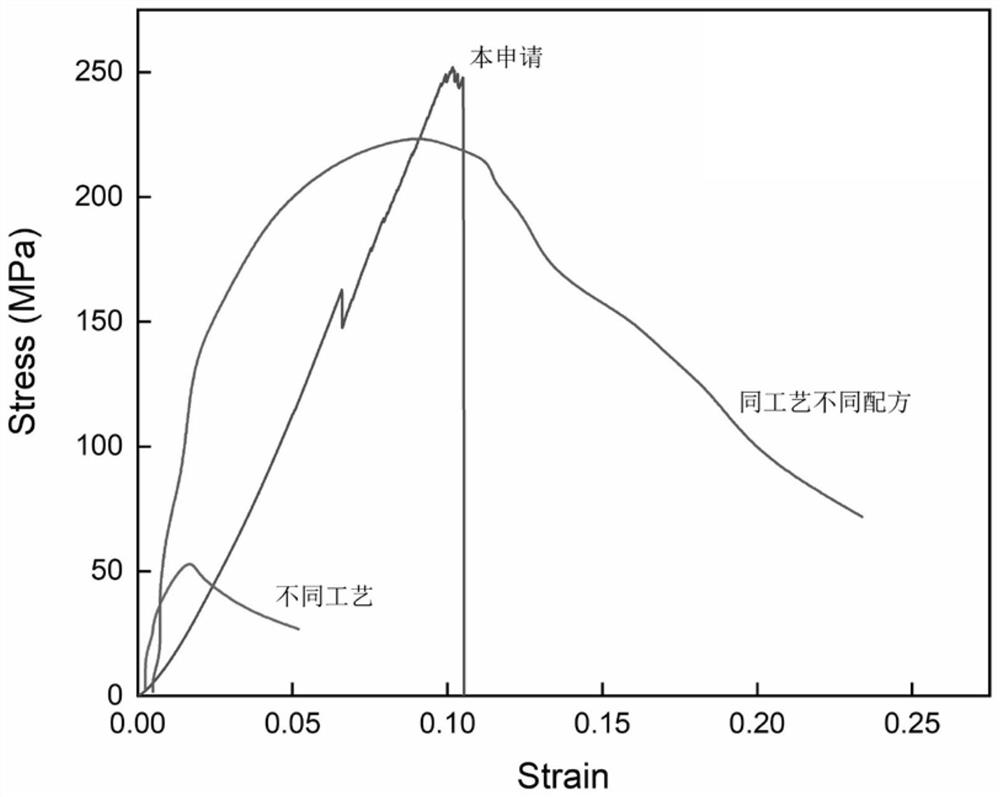

A freezing device and high-strength technology, applied in the field of materials, can solve problems such as inability to remove, plastic toughness decline, etc., and achieve the effects of controllable cooling temperature, large pore size selectivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

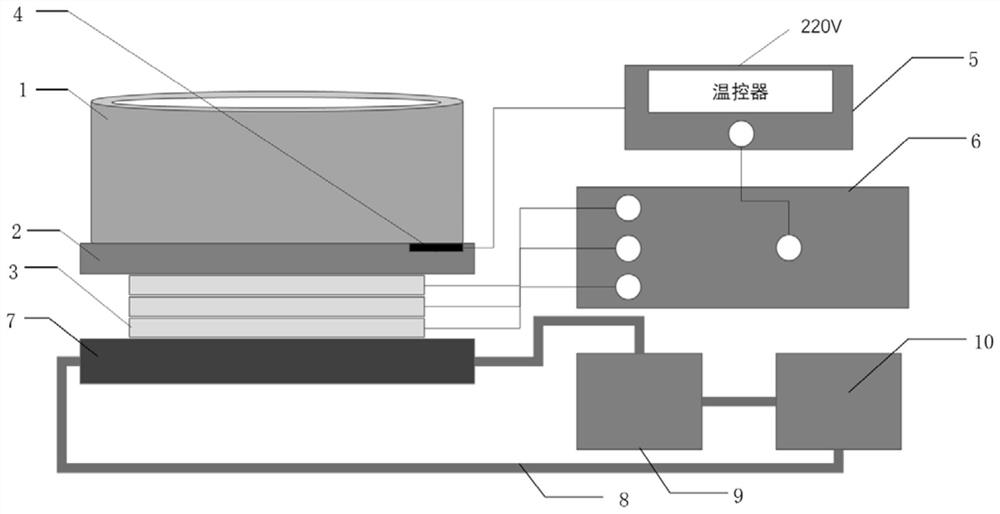

[0028] Such as figure 1 As shown, the present embodiment provides a freezing device, including a mold 1, a metal sheet 2, a semiconductor refrigeration sheet group 3, a heat-sensitive semiconductor 4, a temperature controller 5, a power supply 6, a metal hollow plate 7, a cooling pipeline 8, a cooling Liquid storage unit 9 and cooling and power unit 10 .

[0029] The mold 1 is a frame body with a circle of closed side walls, without a bottom surface penetrating up and down, and can be in any shape such as a ring.

[0030]The mold 1 is placed on the thin metal sheet 2, and the thin metal sheet 2 is fixed on the semiconductor refrigeration sheet group 3. Wherein, the mold 1 can be pasted on the metal sheet 2 by sealing grease, so as to avoid slurry leakage, and it is sufficient to separate the mold 1 from the metal sheet 2 when demoulding.

[0031] The semiconductor refrigerating sheet group 3 is connected to the power supply 6, and the power supply 6 supplies power to the sem...

Embodiment 2

[0039] This embodiment provides a method for preparing a high-strength and tough layered porous titanium alloy material, comprising the following steps:

[0040] Step 1: Prepare the bonding thickener, powder and deionized water into a mixed slurry. Among them, the bonding thickener includes Sanxian gum and polyvinyl alcohol, and the powder includes TiH 2 , B 4 C. Low melting point liquid transmission medium. The low-melting point liquid transmission medium is a low-melting point metal (such as Al, Ni) or a low-melting point glass additive (such as Al 2 o 3 -SiO 2 ). Low melting point means that it is alloyed with other powders to form a low melting point mixed slurry, which reduces the sintering temperature.

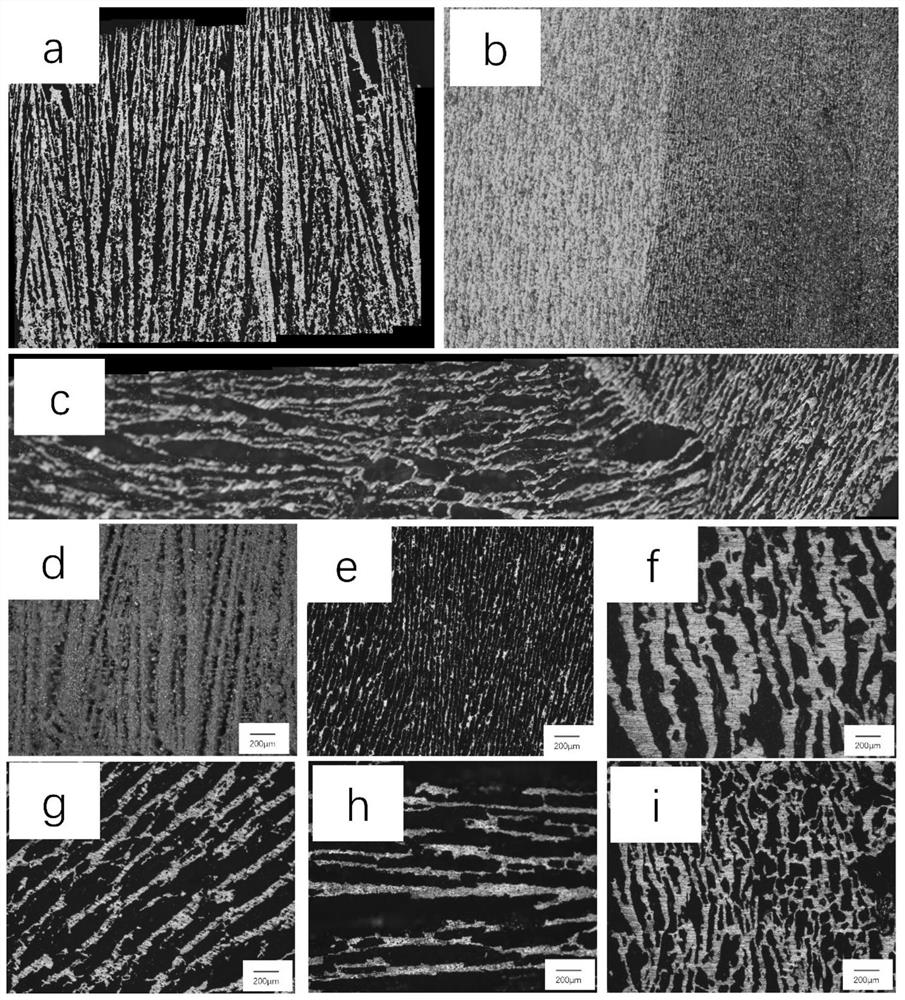

[0041] Specifically, a sanxian gum solution in which the sanxian gum accounts for 0.4% (vol%) of deionized water is prepared. Mix TiH2, B4C and Al evenly and add it into the Sanxian gum solution, wherein, TiH 2 , B 4 The mass ratio of C and Al is 100:1.5:6, the ...

Embodiment 3

[0048] This embodiment provides a method for preparing a high-strength and tough layered porous titanium alloy material, comprising the following steps:

[0049] Step 1. Specifically, prepare a sanxian gum solution with a deionized water content of 0.1% (vol%). TiH 2 , B 4 After C, Al are mixed evenly, add in the Sanxian glue solution, wherein, TiH 2 , B 4 The mass ratio of C and Al is 100:1.5:6, the particle size is 1 μm, and the volume of the powder accounts for 30% of the volume of the mixed slurry. At the same time, polyvinyl alcohol with a mass of 1% of the total mass of the powder was added, uniformly mixed by ball milling, the balls were zirconia balls, and ball milling was carried out for 8 hours. De-bubble.

[0050] Step 2. Specifically, place the PTFE mold of the freezing device in Example 1 on the copper sheet, slowly pour the slurry, adjust the cooling rate to 10°C / min, and the cooling temperature to -30°C, and freeze until the surface is completely frozen . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com