Preparation method of spherical alpha-cobalt hydroxide and spherical alpha-cobalt hydroxide

A cobalt hydroxide, spherical technology, applied in the direction of cobalt oxide/cobalt hydroxide, electrochemical generators, structural parts, etc., can solve the problems of complex preparation process, increased cobalt loss, increased cost, etc., to avoid excessive OH- , Low Co loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention provides α-Co(OH) 2 The preparation method comprises the following steps:

[0040] (1) Take soluble cobalt chloride and dissolve in water to obtain soluble cobalt chloride solution.

[0041](2) Add a mixed solution of triethylamine and tripropylamine to the clarified solution of soluble cobalt salt, the molar ratio of triethylamine and tripropylamine in the mixed solution is 40:60, control the reaction temperature to 65°C, and the stirring rate to 480r / min, after the reaction is over, the solid-liquid separation will give blue-cyan α-Co(OH) 2 Solid and organic amine salt solutions;

[0042] 3) Add quicklime to the organic amine salt solution, react to generate calcium chloride and organic amine liquid, and finally obtain a mixed solution containing calcium chloride and organic amine, and then separate and recover the organic amine in the mixed solution for step 2).

Embodiment 2

[0044] (1) Weigh soluble cobalt nitrate and dissolve in water to obtain soluble cobalt nitrate solution.

[0045] (2) Add the mixed solution of tripropylamine and tributylamine in the cobalt nitrate solution, the molar ratio of triethylamine and tripropylamine in the mixed solution is 20:80, control the reaction temperature to be 55°C, and the stirring rate to be 560r / min, After the reaction is completed, the solid-liquid separation will give blue-cyan α-Co(OH) 2 Solid and organic amine salt solutions;

[0046] 3) adding calcium hydroxide to the organic amine salt solution to react to obtain a mixed solution containing calcium nitrate and organic amine, and then separating and recovering the organic amine in the mixed solution for step 2).

Embodiment 3

[0048] (1) Weigh soluble cobalt nitrate and dissolve in water to obtain soluble cobalt nitrate solution.

[0049] (2) Add tributylamine solution to the cobalt nitrate solution, control the reaction temperature to 60°C, and the stirring rate to 550r / min. After the reaction is completed, the solid-liquid separation will give blue cyan α-Co(OH) 2 Solid and organic amine salt solutions;

[0050] 3) adding calcium hydroxide to the organic amine salt solution to react to obtain a mixed solution containing calcium nitrate and organic amine, and then separating and recovering the organic amine in the mixed solution for step 2).

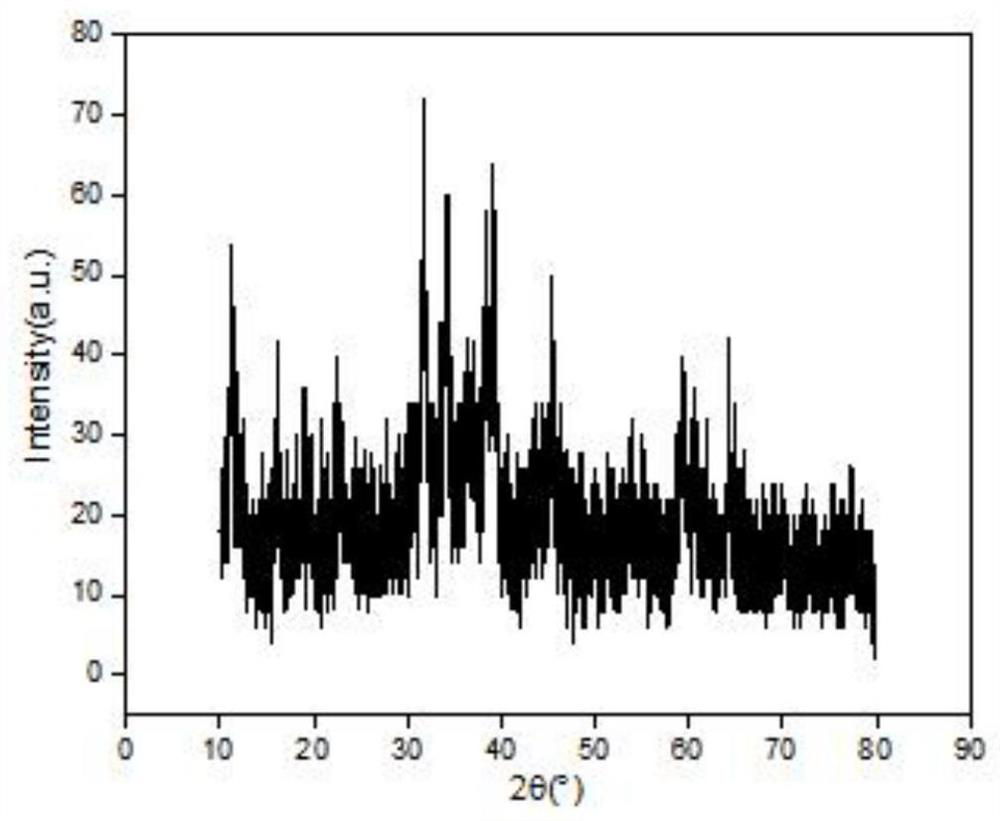

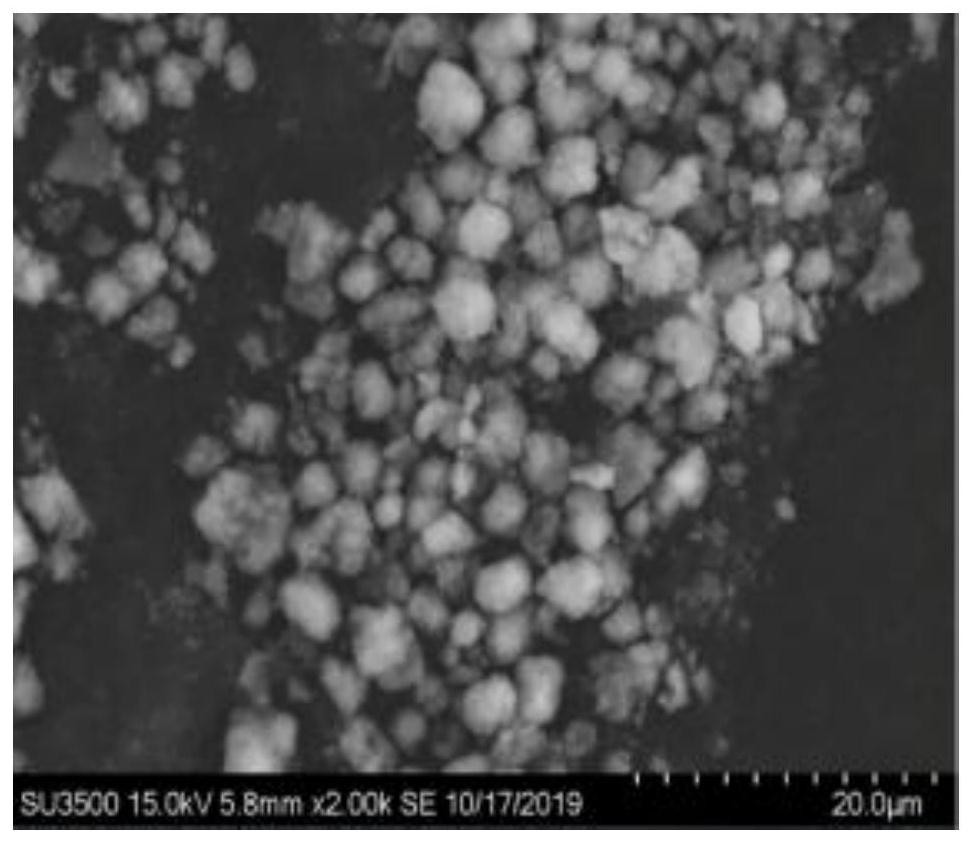

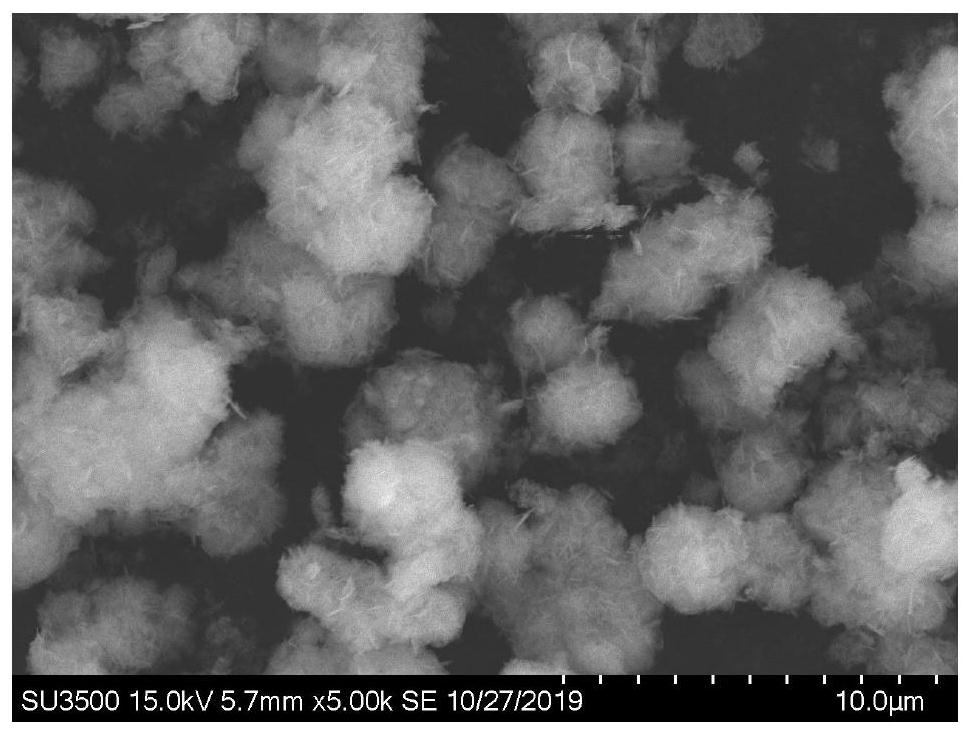

[0051] To the α-Co(OH) that embodiment 1 prepares 2 Solid carries out XRD and analysis, the result is as follows figure 1 as shown, figure 1 There are obvious diffraction peaks in , and each diffraction peak is related to α-Co(OH) 2 Consistent with standard cards, no β-Co(OH) 2 Miscellaneous peak; Prepare α-Co(OH) to embodiment 1, embodiment 2, embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com