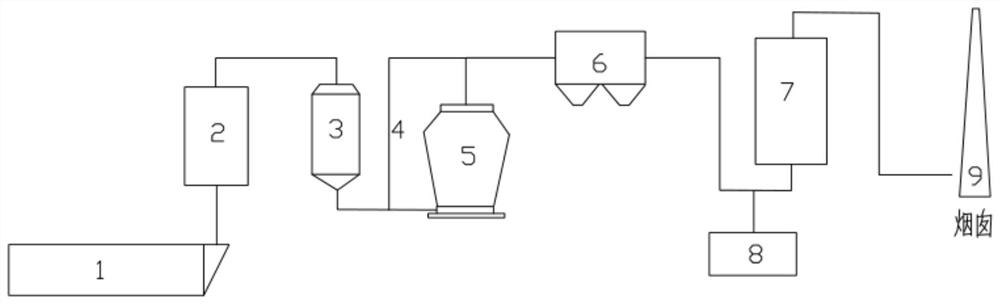

Cement kiln flue gas waste heat utilization and purification system and low-temperature SCR denitration system

A flue gas waste heat and purification system technology, applied in the field of low-temperature SCR denitrification system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Adopt the technical solution of the embodiment of the waste heat utilization and purification system of the cement kiln flue gas, wherein the cement kiln 1 is a cement kiln without an SNCR denitrification system in the furnace. During the operation of the system, the state of the dust-removed flue gas output by the dust collector 6 is: the concentration of nitrogen oxides is 300mg / Nm 3 Around, dust concentration 3 , gas volume is about 5000Nm 3 / h, the temperature is 100-150°C. The low-temperature SCR denitrification system controls the volume ratio of ammonia to nitrogen oxides to be 1.05. The denitrification efficiency of the low-temperature SCR denitrification system was measured > 80%, and the outlet NO x Concentration3 , dust concentration 3 .

Embodiment 2

[0040] Adopt the technical solution of the embodiment of the cement kiln flue gas waste heat utilization and purification system, wherein the cement kiln 1 is a cement kiln equipped with an SNCR denitrification system in the furnace. During the operation of the system, the state of the dust-removed flue gas output by the dust collector 6 is: the concentration of nitrogen oxides is 260mg / Nm 3 Around, dust concentration 3 , gas volume is about 5000Nm 3 / h, the temperature is 100-150°C. The volume ratio of ammonia to nitrogen oxides set by the SNCR denitrification system in the furnace is 1.5-1.7:1, and the volume ratio of ammonia to nitrogen oxides set by the low-temperature SCR denitrification system is 0.9-1.05:1 . The denitrification efficiency of the low-temperature SCR denitrification system was measured > 85%, and the outlet NO x Concentration3 , dust concentration 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com