Method and reactor for synchronously removing heavy metals and nitrates in mine wastewater

A mine wastewater and reactor technology, which is applied in mining wastewater treatment, chemical instruments and methods, and water pollutants, etc., can solve problems such as heavy metals and nitrate pollutants exceeding the standard, and achieve the advantages of being conducive to film hanging, long service life, and active high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

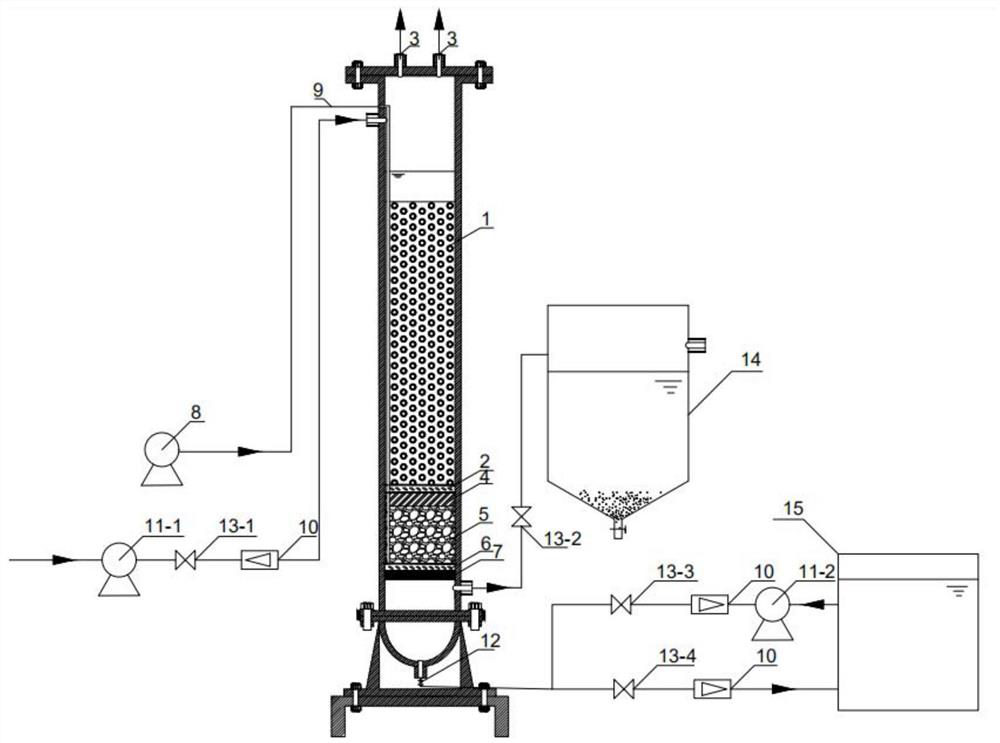

Method used

Image

Examples

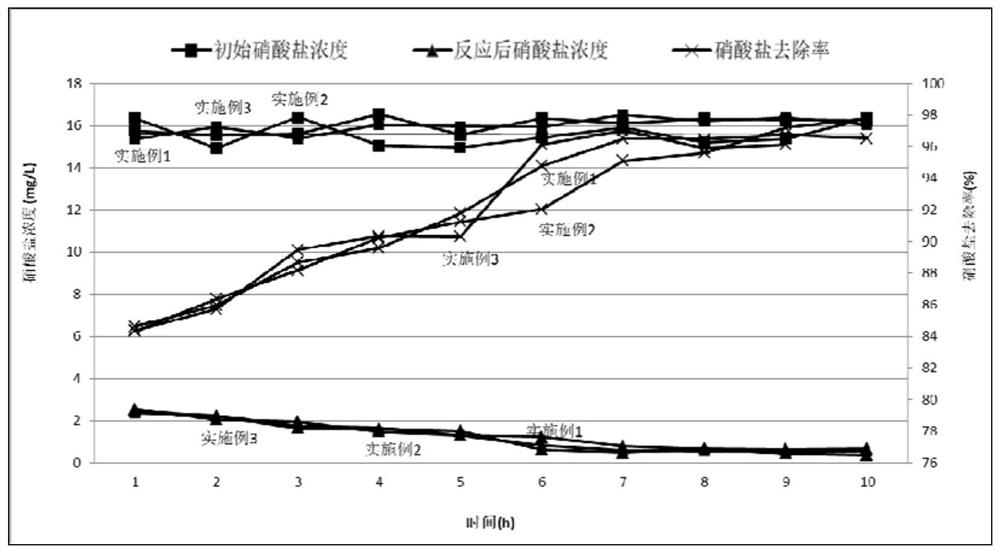

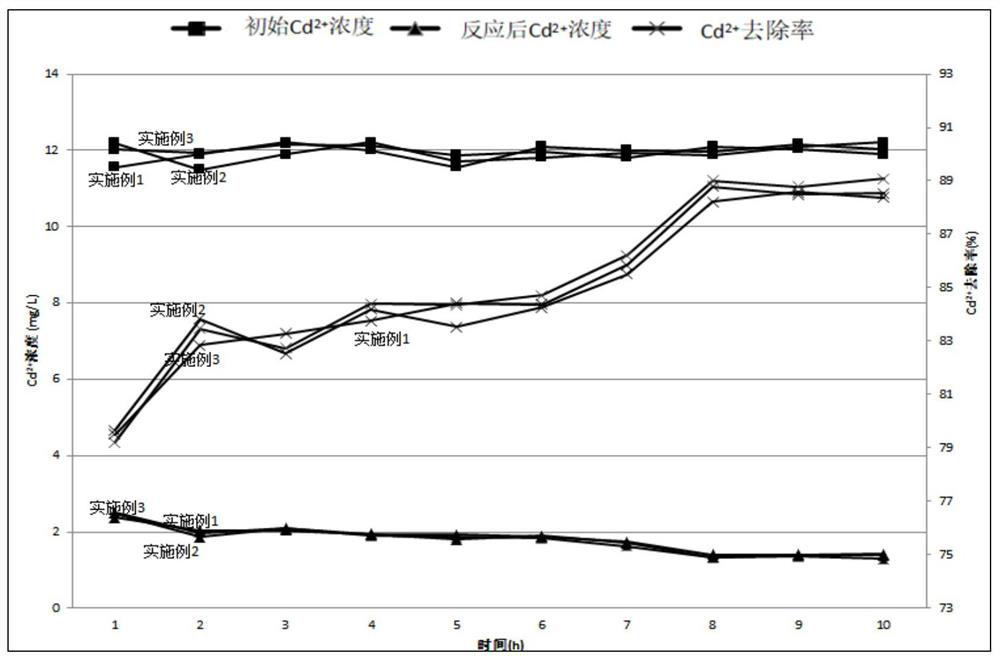

Embodiment 1

[0077] The mine waste water to be treated in this embodiment comes from the waste water of a certain mining area in Shaanxi Province, and artificially supplements nitrate and heavy metals (Cd2+ , Pb 2+ , Ni 2+ ), follow the technical scheme of the present invention, carry out advanced treatment to the water body, comprising the following steps:

[0078] Step 1, sludge enrichment and domestication:

[0079] Take 10L of the mine waste water to be treated and the FJY culture solution and mix them according to the volume ratio of 3:1, and place them in a constant temperature incubator (25-30°C) for enrichment culture. Pour 7L / min nitrogen gas into the reactor 4 times a day. , every 5 minutes, during the enrichment culture process, 7 days is a culture cycle, replace half of the supernatant with FJY culture medium, use a shaker with a speed of 140r / min, after 3 weeks of enrichment, when the nitrate removal rate Above 70%, Cd 2+ , Pb 2+ , Ni 2+ When the removal rate is above 60%...

Embodiment 2

[0105] The mine waste water to be treated in this embodiment comes from the waste water of a certain mining area in Shaanxi Province, and artificially supplements nitrate and heavy metals (Cd 2+ , Pb 2+ , Ni 2+ ), follow the technical scheme of the present invention, carry out advanced treatment to the water body, comprising the following steps:

[0106] Step 1, sludge enrichment and domestication:

[0107] Take 10L of the mine waste water to be treated and the FJY culture solution and mix them according to the volume ratio of 4:1, and place them in a constant temperature incubator (25-30°C) for enrichment culture. Pour 5L / min nitrogen gas into the reactor 4 times a day. , every 5 minutes, during the enrichment culture process, 7 days is a culture cycle, replace half of the supernatant with FJY culture medium, use a shaker with a speed of 130r / min, after 2 weeks of enrichment, when the nitrate removal rate Above 70%, Cd 2+ , Pb 2+ , Ni 2+ When the removal rate is above 6...

Embodiment 3

[0131] The mine waste water to be treated in this embodiment comes from the waste water of a certain mining area in Shaanxi Province, and artificially supplements nitrate and heavy metals (Cd 2+ , Pb 2+ , Ni 2+ ), follow the technical scheme of the present invention, carry out advanced treatment to the water body, comprising the following steps:

[0132] Step 1, sludge enrichment and domestication:

[0133] Take 10L of the mine waste water to be treated and the FJY culture solution and mix them according to the volume ratio of 2:1, and place them in a constant temperature incubator (25-30°C) for enrichment culture. Pour 8L / min nitrogen into the reactor 4 times a day. , every 5 minutes, during the enrichment culture process, 7 days is a culture cycle, replace half of the supernatant with FJY culture medium, use a shaker with a speed of 120r / min, after 3 weeks of enrichment, when the nitrate removal rate Above 70%, Cd 2+ , Pb 2+ , Ni 2+ When the removal rate is above 60%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com