Laundry condensate bead for washing wool fabrics and preparation method thereof

A technology for washing beads and woolen fabrics, applied in the preparation of detergent mixture compositions, detergent materials, detergent compositions, etc., can solve the problems of poor hand feeling, etc., achieve strong sterilization, improve solubility, The effect of improving the anti-felting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

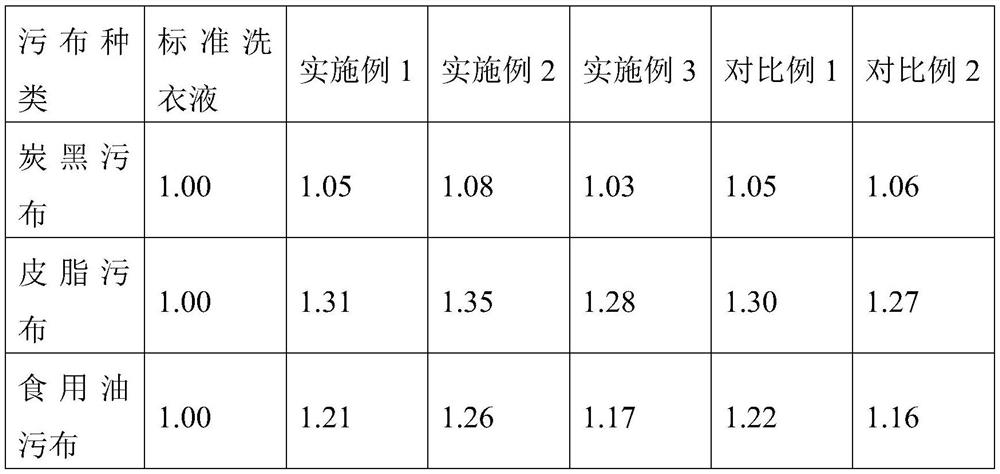

Examples

preparation example Construction

[0056] In a specific embodiment, the present application provides a laundry pod for washing woolen fabrics and a preparation method thereof, comprising the following components and their mass percentages: propylene glycol 15-25%, glycerin 5-15%, deionized water 5% ~10%, Isomerized alcohol polyether (XL-80) 15~25%, Fatty alcohol polyoxyethylene ether (AEO-7) 15%~30%, Fatty alcohol polyoxyethylene ether sodium sulfate (AES) 8~16 %, double fatty alkyl ester group hydroxyethyl methyl ammonium methyl sulfate 2-15%, cocamidopropyl betaine 2-15%, diethanolamine 0.2-0.5%, citric acid 0.05-0.1%, silver ion 0.1-0.5% of compound, 0.005-0.015% of complexing agent, 1%-3% of acrylic acid-acrylate copolymer, 0.03-0.06% of preservative, 1-2.5% of essence and 0.001-0.003% of pigment.

[0057] The isomeric alcohol ether (XL-80) described in the present invention is a kind of isomeric decanol alkoxylate, non-ionic surfactant, low foam and easy to rinse, and has excellent surface activity, wettin...

Embodiment 1

[0076] A laundry pod for washing woolen fabrics, its components and mass percentages are:

[0077] Propylene glycol 15%, glycerin 7%, deionized water 8.984%, isomeric alcohol polyether (XL-80) 20%, fatty alcohol polyoxyethylene ether (AEO-7) 16%, fatty alcohol polyoxyethylene ether sodium sulfate ( AES) 12%, di-fatty alkyl ester group hydroxyethyl methyl ammonium methyl sulfate 8%, cocamidopropyl betaine 8%, diethanolamine 0.2%, citric acid 0.02%, silver ion compound 0.25%, lanthanide 0.005% mixture, 2.5% acrylic acid-acrylate copolymer, 0.04% preservative, 2% essence and 0.001% pigment. The sum of the total amount of each component is 100%.

[0078] A laundry pod for washing woolen fabrics, the preparation method of which is:

[0079] (1) Take the raw materials of the formula according to the proportion, at room temperature, add propylene glycol, glycerin, deionized water, diethanolamine and complexing agent in the reaction kettle, mix and stir evenly;

[0080] (2) Add iso...

Embodiment 2

[0085] A laundry pod for washing woolen fabrics, its components and mass percentages are:

[0086] Propylene glycol 17%, glycerin 5%, deionized water 8.019%, isomeric alcohol polyether (XL-80) 18%, fatty alcohol polyoxyethylene ether (AEO-7) 20%, fatty alcohol polyoxyethylene ether sodium sulfate ( AES) 10%, di-fatty alkyl ester group hydroxyethyl methyl ammonium methyl sulfate 10%, cocamidopropyl betaine 8%, diethanolamine 0.2%, citric acid 0.02%, silver ion compound 0.2%, lanthanum 0.01% mixture, 1.5% acrylic acid-acrylate copolymer, 0.05% preservative, 2% essence and 0.001% pigment. The sum of the total amount of each component is 100%.

[0087] A laundry pod for washing woolen fabrics, the preparation method of which is:

[0088] (1) Take the raw materials of the formula according to the proportion, at room temperature, add propylene glycol, glycerin, deionized water, diethanolamine and complexing agent in the reaction kettle, mix and stir evenly;

[0089] (2) Add isome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com