Preparation method of anti-pilling agent for blended fabrics

A pilling agent and a technology for blended fabrics, which are applied in textiles and papermaking, animal fibers, and improved hand-feeling fibers, etc., can solve the problem of unsatisfactory anti-pilling effect of imitation cashmere fabrics, unsuitable for industrial use, and hard fabrics. problem, to achieve the effect of good anti-pilling balloon performance, not easy to delaminate, and soft to the touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

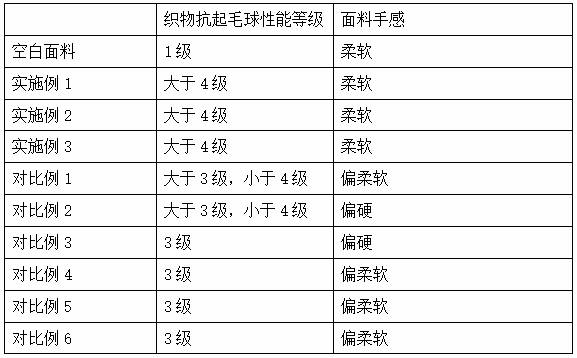

Examples

Embodiment 1

[0019] A preparation method of an anti-pilling agent for blended fabrics, comprising a polymerized emulsion of methacrylate and an organic silicon polymerized emulsion, the production method comprising the following steps:

[0020] (1) Preparation of polymerized emulsion of methacrylate

[0021] Under anaerobic conditions, add 18 parts of isooctyl methacrylate, 12 parts of hydroxyethyl methacrylate, 4 parts of secondary alkyl diester sodium sulfonate (TAS60), and 1 part of L-90 emulsifier into the reaction vessel , 1 part of AEO-9 emulsifier, 1 part of isomeric tridecyl alcohol polyoxyethylene ether, and 60 parts of deionized water. Adjust the pH to 5-6, stir well and make a pre-emulsion. Then heat up 140 parts of quantitative deionized water to 75-80°C, then add 0.1 part of initiator ammonium persulfate, and add the pre-emulsion dropwise at the same time. The time for dropping is 3.5 hours, and the time for keeping warm is 4 hours. At room temperature, a polymerized emulsio...

Embodiment 2

[0028] (1) Preparation of polymerized emulsion of methacrylate

[0029] Under anaerobic conditions, add 15 parts of isooctyl methacrylate, 10 parts of hydroxyethyl methacrylate, 3 parts of secondary alkyl diester sodium sulfonate (TAS60), and 1 part of L-90 emulsifier into the reaction vessel , 2 parts of AEO-9 emulsifier, 1 part of isomeric tridecyl alcohol polyoxyethylene ether, and 50 parts of deionized water. Adjust the pH to 5-6, stir well and make a pre-emulsion. Then heat up 100 parts of deionized water to 75-80°C, then put in 0.05 parts of initiator potassium persulfate, and add the pre-emulsion dropwise at the same time, the time of dropping is 3 hours, the time of keeping warm is 4 hours, and then cool down to room temperature , the polymerized emulsion of methacrylate can be obtained.

[0030] (2) Preparation of silicone polymer emulsion

[0031] First, 300 parts of octamethylcyclotetrasiloxane and 5 parts of N-cyclohexyl-γ-aminopropylmethyldimethoxysilane coupli...

Embodiment 3

[0036] (1) Preparation of polymerized emulsion of methacrylate

[0037] Under anaerobic conditions, add 20 parts of isooctyl methacrylate, 15 parts of hydroxyethyl methacrylate, 6 parts of secondary alkyl diester sodium sulfonate (TAS60), and 2 parts of L-90 emulsifier into the reaction vessel , 1 part of AEO-9 emulsifier, 2 parts of isomeric tridecyl polyoxyethylene ether, and 60 parts of deionized water. Adjust the pH to 5-6, stir well and make a pre-emulsion. Then heat up 150 parts of deionized water to 75-80°C, then add 0.4 parts of initiator ammonium persulfate, and add the pre-emulsion dropwise at the same time. , the polymerized emulsion of methacrylate can be obtained.

[0038] (2) Preparation of silicone polymer emulsion

[0039] First, 400 parts of octamethylcyclotetrasiloxane and 15 parts of N-cyclohexyl-γ-aminopropylmethyldimethoxysilane coupling agent were sheared at high speed to obtain A uniformly, and after adding 1500 parts of deionized water, 50-80 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com