Self-leveling mortar and preparation process thereof

A technology of self-leveling mortar and quartz sand, which is applied in the field of mortar, can solve the problems of insufficient self-leveling wear resistance and the inability to use the surface layer of the floor directly, and achieve the effect of smoother surface, improved wear resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: a kind of self-leveling mortar,

[0046] Prepared from the following raw materials: aluminate cement (CA-50) 90kg, water reducer (HSB aliphatic superplasticizer) 5kg, leveling agent (powder sulfonated melamine) 4kg, defoamer (AT-720B Polyether defoamer) 2kg, modified quartz sand 70kg, emulsion additive 20kg, water 20kg.

[0047] The above-mentioned modified quartz sand is ethylenediamine modified quartz sand, and the particle size of the used quartz sand is 90 mesh; the emulsion additive is a mixed emulsion of 15kg acrylate emulsion and 5kg epoxy resin emulsion, and the epoxy value of the epoxy resin used is is 0.51, and the solid content of the emulsion additive after mixing is 40%.

[0048] The preparation process is as follows:

[0049] S1: Quartz sand modification: Soak the quartz sand in ethylenediamine, stir at 80r / min for 50min at a temperature of 70°C, and filter out to obtain modified quartz sand;

[0050] S2: Stir the acrylate emulsion and epo...

Embodiment 2

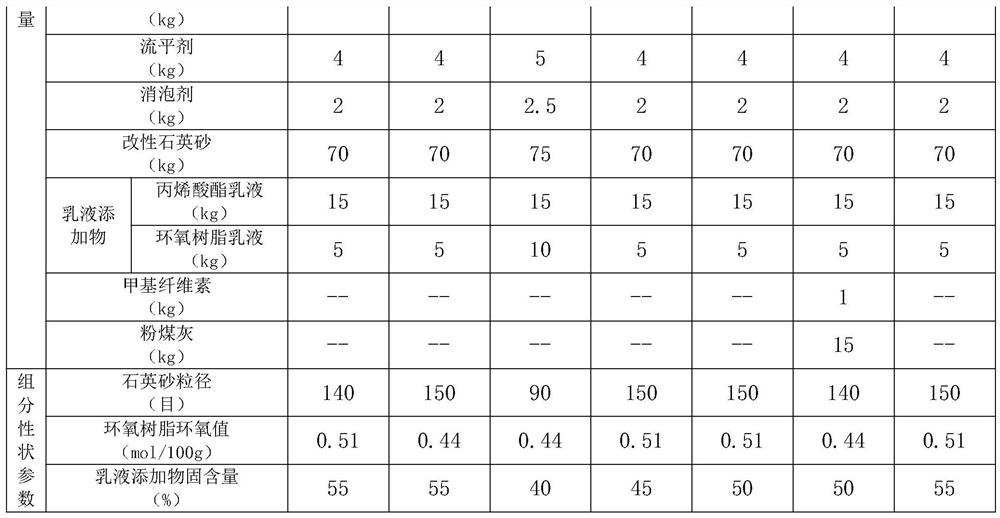

[0052] Example 2: A self-leveling mortar, the difference from Example 1 is that the dosage of each component, the performance parameters of the components and the process parameters of preparation are different, and the specific dosage and performance parameters of each component are shown in Table 1 .

[0053] The preparation process is as follows:

[0054] S1: Modification of quartz sand: Soak the quartz sand in ethylenediamine, stir at 75°C for 40min at a speed of 100r / min, filter out to obtain modified quartz sand;

[0055] S2: Stir the acrylate emulsion and epoxy resin emulsion at a speed of 250r / min for 8 minutes to obtain an emulsion additive;

[0056] S3: Preparation of mortar: Mix cement, water reducing agent, leveling agent, defoamer and modified quartz sand, and then add half of the total water consumption to the mixture for mixing to make the mixture viscous. Then add the emulsion additive and the remaining water, mix at 500r / min for 50s, reduce the stirring spee...

Embodiment 3-4

[0057] Embodiment 3-4: a kind of self-leveling mortar,

[0058] The difference from Example 1 is that methyl cellulose is added to the raw materials, and the specific dosage and performance parameters of each component are shown in Table 1.

[0059] Step S3 is changed to: preparation of mortar: mix cement, water reducing agent, leveling agent, defoamer, modified quartz sand and methyl cellulose, then add half of the total water consumption to the mixture for mixing, Make the mixture thick. Then add the emulsion additive and the remaining water, mix at 500r / min for 50s, reduce the stirring speed to 150r / min and continue stirring for 50s, obtained from leveling mortar.

[0060] The remaining process steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com