Semiconductor laser and optical fiber coupling structure

A fiber coupling and semiconductor technology, which is applied in the field of semiconductor laser devices, can solve the problems of reducing the electro-optical efficiency of semiconductor lasers, low chip output power density, and reducing the effect of space hole burning, etc., to achieve small size, light weight, and reduced quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

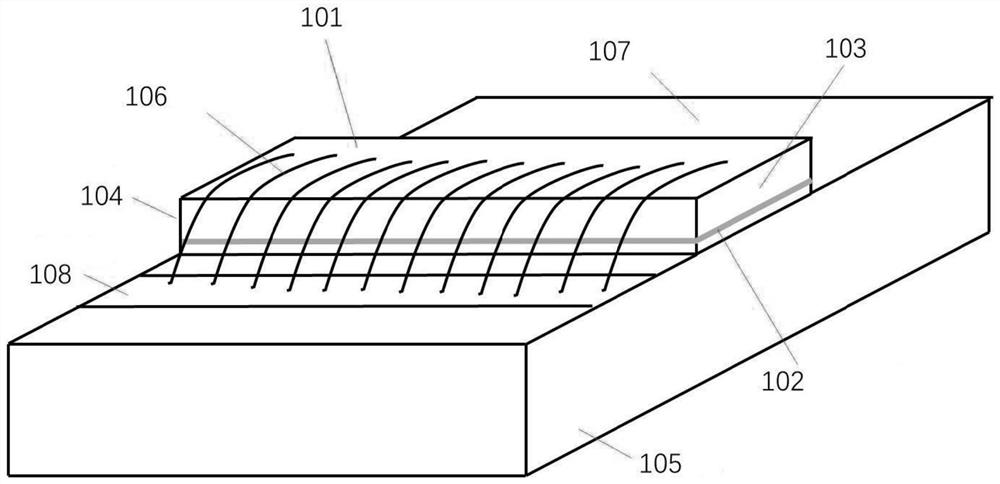

[0035] Such as figure 1 As shown, a semiconductor laser 201 is specifically provided in this embodiment, aiming at improving the total laser output power by optimizing and improving the semiconductor laser 201 . The semiconductor laser in this embodiment includes: a semiconductor laser chip 101 , and in this embodiment, the semiconductor laser chip 101 is a 790nm semiconductor laser chip 101 .

[0036] The semiconductor laser chip 101 is provided with two light-emitting surfaces, respectively the first light-emitting surface 103 and the second light-emitting surface 104, the first light-emitting surface 103 and the second light-emitting surface 104 are symmetrically arranged and the first light-emitting surface 103 and the second light-emitting surface The reflectivity of 104 is set equal, and the semiconductor laser chip 101 outputs laser beams from the first light-emitting surface 103 and the second light-emitting surface 104 respectively.

[0037] The advantage of the desi...

Embodiment 2

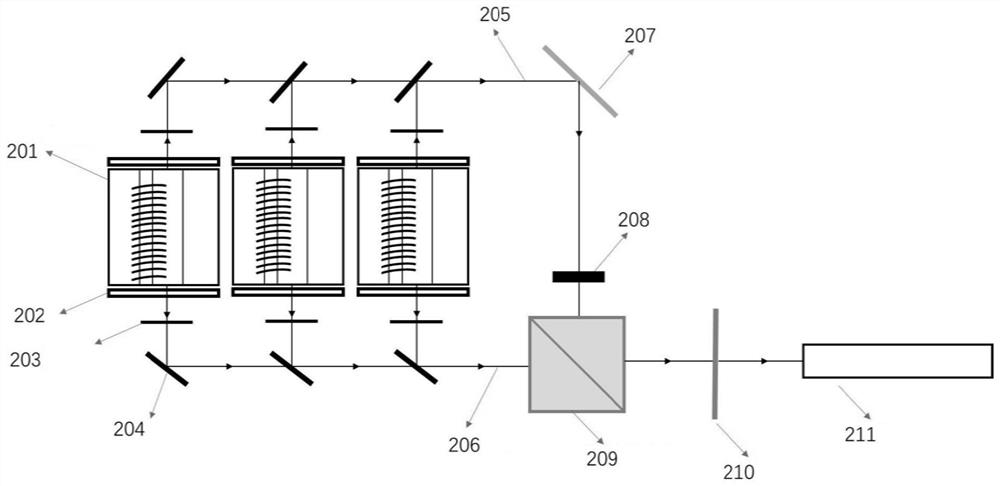

[0041] Such as figure 2 As shown, a fiber coupling structure is specifically provided in this embodiment, aiming to improve the electro-optical conversion efficiency of the chip and reduce the number of semiconductor laser chips 101 in the coupling structure through the fiber coupling structure. The fiber-coupled structure includes:

[0042]A plurality of semiconductor lasers 201 are arranged in an array, and each semiconductor laser 201 is equidistantly arranged in parallel along the same direction. Each of the semiconductor lasers 201 adopts the improved 790nm semiconductor laser 201 in Embodiment 1.

[0043] The laser beams output by the first light-emitting surface 103 of each of the semiconductor lasers 201 respectively pass through the fast-axis collimating mirror FAC202, the slow-axis collimating mirror SAC203 and the step mirror 204 arranged in sequence to generate first parallel beams 205 with different heights; The laser beam output by the second light-emitting sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com