Micro-nano single crystal flexible photoelectric detector with groove array structure and preparation method thereof

A photodetector and array structure technology, which is applied in photovoltaic power generation, electric solid-state devices, organic semiconductor devices, etc., can solve the problem of less research on micro-nano structure regulation of photodetector devices, and achieve the effect of enhancing photoelectric detection performance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

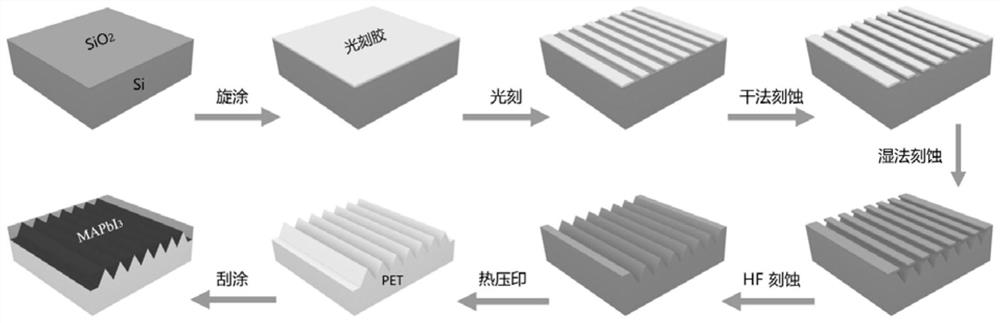

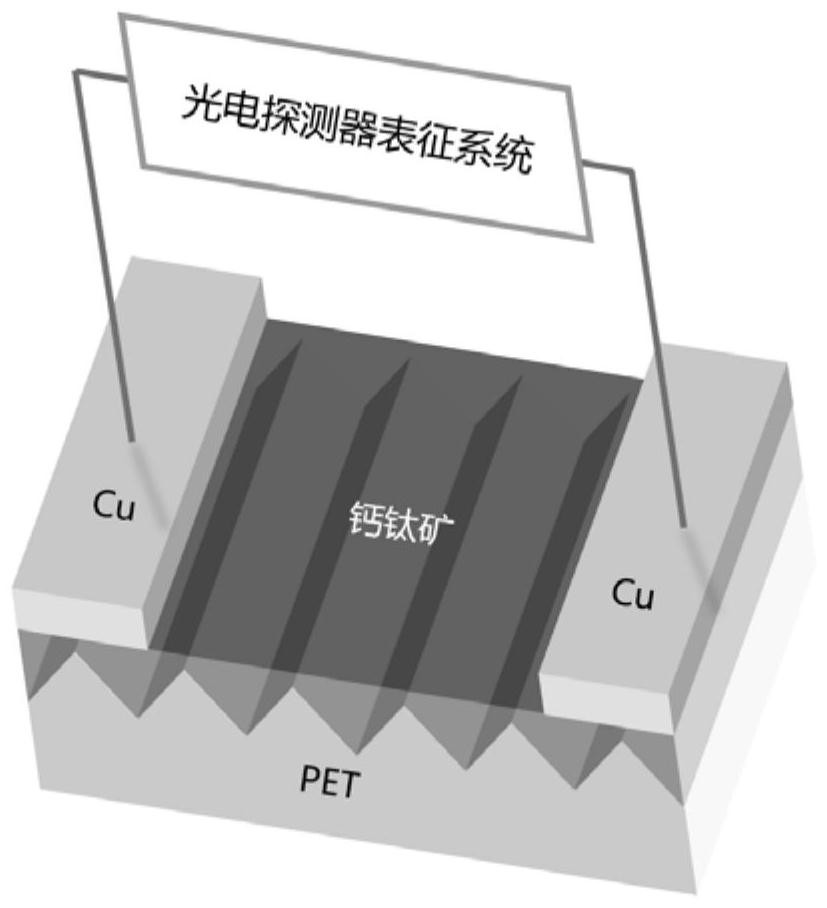

[0037] The preparation process of perovskite micro-nano single crystal flexible photodetector with enhanced photoelectric performance with trench array structure is as follows: figure 1 As shown, it specifically includes the following steps:

[0038] 1) Preparation of groove array micro-nano structure silicon template

[0039] 1-1) Clean the silicon wafer whose surface is covered with silicon dioxide with a thickness of 300 nanometers:

[0040] Ultrasonic cleaning with concentrated sulfuric acid for 20-30 minutes;

[0041] Ultrasonic cleaning with deionized water for 20-30 minutes;

[0042] Ultrasonic cleaning with ethanol for 20-30 minutes;

[0043] Ultrasonic cleaning with acetone for 20-30 minutes;

[0044] Wash with isopropanol for 20-30 minutes.

[0045] 1-2) Oxygen plasma etching

[0046] The cleaned silicon substrate needs to be dried with a nitrogen flow, and then placed in a dry etcher, and etched with oxygen plasma for 3-5 minutes, so as to improve the surface ...

Embodiment 2

[0068] A method for preparing a micro-nano single crystal flexible photodetector with a trench array structure, the method comprising the following steps:

[0069] 1) Prepare a silicon template with groove array micro-nano structure:

[0070] 1-1) cleaning the silicon wafer with a silicon dioxide layer on the surface;

[0071] 1-2) performing oxygen plasma etching on the cleaned silicon wafer;

[0072] 1-3) spin coating photoresist on the silicon dioxide layer of silicon wafer;

[0073] 1-4) performing deep ultraviolet lithography on the photoresist on the silicon dioxide layer;

[0074] 1-5) developing the silicon wafer after photolithography, and cleaning off the unexposed photoresist;

[0075] 1-6) dry etching the silicon dioxide layer on the silicon wafer;

[0076] 1-7) wet etching the silicon wafer after dry etching;

[0077] 1-8) Remove the remaining SiO on the surface of the silicon wafer 2 , to obtain a silicon template with a groove array micro-nano structure; ...

Embodiment 3

[0093] A method for preparing a micro-nano single crystal flexible photodetector with a trench array structure, the method comprising the following steps:

[0094] 1) Prepare a silicon template with groove array micro-nano structure:

[0095] 1-1) cleaning the silicon wafer with a silicon dioxide layer on the surface;

[0096] 1-2) performing oxygen plasma etching on the cleaned silicon wafer;

[0097] 1-3) spin coating photoresist on the silicon dioxide layer of silicon wafer;

[0098] 1-4) performing deep ultraviolet lithography on the photoresist on the silicon dioxide layer;

[0099] 1-5) developing the silicon wafer after photolithography, and cleaning off the unexposed photoresist;

[0100] 1-6) dry etching the silicon dioxide layer on the silicon wafer;

[0101] 1-7) wet etching the silicon wafer after dry etching;

[0102] 1-8) Remove the remaining SiO on the surface of the silicon wafer 2 , to obtain a silicon template with a groove array micro-nano structure; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com