A latent self-curing resin coating composition and its construction method

A resin coating and self-curing technology, which is applied in epoxy resin coatings, coatings, devices for coating liquid on the surface, etc., can solve problems such as inconvenient use, and achieve the effect of both hardness and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

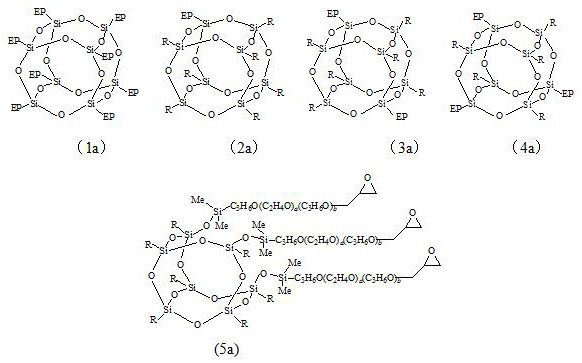

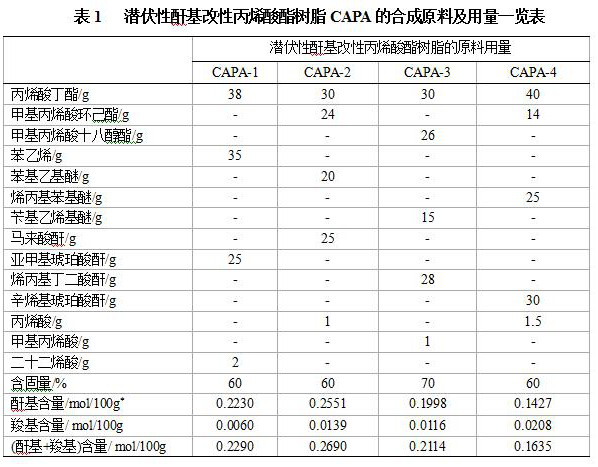

[0028] Take about 100g of epoxy resin E-51 (containing about 0.51mol of epoxy groups) with an epoxy equivalent of about 0.51 and a viscosity of about 11000mPa.s, and then weigh 3.0g (about 3%) according to the mass parts of E-51 The structure is as shown in the formula (1a): cage octa(2,3-glycidoxypropyl) POSS, 10.0g (about 10%) butyl glycidyl ether, 1.0g (about 1%) BYK-ATU dispersion Agent, 200.0g (about 200%) nano-silica sol (containing 60.0g of nanoparticles) with a solid content of 30% and an average particle diameter of about 20nm, after stirring and mixing, use a rotating speed of 1000r / min to stir and disperse for 30min with a dispersing disc, and then According to the molar ratio of the epoxy group contained in the system to the anhydride group + carboxyl group contained in the curing agent CAPA as 1:1, weigh 440.1g of carboxyl group with a solid content of 60% and an anhydride group content of about 0.223%. The content of butyl acrylate-co-styrene-co-methylene succini...

Embodiment 2

[0031] Take about 166.67g of epoxy resin E-20 solution with an epoxy equivalent of about 0.20 and a solid content of 60% (containing about 0.2mol of epoxy groups and 100g of solid resin, Baotashan Paint Co., Ltd.), press E-20 The solid mass parts are then weighed in turn 5.0g (about 5%), the structure is shown in the formula (1a) cage octa(3,4-epoxycyclohexylethyl) POSS, and the 20.0g structure is shown in the formula (2a) Cage mono(2,3-glycidoxypropyl) heptaisobutyl POSS, 20.0g (about 20%) C 12-14 Alkyl glycidyl ether AGE (Mw769.27), 0.5g (about 0.5%) of BYK-ATU dispersant, 50.0g (about 50%) of nano-silica sol with a solid content of 30% and an average particle size of about 20nm (Containing 15.0g of nanoparticles), after stirring and mixing, stir and disperse for 30min with a dispersing disc with a rotating speed of 1000r / min, and then compare the total amount of epoxy groups contained in the system with the (anhydride group + carboxyl group) contained in the curing agent CA...

Embodiment 3

[0034] Take about 100.0g of epoxy resin E-44 (containing about 0.44mol of epoxy groups) with an epoxy equivalent of about 0.44 and a viscosity of about 20000mPa.s, and weigh 10.0g (about 10 %), structure as shown in formula (4a), semi-closed cage tris(2,3-glycidoxypropyldimethylsilyl) heptaisobutyl POSS, 15.0g (about 15%) neopentyl di Alcohol diglycidyl ether reactive diluent, 0.8g (about 0.8%) BYK-ATU dispersant, 100.0g (about 100%) nano-silica sol with a solid content of 30% and an average particle size of about 20nm (containing nanoparticles 30.0g), after stirring and mixing, use a dispersing disc with a rotating speed of 1000r / min to stir and disperse for 30min, and then press the molar ratio of the total amount of epoxy groups contained in the system to the total amount of (anhydride groups + carboxyl groups) contained in the CAPA resin Then weigh 406.55g of butyl acrylate-co-cyclohexyl methacrylate-co-phenyl with a solid content of 70%, an anhydride group content of abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com