Dust-removing and sulfur-removing device for chemical high-temperature waste gas

A high-temperature waste gas and chemical technology, applied in chemical instruments and methods, gaseous effluent wastewater treatment, water/sludge/sewage treatment, etc., can solve problems such as high energy consumption of desulfurization devices, health impact, and inability to treat waste gas. Achieve the effects of increasing desulfurization efficiency, increasing contact time, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

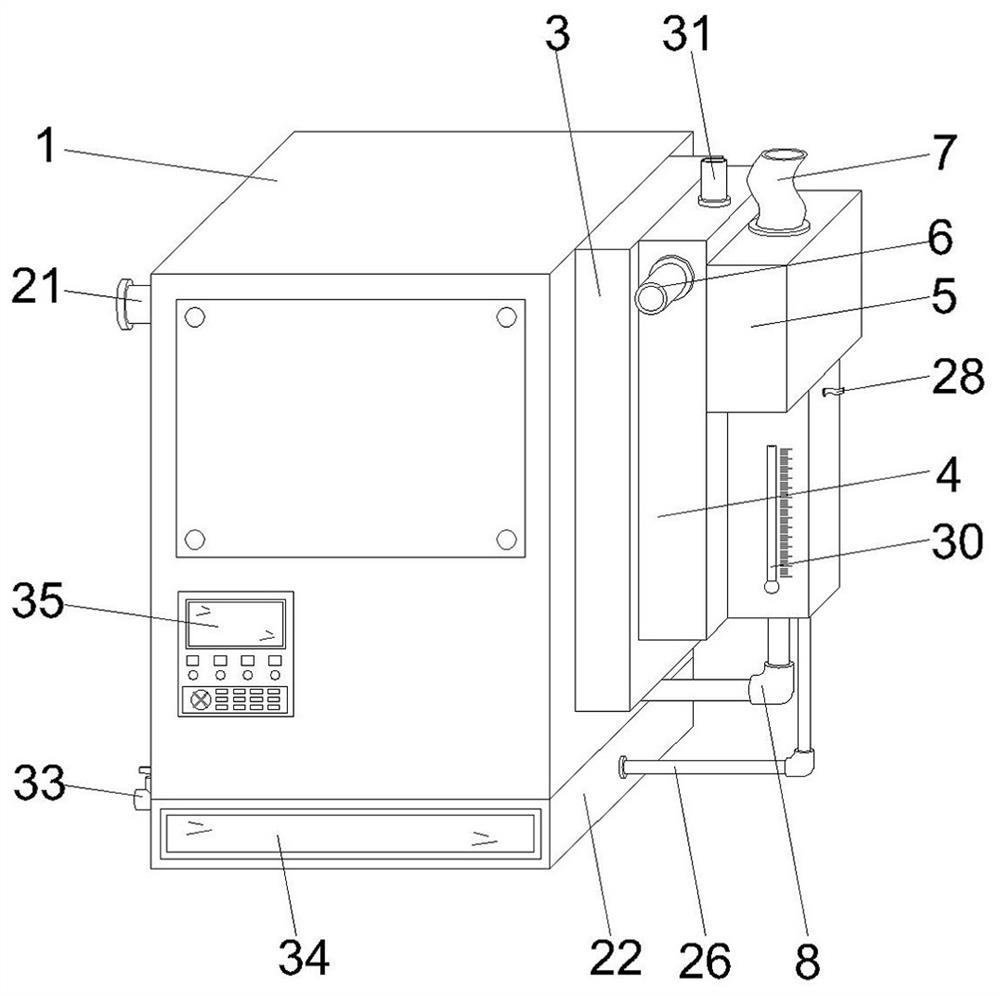

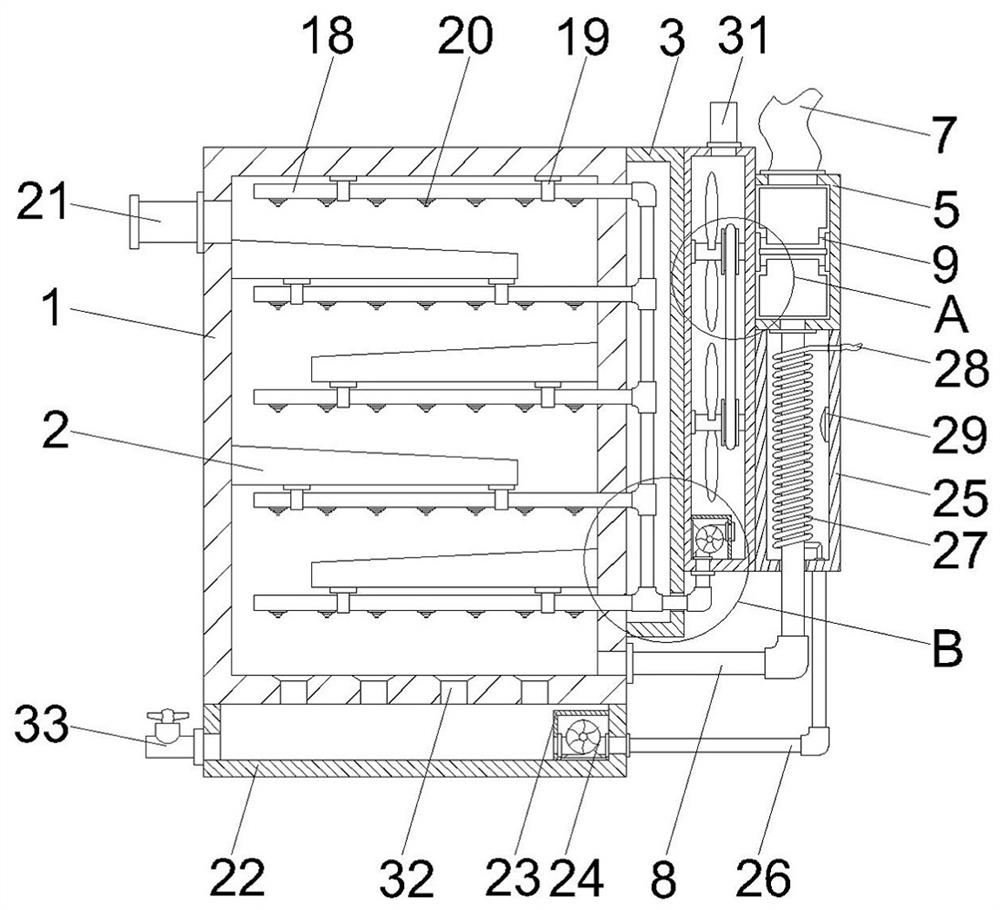

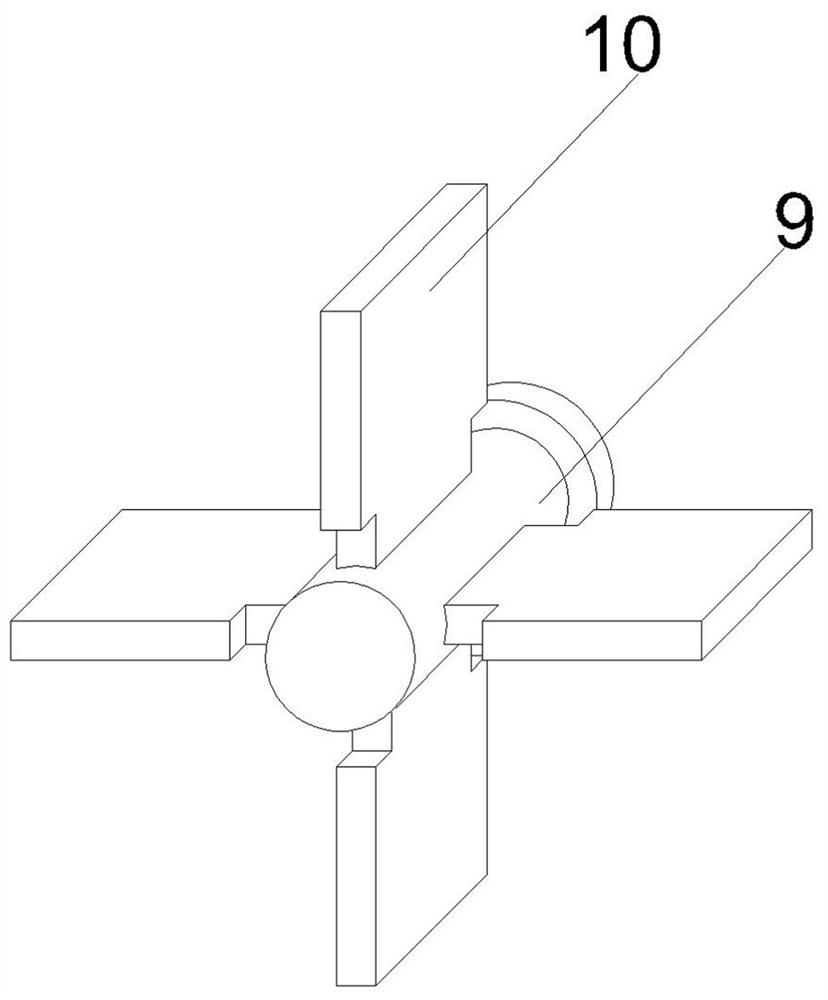

[0022] see Figure 1 to Figure 5 , the present invention provides a technical solution: a chemical high-temperature waste gas dedusting and desulfurization device, including a desulfurization treatment box 1, and inner guide plates 2 are installed on both sides corresponding to the inside of the desulfurization treatment box 1, and one side of the desulfurization treatment box 1 The side pipe installation box 3 is fixedly installed, and the side of the side pipe installation box 3 away from the inner guide plate 2 is fixedly installed with a side stirring water tank 4, and the side of the side stirring water tank 4 away from the side pipe installation box 3 is fixedly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap