Preparation method and application of carboxylated graphene/chitosan composite coating agent

A technology of carboxylated graphene and chitosan, which is applied in the direction of chitin polysaccharide coating, application, coating, etc., can solve the problem of no adsorption effect of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of carboxylated graphene / chitosan composite finishing agent, comprises the steps:

[0035] Step 1: prepare carboxylated graphene powder

[0036] Add 1 part of graphene oxide to 1000 parts of deionized water, ultrasonically disperse for 60 minutes, then add 10 parts of sodium hydroxide, ultrasonically disperse for 30 minutes, then add 20 parts of α-bromoacetic acid, ultrasonically disperse for 30 minutes, and finally adjust the reaction temperature To 30°C, react for 6 hours to obtain carboxylated graphene dispersion, wash the obtained product with acetic acid and deionized water alternately for 6 times, and finally wash with absolute ethanol for 3 times, and dry the product in vacuum to obtain carboxylated graphene olefin powder;

[0037] Step 2: prepare chitosan solution

[0038] 5 parts of acetic acid are dissolved in 100 parts of deionized water, then 2.5 parts of chitosan are added to adjust the pH value of the solution to 3.5 to obtai...

Embodiment 2

[0044] A kind of finished leather, comprising applying the carboxylated graphene / chitosan composite finishing agent to the tanning finishing section, adjusting the solid content of the carboxylated graphene / chitosan finishing agent to 5%, adopting the finishing method of spraying, coating The coating amount is 20g / sf2; the finishing operation process is as follows: semi-finished leather to be coated → spraying the upper layer of finishing agent → ironing → standing → oscillating and softening → ironing → finished leather, wherein the ironing temperature is 130 ° C, the pressure It is 30kgf, and the strength of vibration pulling is 6.

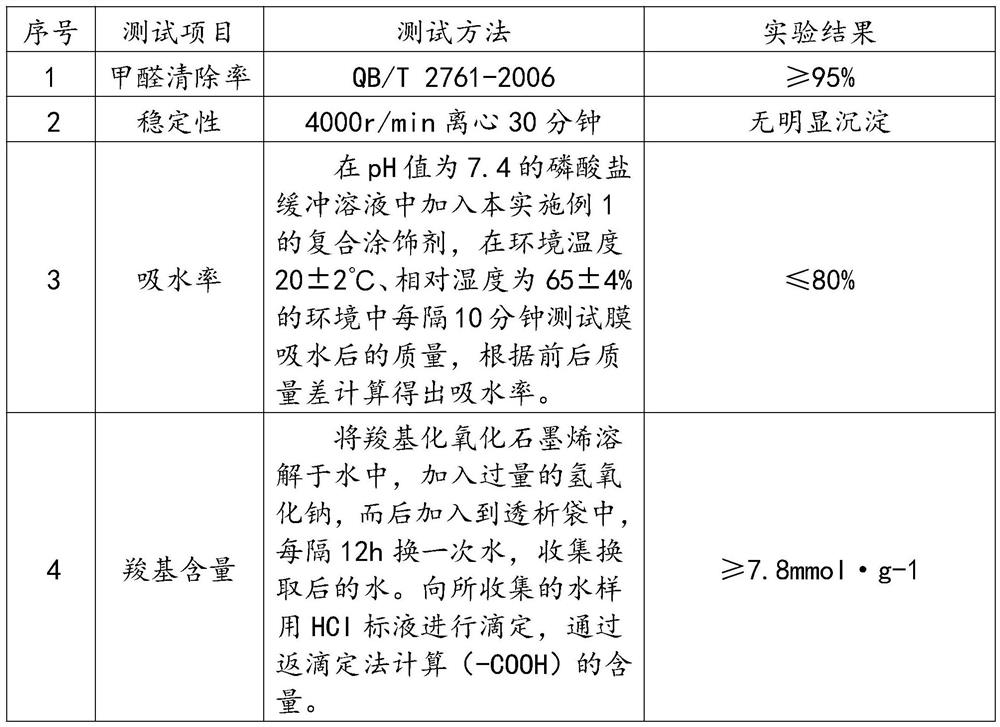

[0045] The finished product that present embodiment 1 obtains obtains experimental data as shown in table 1 through experimental testing, and the finished leather that embodiment 2 obtains obtains experimental data as shown in table 2 through experimental testing:

[0046]

[0047] Table 1

[0048]

[0049] Table 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com