Preparation method of carbon-aluminum composite material

An aluminum composite material and waste technology, which is applied in the field of carbon-aluminum composite material preparation, can solve the problems of destroying production and living safety, affecting environmental sanitation, endangering human health, etc., so as to improve energy gas yield, reduce tar yield, energy The effect of increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

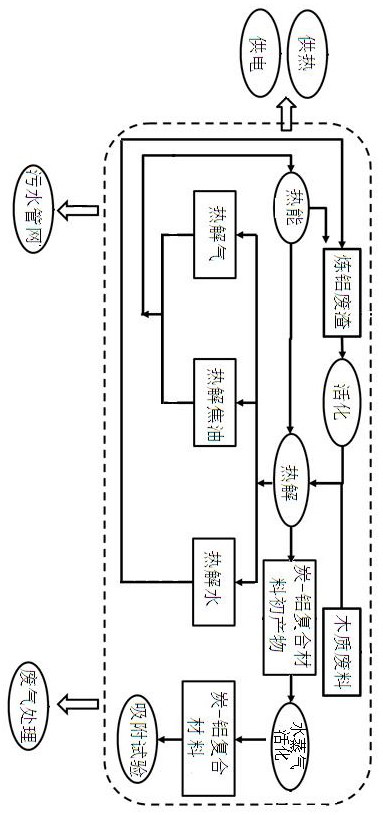

[0024] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0025] Such as figure 1 One example shown is:

[0026] Step (1): Carry out organic acid-heat activation treatment on aluminum smelting waste residue; take equal volume of aluminum smelting waste slag and organic acid with a volume fraction of 5%, mix, stir evenly, place in a high-pressure reactor, and add a certain amount of The mass ratio of ionized water, deionized water and aluminum smelting waste slag is 3:1. After reacting at 200-300°C for 30-45 minutes, the acid activation products are cooled and dehydrated in turn; then put into the muffle furnace at 550°C Roast for 1-2 hours, carry out thermal activation treatment, after thermal activation treatment, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com