Electrolyte for flow battery and polyhalide-chromium flow battery

A flow battery and electrolyte technology, applied in fuel cells, regenerative fuel cells, electrochemical generators, etc., can solve problems such as restricting commercial development, expensive heat dissipation equipment, and limited energy density ferrous ions, etc. Effects of high electrochemical redox activity, charge-discharge energy efficiency retention, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The electrolytic solution for the flow battery of the present invention may be a chromium-bromine electrolytic solution. The preparation scheme of the electrolyte includes, using 2.0mol of Cr(OH) 3 React with 6.0 mol of hydrochloric acid and 3.0 mol of hydrobromic acid, stir well to completely dissolve chromium hydroxide, then add a certain amount of pure water to prepare 2.0 mol / L CrCl 3 +3.0mol / L HBr chromium-bromine electrolyte 1.0L, take a certain amount of the chromium-bromine electrolyte as the positive and negative electrolytes, put it into the chromium-bromine flow battery for charge and discharge test.

[0024] When charging, the positive electrode electrolyte and the negative electrode electrolyte are sent from the positive electrode electrolyte and negative electrode electrolyte storage tanks to the positive electrode and the negative electrode respectively, and the trivalent chromium ions in the negative electrode electrolyte are reduced to divalent chromium...

Embodiment 2

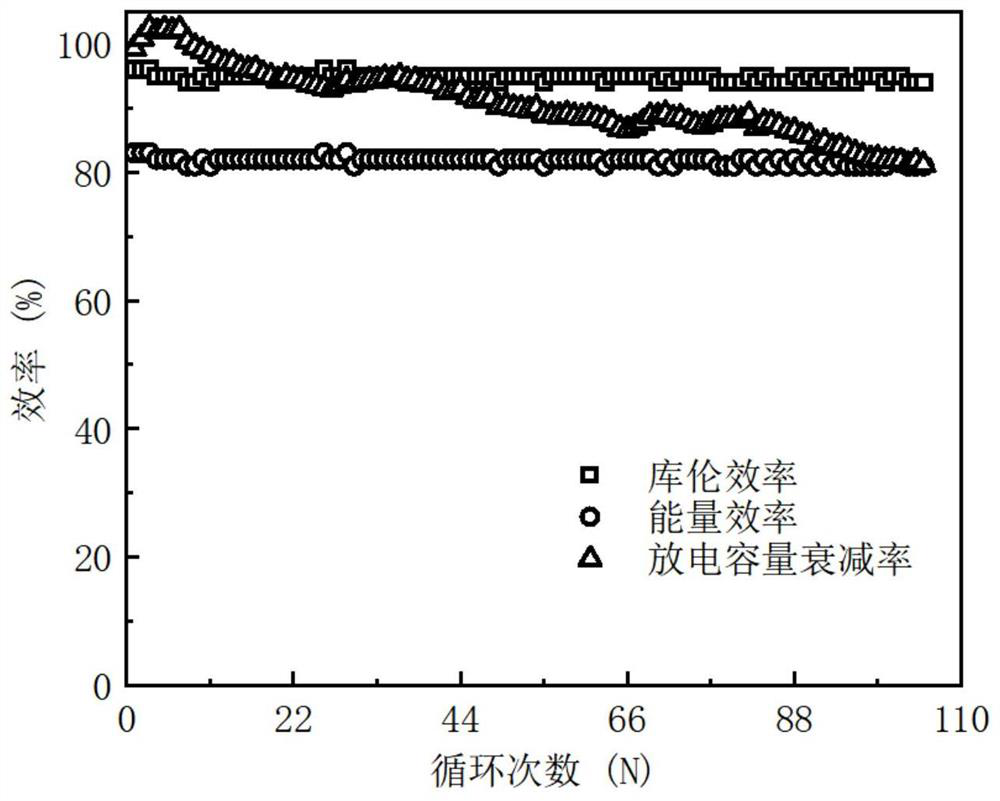

[0027] This embodiment provides a chromium-bromine electrolyte solution for a chromium-bromine flow battery, reacting 4.8 mol of chromium hydroxide with 15.4 mol of hydrochloric acid and 4.0 mol of hydrobromic acid, fully stirring to completely dissolve the chromium hydroxide, and then adding A certain amount of clear water is prepared to produce 2.4mol / L CrCl 3 +0.5mol / L HCl+2.0mol / L HBr Chromium bromine electrolyte 2.0L, divided into positive and negative chromium bromine electrolyte 1.0L each, put into chromium bromine flow battery for charge and discharge. The results show that the chromium-bromine flow battery single cell using the chromium-bromine electrolyte has a current density of 300mA cm -2 Under certain conditions, the energy efficiency reaches 85%, and the coulombic efficiency is higher than 95%.

[0028]As the battery cycle progresses, the trivalent chromium ions in the negative electrode are accompanied by hydrogen evolution reaction during charging, which will...

Embodiment 3

[0046] This embodiment provides a multi-halide-chromium flow battery, and its electrochemical performance test:

[0047] A method for preparing a polyhalide-chromium flow battery, comprising the following steps;

[0048] Step 1: Electrolyte configuration:

[0049] Positive electrode electrolyte: 25mL aqueous solution containing 3mol / L HBr and 1mol / L CrCl 3 .

[0050] Negative electrode electrolyte: 25mL aqueous solution, which contains 3mol / L HBr and 1mol / L CrCl 3 .

[0051] Step 2: Battery Assembly:

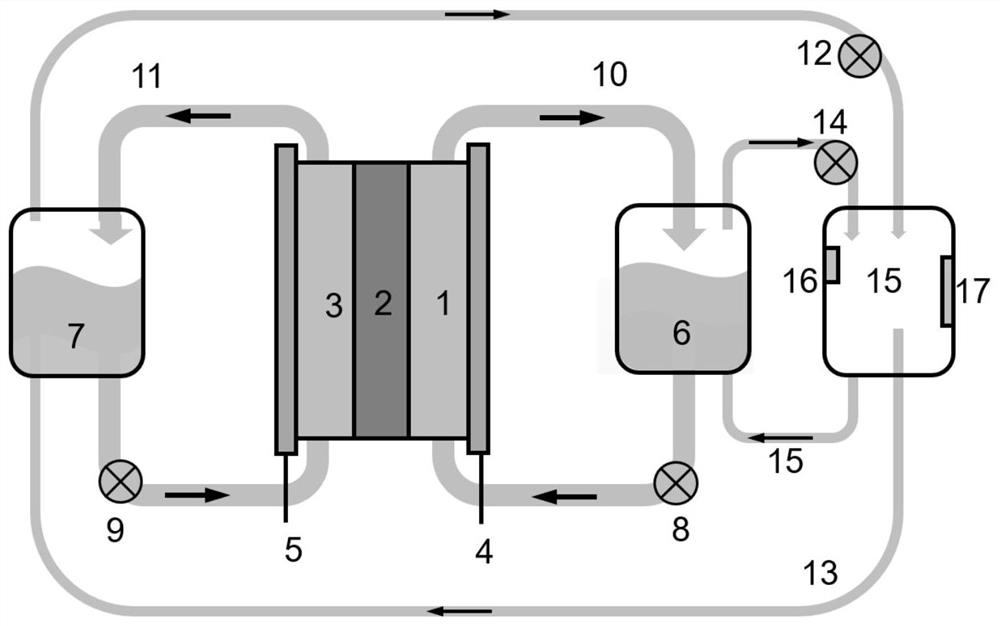

[0052] Single battery structure and system see image 3 , from left to right are positive current collector, positive electrode (2×2cm 2 carbon cloth), separator (Nafion HP), negative electrode (2×2cm 2 carbon cloth), negative current collector;

[0053] Step 3: Battery Test:

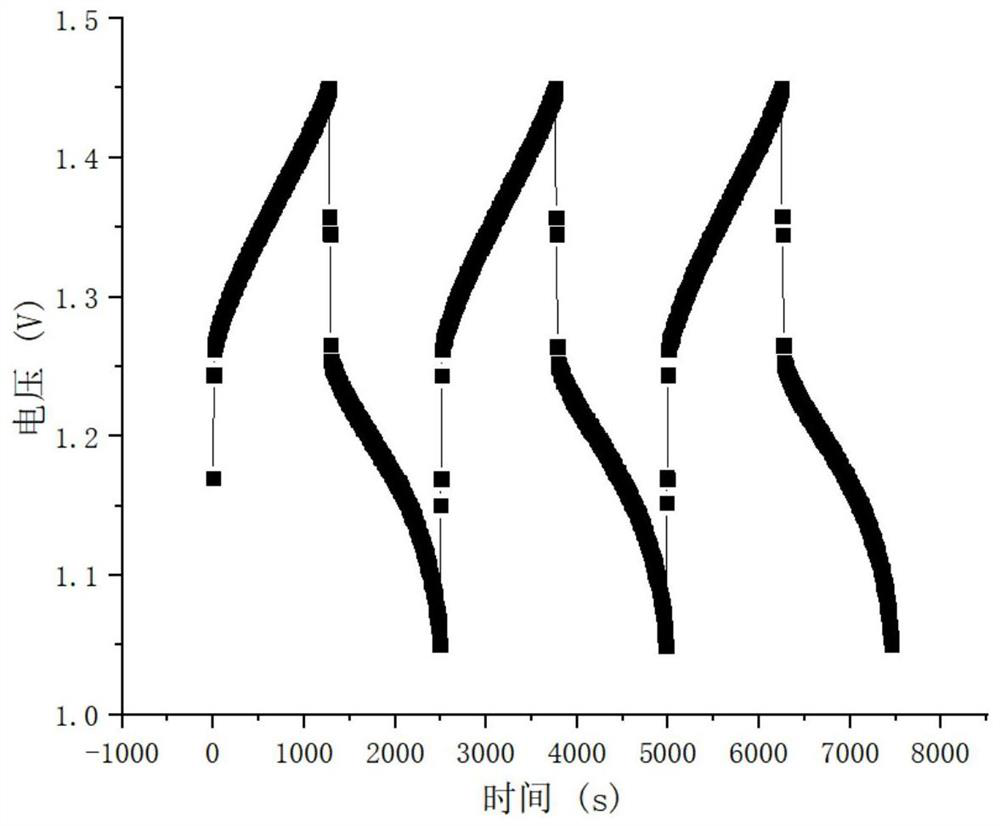

[0054] At 55 degrees Celsius, single cell at 300, 400, 500 and 600mA / cm 2 The constant current charge and discharge curve at the current density is as follows Figure 4 As shown, the operating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com