Preparation method of slag powder concrete material

A technology of slag powder and concrete, which is applied in the field of concrete materials, can solve the problems that affect the formwork turnover rate and production efficiency, the time for formwork removal is difficult to guarantee, and the hydration cycle is slow, so as to achieve significant economic and social benefits, strong resistance, and The effect of reducing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a slag powder concrete material preparation method, comprising the following steps:

[0033] A, prepare modified slag powder, comprise the following steps:

[0034] (1) Get the waste slag, and adjust its moisture to 15%, and grind it to a particle size of 300 mesh powder;

[0035] (2) Add cement dry powder in the waste slag according to the mass ratio of 10% of the waste slag total amount, and stir it evenly to form mixed powder;

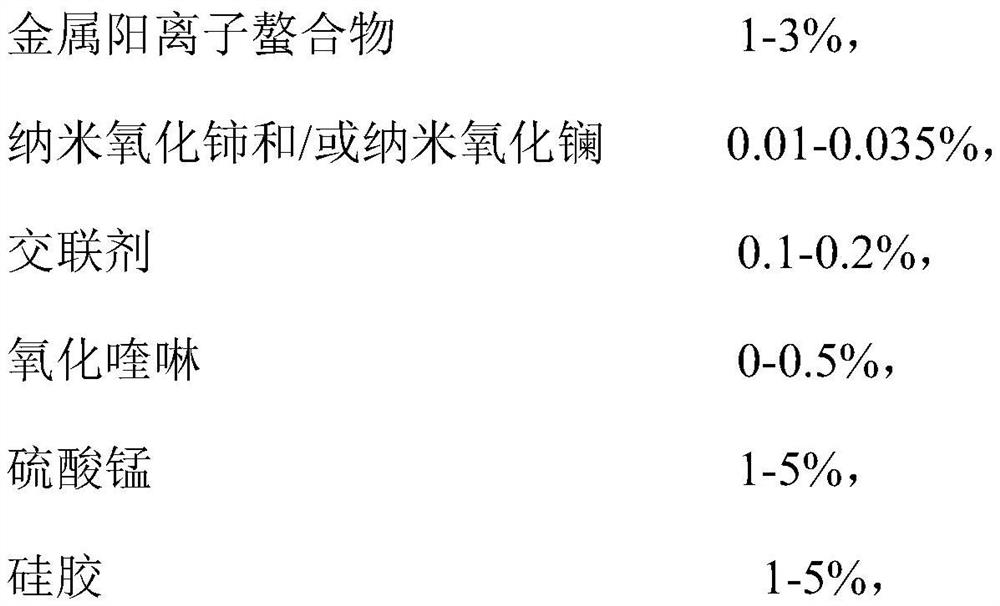

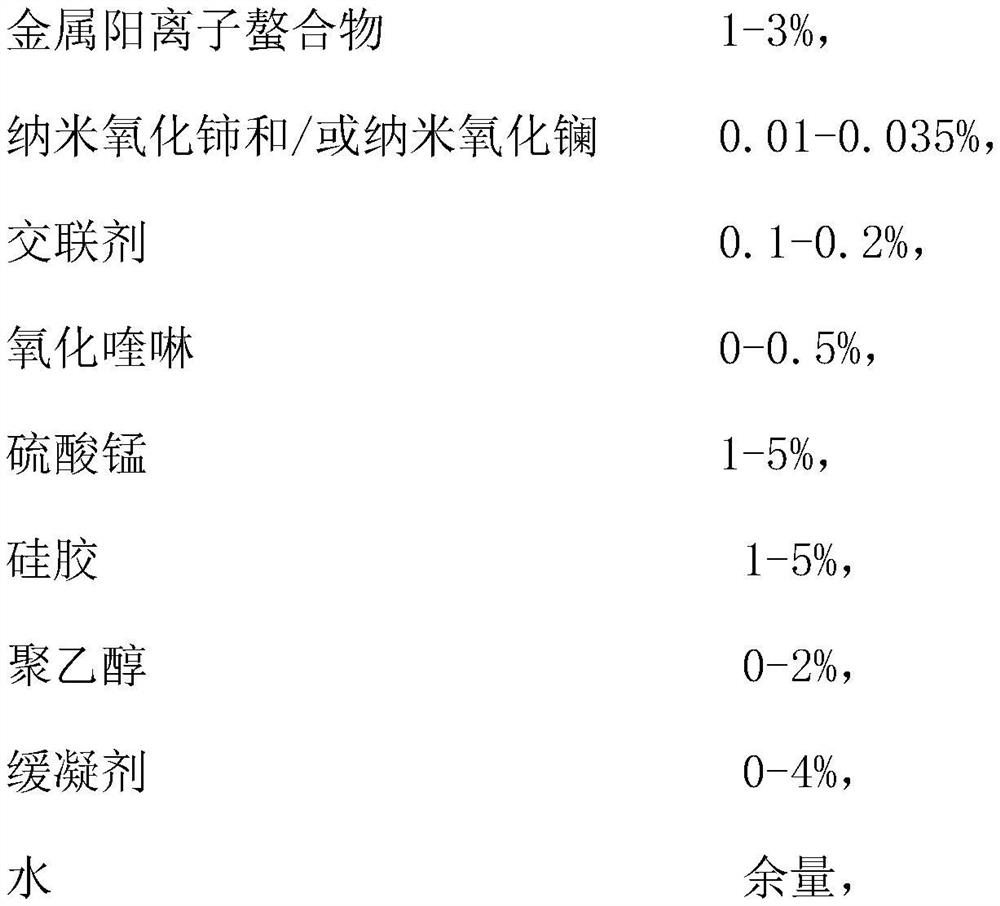

[0036] (3) Preparation of modified curing agent: 87.07% of water is placed in the container, followed by adding 2% of metal cation chelate, 0.03% of nano-cerium oxide, and 0.3% of quinoline oxide and stirring at room temperature for 4 minutes; After stirring evenly, then add 3% manganese sulfate, 1% polyethanol, and 2% borax in sequence, and continue to stir for 10 minutes; finally add 0.1% ethylenediamine, 4% silica gel, and stir for 8 minutes to prepare Modified curing agent.

[0037] (4) Add the prepared modified...

Embodiment 2

[0040] A preparation method of a slag powder concrete material preparation method, comprising the following steps:

[0041] A, prepare modified slag powder, comprise the following steps:

[0042] (1) Get the waste slag, and adjust its moisture to 10%, and grind it to a particle size of 200 mesh powder;

[0043] (2) cement dry powder is added in waste slag according to the mass ratio of 5% of waste slag total amount, and it is stirred evenly, forms mixed powder;

[0044] (3) Preparation of modified curing agent: 90.53% of water is placed in a container, followed by adding 1% of metal cation chelate, 0.01% of nano-cerium oxide, 0.01% of nano-lanthanum oxide, and 0.1% of quinoline oxide Stir at room temperature for 4 minutes; after stirring evenly, then add 5% manganese sulfate, 0.1% polyethanol, and 1% sodium phosphate in sequence, and continue stirring for 5-10 minutes; finally add 0.15% triethylenetetramine , 2% silica gel, after stirring for 8 minutes, the modified curing a...

Embodiment 3

[0048] A preparation method of a slag powder concrete material preparation method, comprising the following steps:

[0049] A, prepare modified slag powder, comprise the following steps:

[0050] (1) Get the waste slag, and adjust its moisture to 20%, and grind it to a particle size of 200 mesh powder;

[0051] (2) cement dry powder is added in waste slag according to the mass ratio of 15% of waste slag total amount, and it is stirred evenly, forms mixed powder;

[0052] (3) Preparation of modified curing agent: 84.77% of water is placed in a container, followed by adding 3% of metal cation chelate, 0.02% of nano-cerium oxide, 0.01% of nano-lanthanum oxide, and 0.4% of quinoline oxide Stir at room temperature for 4 minutes; after stirring evenly, then add 1% manganese sulfate, 0.8% polyethanol, 4% sodium fluoride, and continue stirring for 10 minutes; finally add 0.2% paraformaldehyde, 5% Silica gel, after stirring for 8 minutes, the modified curing agent was prepared.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com