Preparation method of single crystal type high-nickel ternary layered positive electrode material

A positive electrode material and ternary material technology, which is applied in the field of preparation of high-nickel ternary positive electrode materials, can solve problems such as high temperature flatulence, affecting electrochemical performance, and poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

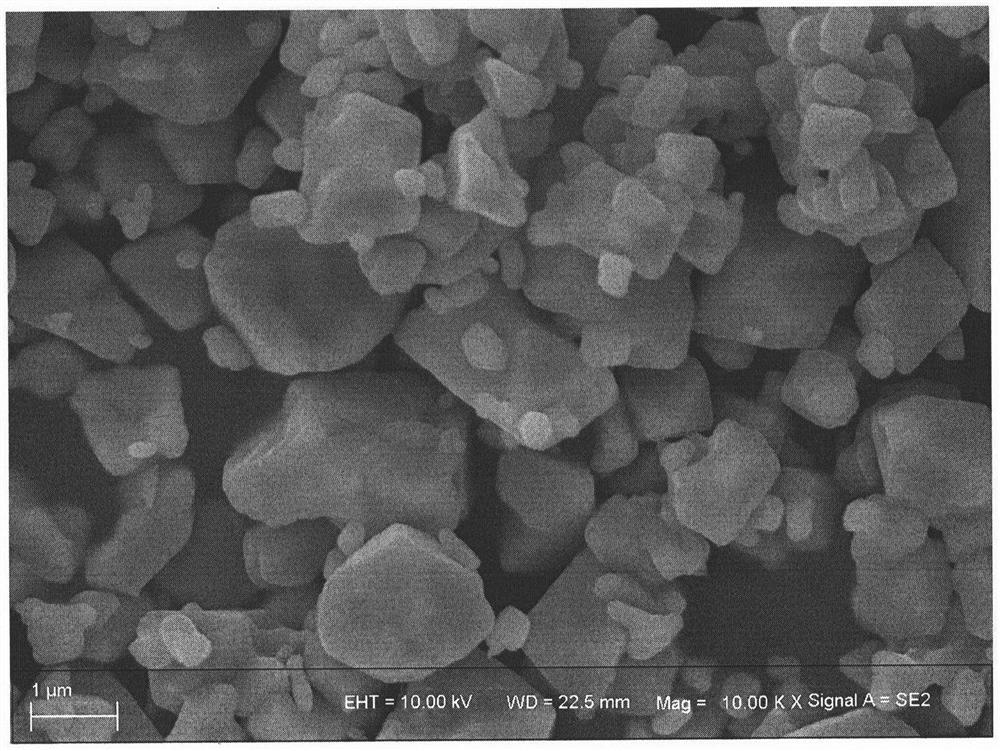

[0024] The single crystal structure ternary cathode material LiNi was prepared according to the following steps 0 8 co 0.1 mn 0.1 o 2 .

[0025] 1) 2.41g Co 3 o 4 , 1.45g LiOH·H 2 O and 9.10 g KNO 3 Grind and mix well to obtain mixture A. Put the above mixture A in an alumina crucible, pre-fire it in a muffle furnace at 500°C for 5h, then raise the temperature to 750°C and keep it for 15h, then cool to room temperature, and the obtained product is deionized After washing with water for several times, suction filtration, and drying at 120 °C for 24 h, single crystal LiCoO was obtained 2 matrix.

[0026] 2) Weigh 57.04g NiCl 2 ·6H 2 O, 5.94 g MnCl 2 4H 2 O and 11.33g LiOH·H 2 O, with the above 2.94g LiCoO 2 The matrix was ground and mixed evenly to obtain mixture B.

[0027] 3) Press the above mixture B into tablets, the pressure is 20MPa, the tableting time is 2min, put into a crucible and calcined in a tube furnace under an oxygen atmosphere, pre-calcined at 500...

Embodiment 2

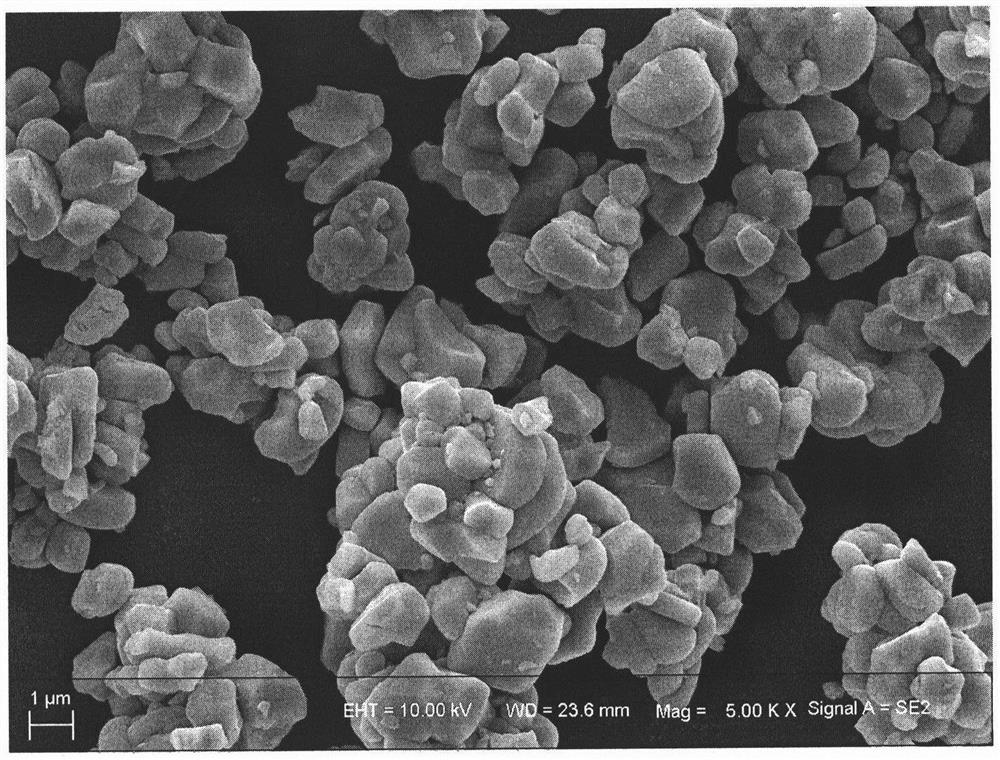

[0030] The single crystal structure ternary cathode material LiNi was prepared according to the following steps 0 6 co 0.2 mn 0.2 o 2 .

[0031] 1) Weigh 2.41g Co 3 o 4 , 1.45g LiOH·H 2O and 5.26g NaCl were thoroughly ground and mixed uniformly to obtain mixture A, which was placed in an alumina crucible, pre-fired in a muffle furnace at 500°C for 5h, then raised to 850°C for 15h, then cooled to room temperature, and The obtained product was washed several times with deionized water, filtered with suction, and dried at 120 °C for 24 h to obtain single crystal LiCoO 2 matrix.

[0032] 2) Weigh 23.65g NiSO 4 ·6H 2 O, 5.07g MnSO 4 ·H 2 O and 4.43g Li 2 CO 3 , with the above 2.94gLiCoO 2 The matrix is ground and mixed evenly.

[0033] 3) Press the above mixture into tablets with a pressure of 20 MPa and a tablet pressing time of 2 minutes, put it into a crucible and calcinate it in an oxygen atmosphere in a tube furnace, pre-calcine at 650°C for 5 hours, then rais...

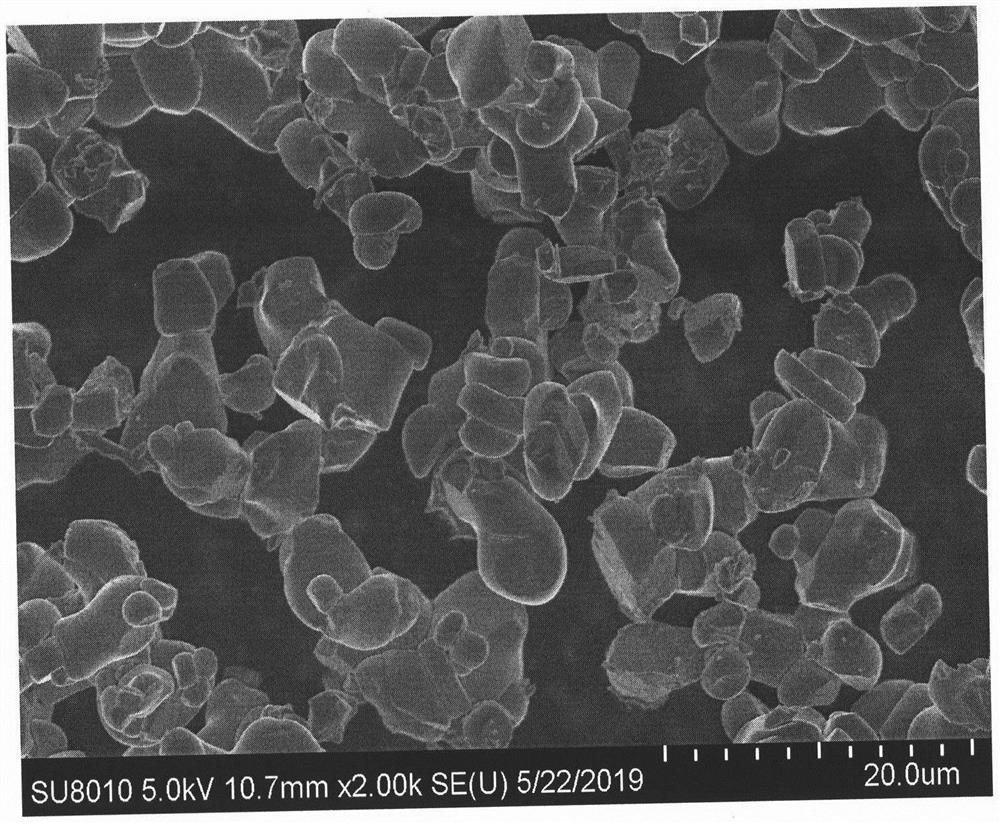

Embodiment 3

[0036] The single crystal structure ternary cathode material LiNi was prepared according to the following steps 0 5 co 0.2 mn 0.3 o 2 .

[0037] 1) 2.41g Co 3 o 4 , 1.45g LiOH·H 2 O and 6.71g KCl were thoroughly ground and mixed uniformly to obtain mixture A, which was placed in an alumina crucible, pre-fired in a muffle furnace at 500°C for 5h, then raised to 800°C for 15h, then cooled to room temperature, and The obtained product was washed several times with deionized water, filtered with suction, and dried at 120 °C for 24 h to obtain single crystal LiCoO 2 matrix.

[0038] 2) Weigh 21.81g Ni(NO 3 ) 2 ·6H 2 O, 11.30g Mn(NO 3 ) 2 4H 2 O and 4.43g Li 2 CO 3 , with the above 2.94g LiCoO 2 The matrix was ground and mixed evenly to obtain mixture B.

[0039] 3) Press the above mixture B into tablets with a pressure of 20 MPa and a tablet pressing time of 2 minutes, put it into a crucible and calcinate it in an oxygen atmosphere in a tube furnace, pre-calcine at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com