Flexible battery electrode and manufacturing process thereof

A flexible battery and electrode technology, used in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve the problem of weak electrode connection, achieve long-term stable charge and discharge, excellent electrochemical performance, and achieve the effect of charge and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

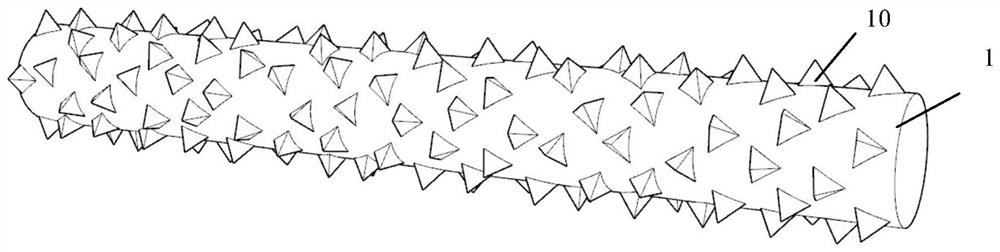

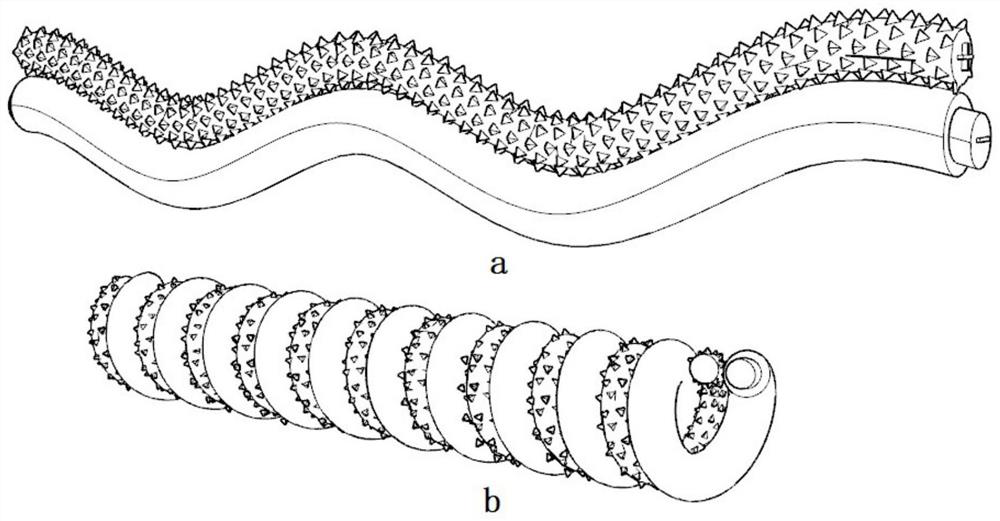

[0048] combine Figure 1-Figure 3 , the present invention provides a method for preparing a flexible battery electrode, using an etching method to etch and prepare an irregular raised structure 100 on the surface of the positive electrode, including the following steps:

[0049] S1 Preparation of positive electrode

[0050] 1. The active material, conductive agent, and binder are made according to a certain formula, and then extruded and dried to form a positive electrode 1;

[0051] 2. Place it in acid solution or alkali solution for 10 seconds to 120 seconds according to the type and nature of the material;

[0052] 3. Rinse with distilled water several times;

[0053] 4. Then rinse with electrolyte solution for 1~3 times;

[0054] 5. Dry at 30℃~150℃ for 24 hours.

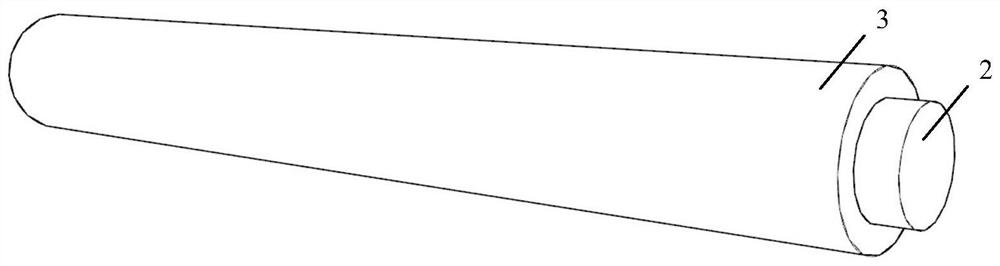

[0055] S2 preparation of negative electrode

[0056]1. Active materials, conductive agents, and binders are prepared according to a certain formula, then extruded and dried to form the negative electrode 2; ...

Embodiment 1

[0075] A preparation method of zinc-manganese flexible fibrous battery, comprising the following steps:

[0076] 1. Prepare the positive electrode material: the positive electrode uses manganese dioxide as the active material, graphene as the conductive agent, and polytetrafluoroethylene as the binder. The specific ratio is: manganese dioxide 30 wt%, graphene 20 wt%, polytetrafluoroethylene Vinyl fluoride 50 wt%. Taking 100mg of positive electrode material as an example, it contains 30mg of manganese dioxide, 20mg of graphene, and 50mg of polytetrafluoroethylene.

[0077] 2. Dry grinding: Add the above materials into the mortar and stir for 600s, and mix them evenly.

[0078] 3. Wet grinding: Add N-methylpyrrolidone solvent to the above-mentioned ground materials, add 2ml of N-methylpyrrolidone solvent per 100mg of powder, and stir until viscous.

[0079] 4. Extrusion: Inject the wet-milled material into the syringe and extrude it at a constant speed.

[0080] 5. Drying: Pl...

Embodiment 2

[0096] A preparation method for a lithium-ion flexible fibrous battery, comprising the following steps:

[0097] 1. Prepare the positive electrode material: the positive electrode uses lithium iron phosphate as the active material, carbon nanotubes as the conductive agent, and polytetrafluoroethylene as the binder. The ratio is: lithium iron phosphate 30%, carbon nanotubes 10wt%, polytetrafluoroethylene Vinyl fluoride 60 wt%. Taking 100mg of positive electrode material as an example, it contains 30mg of lithium iron phosphate, 10mg of carbon nanotubes, and 60mg of polytetrafluoroethylene.

[0098] 2. Dry grinding: Add the above materials into the mortar and stir for 600s, and mix them evenly.

[0099] 3. Wet grinding: Add N-methylpyrrolidone solvent to the above-mentioned ground materials, add 2.4ml N-methylpyrrolidone solvent per 100mg of powder, and stir until viscous.

[0100] 4. Extrusion: Inject the wet-milled material into the syringe and extrude it at a constant speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com