Intumescent fireproof coating with ultrahigh corrosion resistance and preparation method thereof

A fire-resistant coating and anti-corrosion technology, applied in fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve the problems of incompatibility between primers and anti-corrosion intermediate paints, poor anti-corrosion and salt spray resistance, etc., and improve the ability of catalytic carbonization , Improve the effect of fire prevention, increase the effect of fire prevention and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

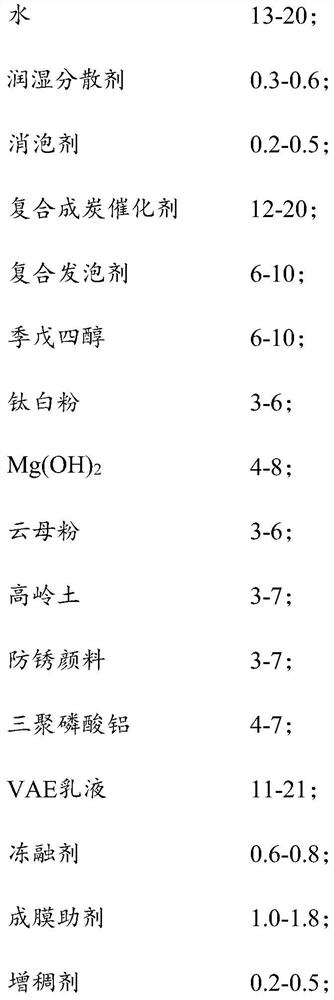

[0033] An intumescent fireproof coating with ultra-high corrosion resistance is prepared from the following raw materials according to the following mass ratio through the following steps:

[0034](1) At the speed of 300-400r / min, add 18.7% water, 0.5% dispersing wetting agent, and 0.3% defoamer to the disperser and stir for 3-5min;

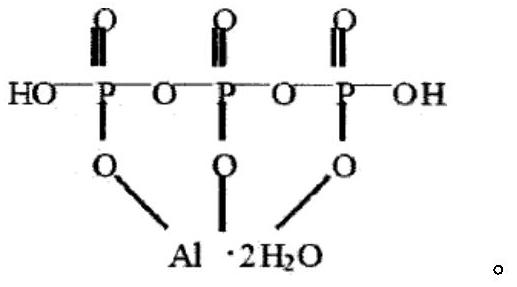

[0035] (2) At a speed of 400-900r / min, sequentially add 12% composite carbon-forming catalyst, 6% composite blowing agent, 6% pentaerythritol, 5% titanium dioxide, 8% Mg(OH) 2 , 5% mica powder, 6% kaolin, 3% rust inhibitor, 6% aluminum tripolyphosphate. Adjust the speed to 1800-2000r / min, disperse for 45-60min;

[0036] (3) Add 20% VAE emulsion, 0.7% freeze-thaw agent, 1.5% film-forming aid and 0.3% thickener at a rotating speed of 700-900r / min.

Embodiment 2

[0038] An intumescent fireproof coating with ultra-high corrosion resistance is prepared from the following raw materials according to the following mass ratio through the following steps:

[0039] (1) At the speed of 300-400r / min, add 18.7% water, 0.5% dispersing wetting agent, and 0.3% defoamer to the disperser and stir for 3-5min;

[0040] (2) At the speed of 400-900r / min, sequentially add 16% composite carbon-forming catalyst, 7% composite blowing agent, 7% pentaerythritol, 5% titanium dioxide, 7% Mg(OH) 2 , 4% mica powder, 4% kaolin, 3% rust inhibitor, 5% aluminum tripolyphosphate. Adjust the speed to 1800-2000r / min, disperse for 45-60min;

[0041] (3) Add 20% VAE emulsion, 0.7% freeze-thaw agent, 1.5% film-forming aid and 0.3% thickener at a rotating speed of 700-900r / min.

Embodiment 3

[0043] An intumescent fireproof coating with ultra-high corrosion resistance is prepared from the following raw materials according to the following mass ratio through the following steps:

[0044] (1) At the speed of 300-400r / min, add 18% water, 0.5% dispersing wetting agent, and 0.3% defoamer to the disperser and stir for 3-5min;

[0045] (2) At the speed of 400-900r / min, add 18% composite carbon-forming catalyst, 9% composite blowing agent, 8% pentaerythritol, 5% titanium dioxide, 5% Mg(OH) in sequence 2 , 4% mica powder, 3% kaolin, 3% rust inhibitor, 5% aluminum tripolyphosphate. Adjust the speed to 1800-2000r / min, disperse for 45-60min;

[0046] (3) Add 19% VAE emulsion, 0.7% freeze-thaw agent, 1.2% film-forming aid and 0.3% thickener at a rotating speed of 700-900r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com