Method for preparing 5-hydroxymethylfurfural by catalyzing glucose with tin-modified molecular sieve catalyst

A technology of hydroxymethylfurfural and molecular sieves, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the chemical concept of green and sustainable development, poor selectivity of 5-hydroxymethylfurfural, Hazardous living environment and other problems, to achieve good industrial application prospects, good catalyst stability, high catalytic activity and selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 1.0g of glucose, 1.0g of SAPO-34 catalyst, 2mL of water and 18mL of tetrahydrofuran into the autoclave, then replace the air in the autoclave with nitrogen and maintain the nitrogen pressure at 3Mpa, set the stirring speed to 700rpm, at 170°C After reacting for 2 hours at a certain reaction temperature, the reactor was cooled to room temperature to obtain a reaction solution containing the target product 5-hydroxymethylfurfural. The reaction solution was filtered and separated to remove the catalyst, and the filtrate was tested and analyzed by high-performance liquid chromatography, and the calculated 5- The yield of hydroxymethylfurfural was only 20.1%.

Embodiment 2

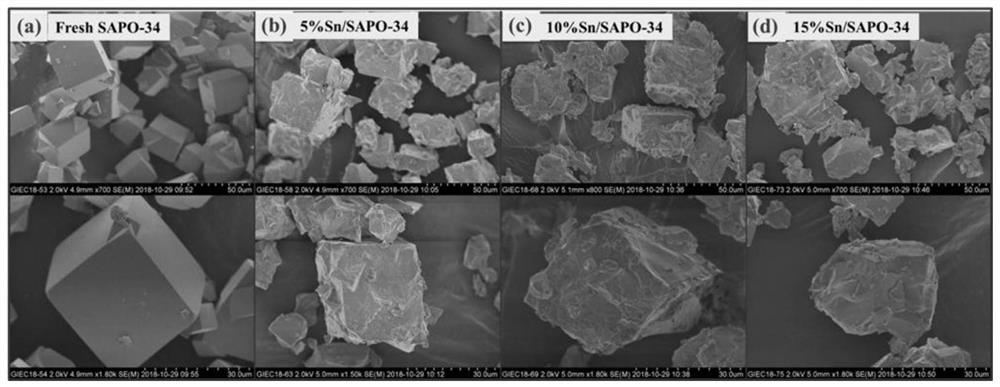

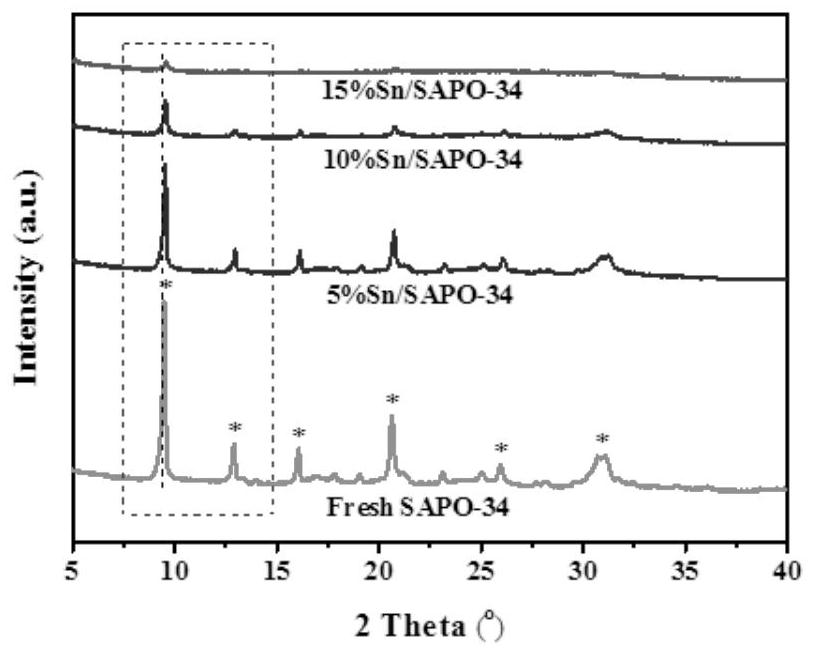

[0022] Weigh 0.005g SnCl 4 ·5H 2 O was dissolved in an appropriate amount of deionized water, and after it was completely dissolved, weighed 1.0g SAPO-34 molecular sieve and quickly added it to the above solution, stirred and impregnated at room temperature for 4 hours, and then dried in an oven at 120°C overnight to obtain white solid particles ; Grind the solid powder to a powder state to obtain a metal tin-modified molecular sieve catalyst, in which SnCl 4 ·5H 2 The mass ratio of O to SAPO-34 was 0.005:1, so the catalyst was labeled as 0.5% Sn / SAPO-34.

[0023] Take 1.0g of glucose, 1.0g of 0.5% Sn / SAPO-34 catalyst, 2mL of water and 18mL of tetrahydrofuran into the autoclave, then replace the air in the autoclave with nitrogen and maintain the nitrogen pressure at 3Mpa, set the stirring speed at 700rpm , after reacting for 2 hours at a reaction temperature of 170°C, cool the reactor to room temperature to obtain a reaction solution containing the target product 5-hydroxy...

Embodiment 3

[0025] Weigh 0.01g SnCl 4 ·5H 2 Dissolve O in an appropriate amount of deionized water, weigh 1.0g SAPO-34 molecular sieve after it is completely dissolved, and quickly add it to the above solution, stir and impregnate at room temperature for 4 hours, and then place it in an oven at 120°C to dry overnight to obtain a white solid Particles; the solid powder is ground to a powder to obtain a metal tin-modified molecular sieve catalyst, and the SnCl in the catalyst 4 ·5H 2 The mass ratio of O to SAPO-34 is 0.01:1, so this catalyst is labeled as 1%Sn / SAPO-34.

[0026] Take 1.0g of glucose, 1.0g of 1% Sn / SAPO-34 catalyst, 2mL of water and 18mL of tetrahydrofuran into the autoclave, then replace the air in the autoclave with nitrogen and maintain the nitrogen pressure at 3Mpa, set the stirring speed at 700rpm , after reacting for 2 hours at a reaction temperature of 170°C, cool the reactor to room temperature to obtain a reaction solution containing the target product 5-hydroxyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com