Method for preparing microbial compound organic fertilizer from domestic sludge

A domestic sludge and microbial technology, applied in the direction of microbial-based methods, the preparation of organic fertilizers, the treatment of biological organic parts, etc., can solve the problems of high cost and complicated process, and achieve the effect of improving the environment and reducing the occurrence of pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of method utilizing domestic sludge to prepare microbial composite organic fertilizer, comprises the following steps:

[0043] (1) Adjust the sludge (with a moisture content of about 80%) from the sewage treatment plant to a moisture content of less than or equal to 50% through a compressor;

[0044] (2) Add 100kg of straw, 300kg of sawdust, 60kg of bean dregs, 30kg of oil cake and 30kg of dung into 750kg of sludge (moisture content 50%), mix and stir evenly;

[0045] (3) Add 6 kg of functional compound microbial strains to the material in step (2), stir evenly to obtain a mixed material to be fermented, and adjust the moisture content of the mixed material to be fermented to 45%;

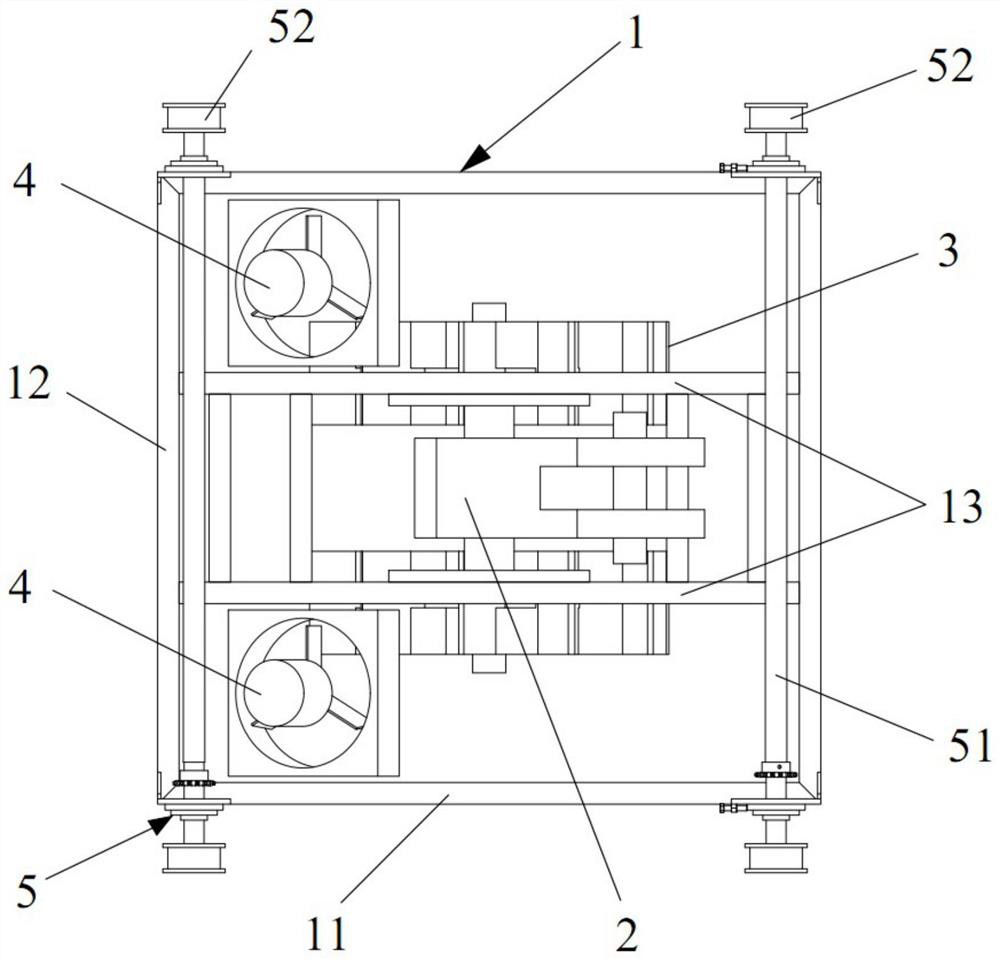

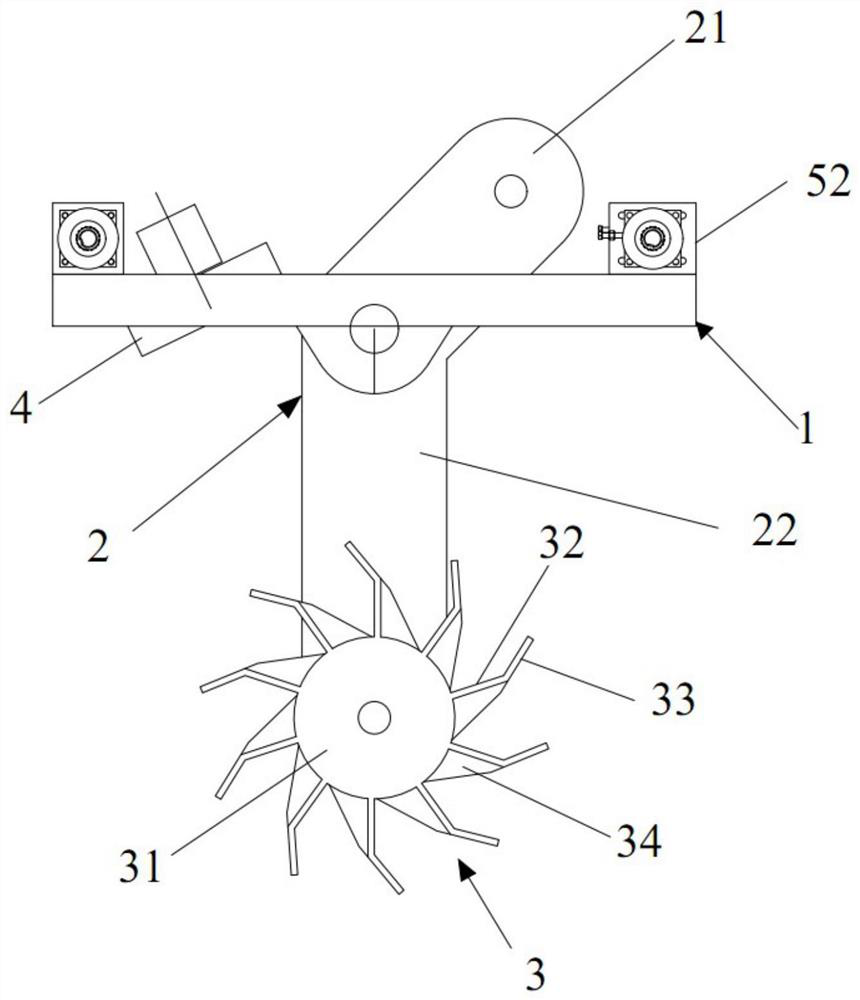

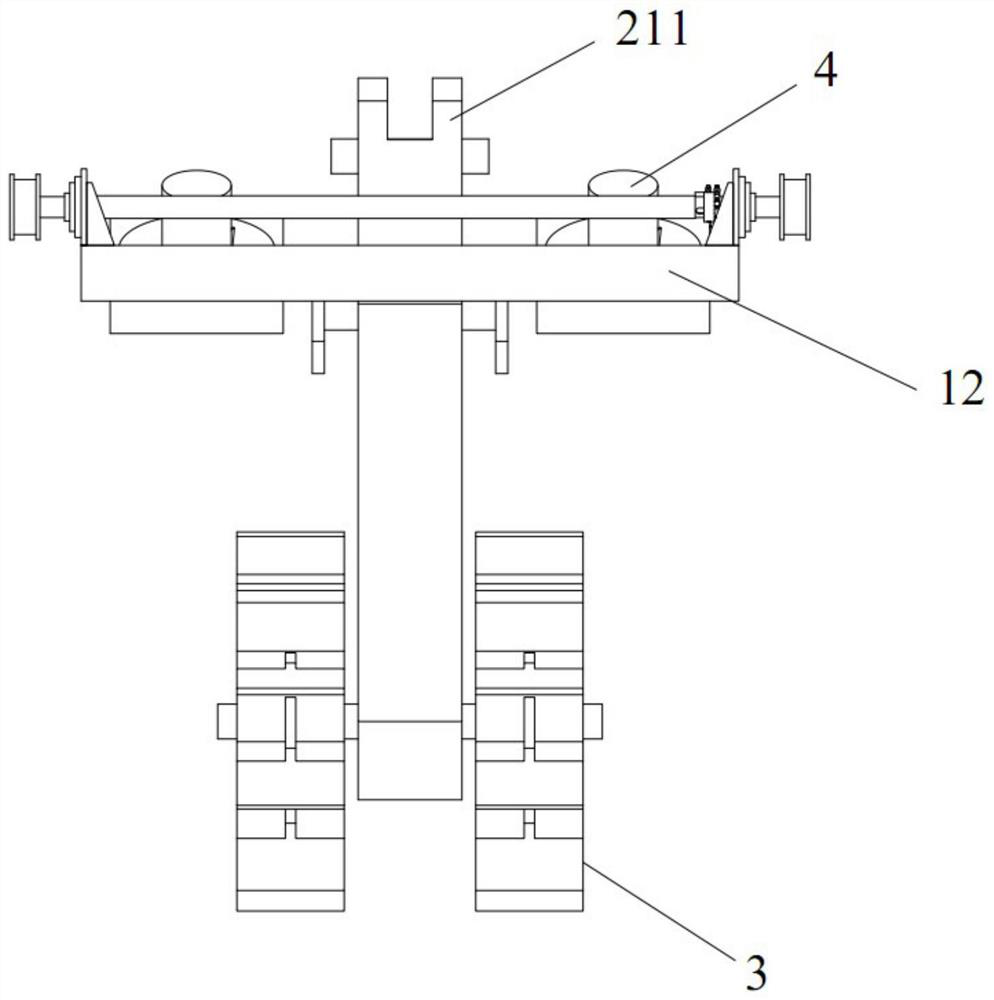

[0046] (4) Input the material evenly mixed in step (3) into the fermentation tank and spread it flat, turn on the blower to supplement oxygen, and keep static fermentation for 24 hours at a temperature of 20°C;

[0047] (5) High-temperature stirring fermentation stage: after static f...

Embodiment 2

[0052] (1) Adjust the sludge (with a moisture content of about 80%) from the sewage treatment plant to a moisture content of less than or equal to 60% through a compressor;

[0053] (2) Add 80kg of straw, 500kg of sawdust, 30kg of bean dregs, 20kg of oil cake and 20kg of dung into 650kg of sludge (moisture content 60%), mix and stir evenly;

[0054] (3) Add 4kg of functional compound microbial strains to the material of step (2), stir evenly to obtain the mixed material to be fermented, and adjust the moisture content of the mixed material to be fermented to 58%;

[0055] (4) Input the material evenly mixed in step (3) into the fermenter and spread it flat, turn on the blower to supplement oxygen, and keep static fermentation for 24 hours at a temperature of 30°C;

[0056] (5) High-temperature turning fermentation stage: after static fermentation, detect the temperature and humidity of the mixed material in the fermentation tank, keep the temperature at 60°C, keep the moisture...

Embodiment 3

[0061] (1) Adjust the sludge (with a moisture content of about 80%) from the sewage treatment plant to a moisture content of less than or equal to 50% through a compressor;

[0062] (2) Add 150kg of straw, 350kg of sawdust, 30kg of bean dregs, 20kg of oil cake and 30kg of dung into 800kg of sludge (moisture content 50%), mix and stir evenly;

[0063] (3) Add 7kg of functional composite microbial strains to the material in step (2), stir evenly to obtain a mixed material to be fermented, and adjust the moisture content of the mixed material to be fermented to 40%;

[0064] (4) Input the material evenly mixed in step (3) into the fermenter and spread it flat, turn on the blower to supplement oxygen, and keep static fermentation for 36 hours at a temperature of 10°C;

[0065] (5) High-temperature turning fermentation stage: after static fermentation, detect the temperature and humidity of the mixed material in the fermentation tank, keep the temperature at 65°C, keep the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com