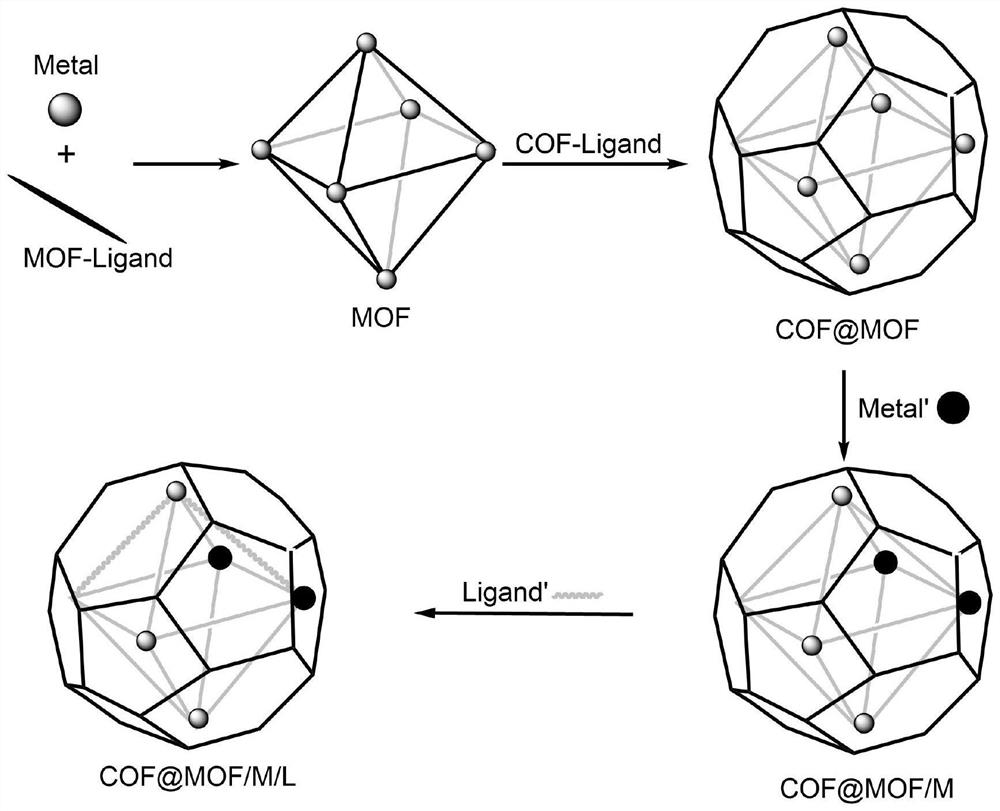

COF-coated MOF/M/L composite material and preparation method thereof

A composite material and MOF technology, which is applied in the field of COF@MOF/M/L composite materials and its preparation, can solve the problems of low removal rate of harmful substances, removal rate of only 50%, and room for improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] COF@MOF / M / L-1 Composites

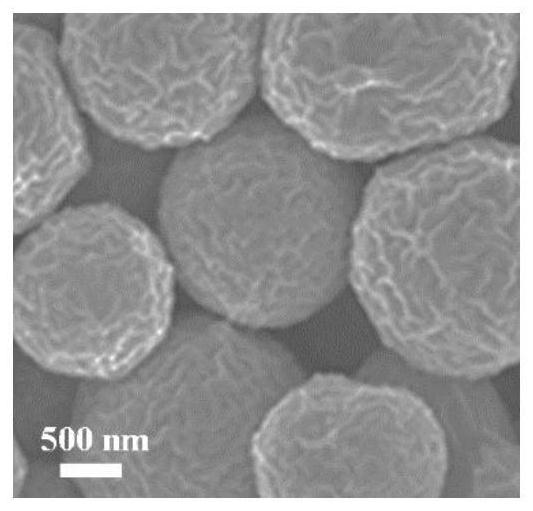

[0025] Dissolve 4.0mmol of chromium nitrate nonahydrate and 1.25mmol of 2-hydroxyterephthalic acid in 25ml of DMF, ultrasonically disperse for 5min, and react at 80°C under reflux for 24h. After the reaction, cool naturally to room temperature and centrifuge to separate the product. Wash with DMF and methanol three times, dry in an oven at 65°C for 5h, and obtain MOF-1 sample; dissolve 5mg of MOF-1 sample in DMF solution of trimesal (2M, 5mL), ultrasonically disperse for 5min, and ultrasonically disperse During the process, 1,4-dioxane (2M, 5mL) solution of p-phenylenediamine was added dropwise, ultrasonically dispersed for 1h, then the mixed solution was placed in a sealed tube, reacted at 60°C for 24h, and the product was centrifuged to obtain The solid product was washed three times with methanol and dried under vacuum at 60°C for 2h to obtain COF@MOF-1; 0.5mg of CoCl 2 Dissolve in 15mL of DMF, then add 140mg of COF@MOF-1 to it, shake the ...

Embodiment 2

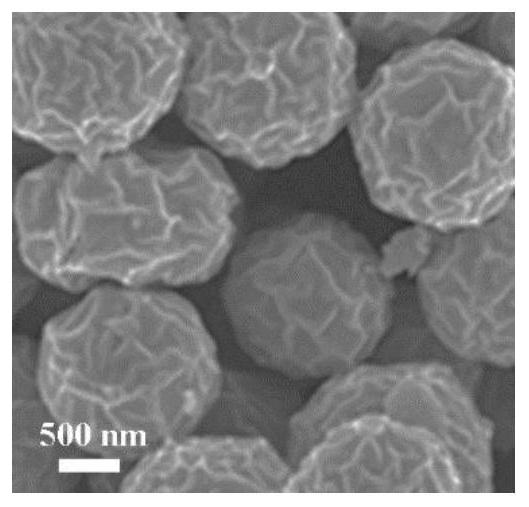

[0027] Disperse 3.8mmol of cobalt chloride and 1.15mmol of azobenzene-4,4-dicarboxylic acid in 20mL of DMF by ultrasonic dispersion, place the mixed solution in a reaction kettle, react at 120°C for 15h, and cool to room temperature naturally. The product was separated by centrifugation, washed three times with methanol, and dried in an oven at 55°C for 8 hours to obtain the MOF-2 sample; 8 mg of the MOF-2 sample was dissolved in the 1,4 - Dioxane solution (1.75M, 8mL), ultrasonically dispersed for 5min, and 0.1mL of 1M acetic acid solution was added dropwise, and 4,4,4,4-methylethanetetrayltetraphenylamine ( 2M, 3mL) solution, ultrasonically dispersed for 1 h, and then the mixed solution was placed in a sealed tube, reacted at 100 ° C for 24 h, centrifuged to separate the product, and the obtained solid product was washed three times with methanol and 1,4-dioxane, and Vacuum-dry at 60°C for 8 hours to obtain COF@MOF-2; dissolve 0.8mg of copper nitrate in 20mL of DMF, then add...

Embodiment 3

[0029] Dissolve 5.2mmol of ferric chloride and 1.8mmol of 2-methylimidazole in 30mL DMF / deionized water (1:0.2), drop acetic acid solution (0.02mL, 1M) into the ultrasonic dispersion process, and place the mixed solution In the reaction kettle, react at 140°C for 20h, naturally cool to room temperature, centrifuge the product, wash with methanol three times, and dry in an oven at 80°C for 5h to obtain the MOF-3 sample; dissolve 7mg of the MOF-3 sample in 2,5- In the DMF solution of dimethoxybenzene-1,4-dicarbaldehyde (1.5M, 10mL), ultrasonically disperse for 5min, and drop into 0.1mL of 1M hydrofluoric acid solution, drop 5,15-( Aminophenyl)-10,20-phenylporphyrin in DMF (2M, 3mL) solution, ultrasonically dispersed for 30min, then the mixed solution was placed in a sealed tube, reacted at 110°C for 48h, and the product was centrifuged to obtain a solid The product was washed three times with DMF, and vacuum-dried at 60°C for 8 hours to obtain COF@MOF-3; 0.5 mg of silver nitrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com