Preparation method of lead-acid battery negative plate and lead-acid battery

A lead-acid battery and negative plate technology, applied in the direction of lead-acid battery electrodes, lead-acid batteries, battery electrodes, etc., can solve the problems of high cost, complicated process, high pollution, etc., achieve low recycling cost, simple process, overcome energy costly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] At first, the invention provides a kind of preparation method of lead-acid battery negative plate, and this method comprises the steps:

[0032] 1) crushing waste lead-acid batteries, and separating to obtain lead paste;

[0033] 2) Soaking the above-mentioned lead plaster in the aqueous solution of the first dilute acid and / or the first dilute acid salt, filtering and drying the soaked lead plaster;

[0034] 3) adding additives and a second dilute acid to the dried lead paste for paste treatment to obtain negative electrode lead paste;

[0035] 4) Coating the negative electrode lead paste on the surface of the negative electrode lead grid, and obtaining a negative electrode plate after curing.

[0036] Specifically, the present invention uses conventional methods in the field to crush waste lead-acid batteries, such as mechanical crushing, and the crushed lead-acid batteries are separated to obtain lead paste, which may contain active substances of lead-acid batteries...

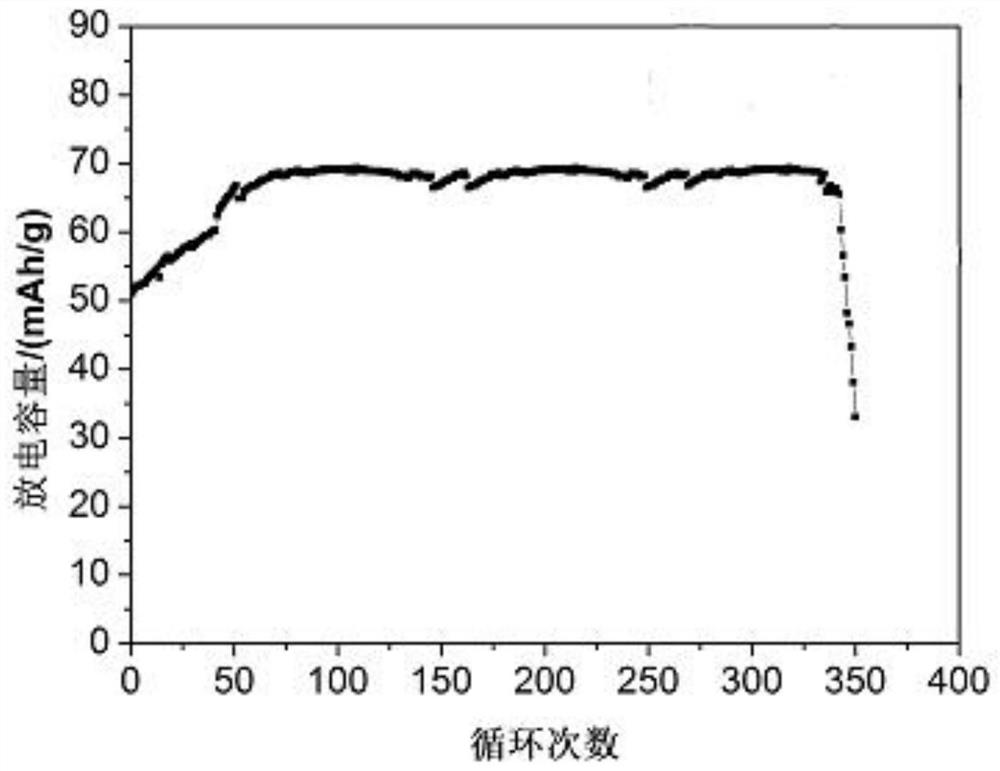

Embodiment 1

[0055] The present embodiment provides a kind of preparation method of lead-acid battery, and this method comprises the steps:

[0056] 1) After mechanically crushing and separating 1 kg of waste lead-acid batteries, a mixed lead paste is obtained;

[0057] 2) Add 10L of a mixed solution of 0.1mol / L sulfuric acid and 0.1mol / L ammonium sulfate to the lead paste, soak for 1 hour, filter to remove impurities with large particle sizes, and then dry the filtrate at 160°C;

[0058] 3) Get 40g of dried lead plaster, and add 0.130g acetylene black, 0.072g lignin, 0.033g short fiber, 0.052g humic acid, 0.4g barium sulfate, 3.2g 8.7mol / L sulfuric acid and 3g deionized water is carried out and paste treatment, obtains negative electrode lead paste;

[0059] 4) Apply the above-mentioned negative electrode lead paste on a 5.5cm×6.5cm negative electrode lead grid, and dry it to make a negative electrode plate containing 20g of active material.

[0060] Manufacture of lead-acid battery: As...

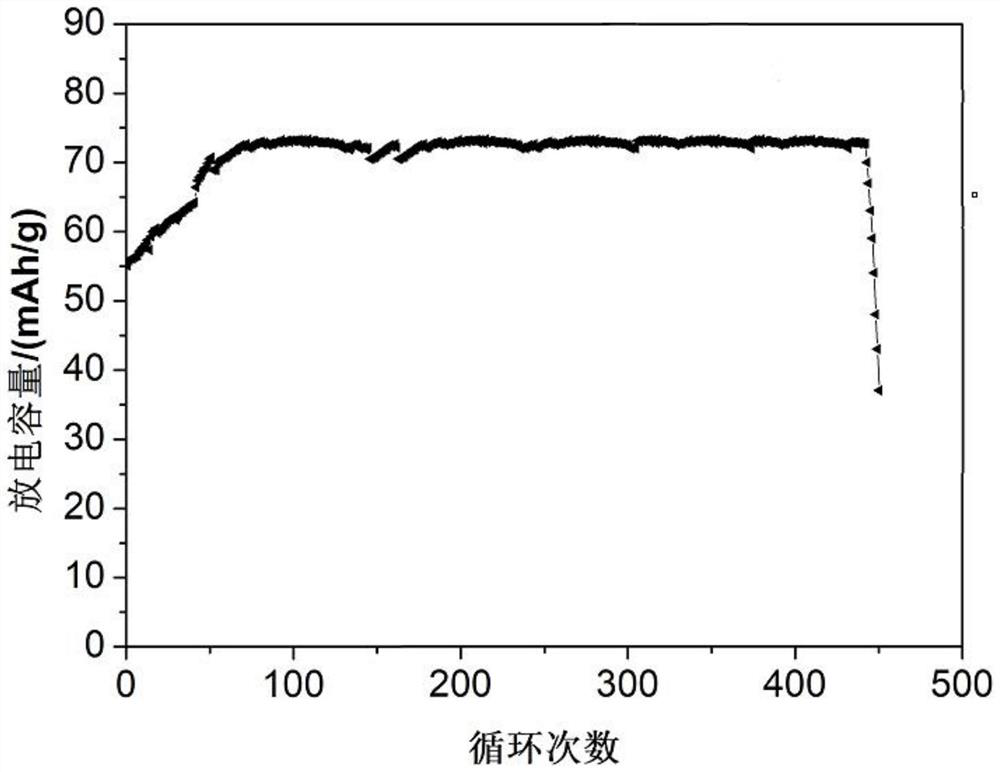

Embodiment 2

[0072] The present embodiment provides a kind of preparation method of lead-acid battery, and this method comprises the steps:

[0073] 1) After mechanically crushing and separating 1 kg of waste lead-acid batteries, a mixed lead paste is obtained;

[0074] 2) Add 10L of a mixed solution of 0.1mol / L malic acid and 0.1mol / L sodium malate to the lead paste, soak for 1 hour, filter to remove impurities with large particle sizes, and then dry the filtrate at 120°C;

[0075] 3) Get 40g of dried lead plaster, and add 0.130g acetylene black, 0.072g lignin, 0.033g short fiber, 0.052g humic acid, 0.4g barium sulfate, 3.2g 8.7mol / L sulfuric acid and 3g deionized water is carried out and paste treatment, obtains negative electrode lead paste;

[0076] 4) Apply the above-mentioned negative electrode lead paste on a 5.5cm×6.5cm negative electrode lead grid, and dry it to make a negative electrode plate containing 20g of active material.

[0077]Manufacture of lead-acid battery: Assemble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com