A kind of anhydride-based modified acrylate resin curing agent, preparation method and application

An acrylate and resin curing technology, used in epoxy resin coatings, coatings, etc., can solve problems such as inconvenience in use, and achieve the effects of expanding the scope of application, improving impact resistance, and improving mutual solubility and reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

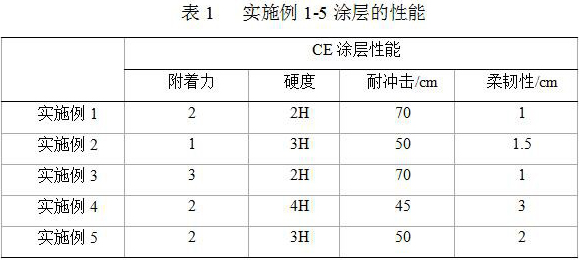

Examples

Embodiment 1

[0028] (1) Weigh 50.0g of butyl acrylate, 35.0g of styrene, 10.0g of 2-methylene succinic anhydride, 5.0g of docosanoic acid in order by mass parts, stir and mix to obtain a total of about 100g of monomer mixture ( A); then, take by weighing 0.5% by mass parts of A, the initiator AIBN of about 0.5g is mixed with A, and an ultrasonic cleaner with a power of 1KW carries out ultrasonic dispersion for 30min to obtain a total of about 100.5g transparent-slightly turbid liquid (B).

[0029] (2) Weigh 90.45g of about 90% by mass of B, then add 2% by mass of A, about 2.0g of molecular weight modifier thioglycolic acid, stir and mix well, record it as B1, and place it in the dropping funnel, spare.

[0030] (3) Add 42.85g of MB / BA solvent (MB:BA mass ratio = 1:1) and 10.05g of B, about 10% by mass, into a three-necked flask equipped with a thermometer, a stirrer and a dropping funnel, Stir to mix, pass N 2 Protect, stir and heat to 80°C to react for 10 minutes, then add B1 dropwise,...

Embodiment 2

[0032] (1) Weigh 30.0g lauryl methacrylate, 25.0g cyclohexyl acrylate, 14.5g benzyl vinyl ether, 30.0g allyl succinic anhydride, 0.5g acrylic acid in order by mass parts, stir and mix well, Obtain a total of 100g of monomer mixture (A); then, take 2% by weight of A, about 2.0g of initiator BPO and mix with A, and use an ultrasonic cleaner with a power of 1KW to carry out ultrasonic dispersion for 30min to obtain a total of About 102.0 g of clear liquid (B).

[0033] (2) Weigh 71.4g, about 70% by mass of B, then add 0.5% by mass of A, about 0.5g molecular weight modifier dodecanethiol, stir and mix well, record it as B1, and place it in the dropping funnel ,spare.

[0034] (3) Add 100g of DMB / EA solvent (DMB:EA mass ratio = 3:2) and 30.6g, about 30% by mass of B, into a three-necked flask equipped with a thermometer, a stirrer and a dropping funnel, Stir to mix, pass N 2 Protect, stir and heat to 70°C to react for 30 minutes, then add B1 dropwise, control the rate of B1 to d...

Embodiment 3

[0036] (1) Weigh 24.0g methyl acrylate, 30.0g butyl methacrylate, 20.0g stearyl methacrylate, 25.0g 2-octenyl succinic anhydride, 1.0g methacrylic acid in order by mass parts, stir and mix homogeneously, to obtain a total of 100g of monomer mixture (A); then, take 1% by weight of A, about 1.0g of initiator BPO and mix with A, and use an ultrasonic cleaner with a power of 1KW to carry out ultrasonic dispersion for 20min. A total of about 101.0 g of clear liquid (B) was obtained.

[0037] (2) Weigh 80.8g of about 80% by mass of B, then add 1% by mass of A, about 1.0g of molecular weight regulator thioglycolic acid, stir and mix well, record it as B1, put it in the dropping funnel, spare.

[0038] (3) Add 66.67g of BA and 20.2g of about 20% by weight of B in turn into a three-necked bottle equipped with a thermometer, a stirrer and a dropping funnel, stir and mix well, and pass through N 2 Protect, stir and heat to 80°C to react for 15min first, then add B1 dropwise, control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com