A quick-drying sports towel

A quick-drying and moving technology, applied in physical treatment, cellulose plastic material layered products, liquid-repellent fibers, etc., can solve the problem that chemical fiber raw materials cannot be biodegraded, natural fiber towels cannot absorb moisture and dry quickly, and the environment Unfriendliness and other issues, to achieve excellent moisture absorption and perspiration effects, good quick-drying, and good cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

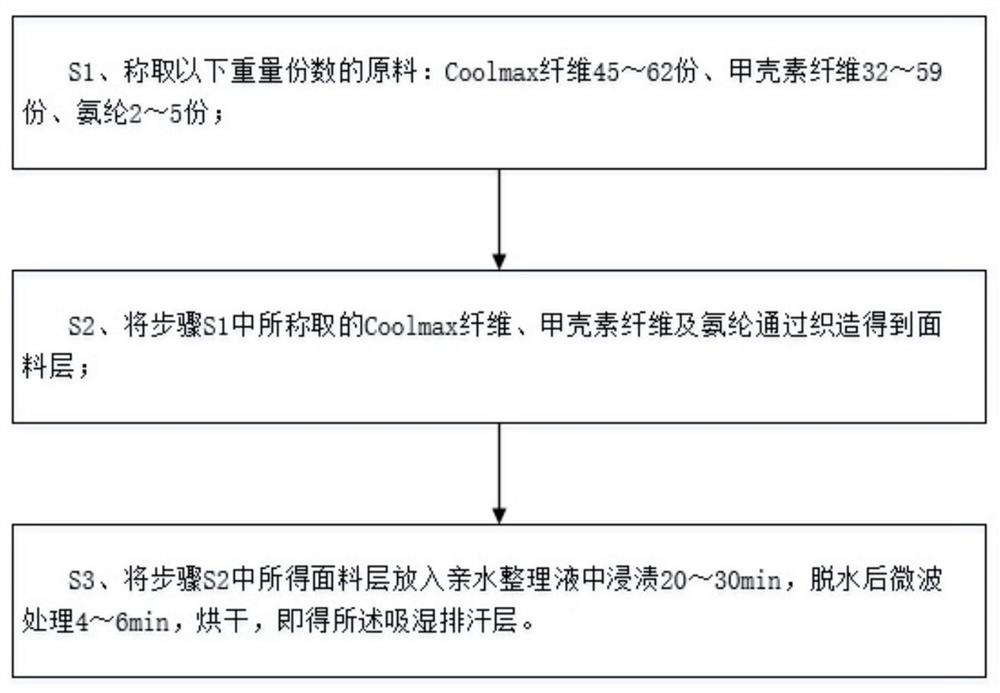

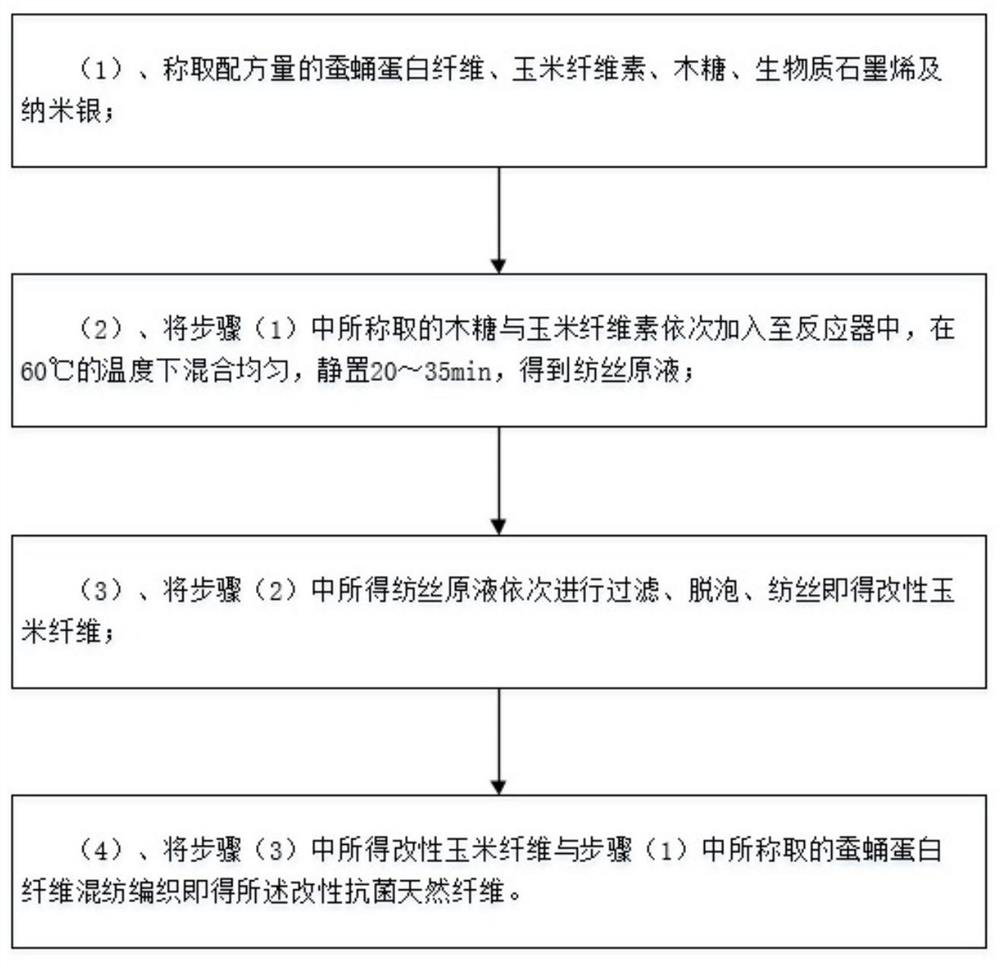

[0038] refer to image 3 As shown, a modified antibacterial natural fiber is made of the following raw materials: 45 g of silkworm chrysalis protein fiber, 100 g of corn cellulose, 2 g of xylose, 0.1 g of biomass graphene, and 0.02 g of nano silver.

[0039] The preparation method of above-mentioned modified antibacterial natural fiber comprises the following steps:

[0040] (1), take by weighing the silkworm chrysalis protein fiber, corn cellulose, xylose, biomass graphene and nano silver of formula amount;

[0041] (2), the xylose, corn cellulose, biomass graphene and nano silver that are weighed in the step (1) are added to the reactor successively, at a temperature of 60 ℃, mix uniformly, leave standstill for 21min, obtain spinning silk stock solution;

[0042] (3), the obtained spinning stock solution in step (2) is successively filtered, defoamed, and spun to obtain modified corn fiber;

[0043] (4), the modified corn fiber obtained in the step (3) and the silkworm chry...

Embodiment 2

[0045] refer to image 3 As shown, a modified antibacterial natural fiber is made from the following raw materials: 89 g of silkworm pupa protein fiber, 100 g of corn cellulose, 8.3 g of xylose, 5 g of biomass graphene, and 0.15 g of nano silver.

[0046] The preparation method of above-mentioned modified antibacterial natural fiber comprises the following steps:

[0047] (1), take by weighing the silkworm chrysalis protein fiber, corn cellulose, xylose, biomass graphene and nano silver of formula amount;

[0048] (2), the xylose, corn cellulose, biomass graphene and nano silver that are weighed in the step (1) are added into the reactor successively, at a temperature of 60 ℃, mix homogeneously, leave standstill for 35min, obtain spinning silk stock solution;

[0049] (3), the obtained spinning stock solution in step (2) is successively filtered, defoamed, and spun to obtain modified corn fiber;

[0050] (4), the modified corn fiber obtained in the step (3) and the silkworm...

Embodiment 3

[0052] refer to image 3 As shown, a modified antibacterial natural fiber is made from the following raw materials: 85g of silkworm chrysalis protein fiber, 100g of corn cellulose, 3g of xylose, 1.4g of biomass graphene, and 0.08g of nano silver.

[0053] The preparation method of above-mentioned modified antibacterial natural fiber comprises the following steps:

[0054] (1), take by weighing the silkworm chrysalis protein fiber, corn cellulose, xylose, biomass graphene and nano silver of formula amount;

[0055] (2), add the xylose, corn cellulose, biomass graphene and nano silver that are weighed in the step (1) into the reactor successively, mix at a temperature of 60 ℃, leave standstill for 20~35min, to obtain spinning dope;

[0056] (3), the obtained spinning stock solution in step (2) is successively filtered, defoamed, and spun to obtain modified corn fiber;

[0057] (4), the modified corn fiber obtained in the step (3) and the silkworm chrysalis protein fiber weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com