Expandable microsphere containing chemical foaming agent and preparation method thereof

A technology of chemical foaming agent and expanded microspheres, which is applied in the field of expandable microspheres containing chemical foaming agents and its preparation, can solve problems such as difficult to accurately control the initiation temperature, and achieve the goal of expanding application methods and application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

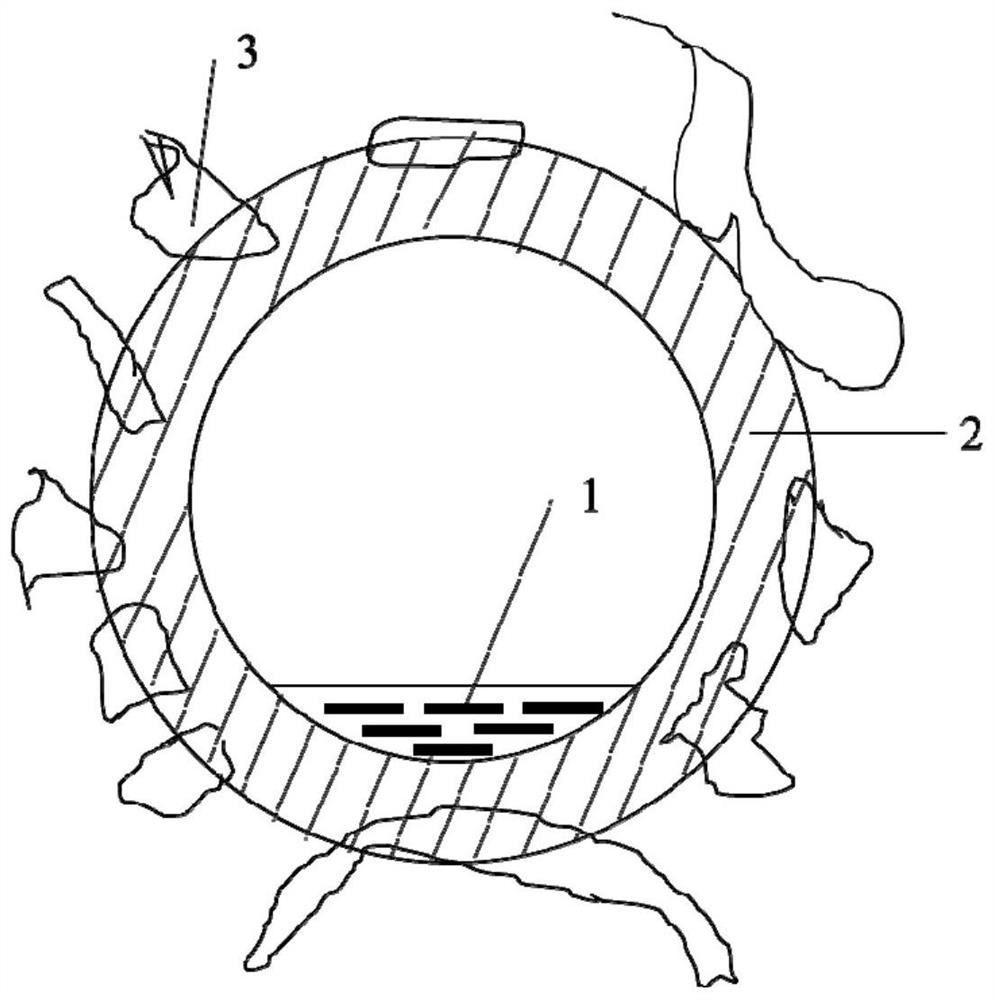

Image

Examples

Embodiment 1

[0048] S1. prepare 1kg of magnesium sulfate solution of 0.15mol / L, prepare 1kg of sodium hydroxide solution of 0.6mol / L, then under vigorous stirring, magnesium sulfate is added dropwise in the sodium hydroxide solution, after dropping, pH is 9. Add 0.05% surfactant sodium dodecylbenzenesulfonate and continue to stir for 0.5h to obtain the alkaline aqueous phase of magnesium hydroxide;

[0049] S2. Take 1000 parts of the magnesium hydroxide alkaline aqueous phase prepared by the present invention as the water phase, 60 parts of acrylonitrile, 30 parts of methyl methacrylate, 10 parts of methyl acrylate, 1 part of azobisisoheptanonitrile, diethylene 0.5 part of benzene, 0.05 part of isobutane, 1 part of chemical foaming agent azobisisobutyronitrile (decomposition temperature 98-110°C), mix well to obtain an oil phase, the polymerization temperature is 45°C, the polymerization time is 20h, and then according to this The inventive method for preparing expandable microspheres can ...

Embodiment 2

[0051] S1. In 2 kg of deionized water, add 400 g of silica sol, 0.05% surfactant sodium dibutylnaphthalene sulfonate, adjust the pH to 4 with HCl solution, and then vigorously stir for 0.5 h to obtain the acidic silica sol aqueous phase;

[0052] S2. Take 1000 parts of the silica sol water phase prepared by the present invention as the water phase, 60 parts of acrylonitrile, 30 parts of methyl methacrylate, 10 parts of methyl acrylate, 1 part of azobisisoheptanonitrile, 0.5 part of divinylbenzene, 0.05 part of isobutane, 1 part of chemical foaming agent azobisisobutyronitrile (decomposition temperature 98-110°C), mix uniformly to obtain an oil phase, the polymerization temperature is 45°C, the polymerization time is 20h, and then expandable according to the present invention The preparation method of microspheres prepares expandable microspheres containing chemical blowing agent azobisisobutyronitrile. Microsphere particle size is 16um, T s =105°C, T max = 136°C.

[0053] S...

Embodiment 3

[0061] S1. prepare 1kg of magnesium sulfate solution of 0.15mol / L, prepare 1kg of sodium hydroxide solution of 0.6mol / L, then under vigorous stirring, magnesium sulfate is added dropwise in the sodium hydroxide solution, after dropping, pH is 9. Add 0.05% surfactant sodium dodecylbenzenesulfonate and continue to stir for 0.5h to obtain the alkaline aqueous phase of magnesium hydroxide;

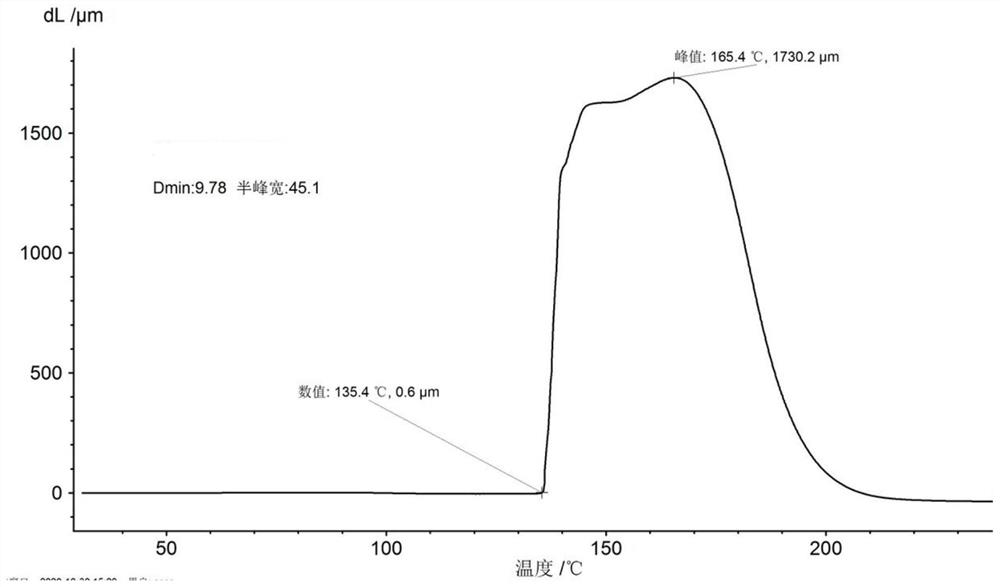

[0062] S2. Take 1000 parts of the magnesium hydroxide alkaline aqueous phase prepared by the present invention as the water phase, 60 parts of acrylonitrile, 30 parts of methyl methacrylate, 10 parts of methacrylic acid, 1 part of azobisisoheptanonitrile, diethylene 0.5 parts of benzene, 0.05 parts of isopentane, 1 part of chemical foaming agent 4,4-oxybisbenzenesulfonyl hydrazide (decomposition temperature 140-160°C), mix well to obtain an oil phase, the polymerization temperature is 45°C, and the polymerization time is 20h , and then according to the preparation method of the expandable micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com