A kind of anticorrosion type polyurethane water-based coating and preparation method thereof

A water-based coating and polyurethane technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as high surface tension of water, cross-linking of difficult-to-film-forming substances to form a film layer, and corrosion resistance of the film layer. , to achieve the effect of smooth surface, good self-cleaning property and long aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

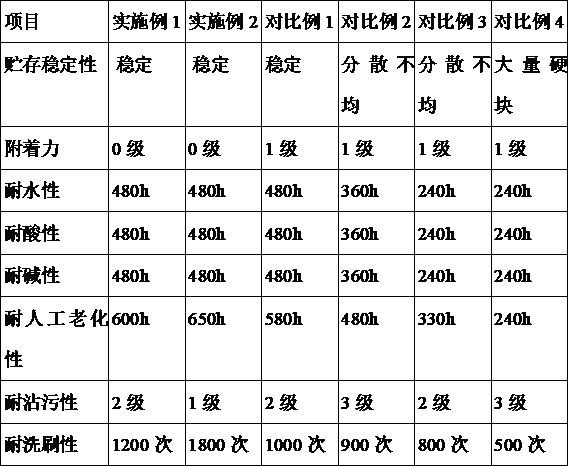

Examples

Embodiment 1

[0025] S1: Add 30 g of polyether triol (Mn=3000 g / mol) into the reaction flask, stir in vacuum for 2 h, then add 7.5 g of diphenylmethane diisocyanate and 50 ppm of dibutyltin dilaurate (catalyst), Stirring reaction 1 h, obtain polyurethane prepolymer;

[0026] S2: Put 1 g of carboxylated graphene in 100 ml of thionyl chloride and 20 ml of N, N-dimethylformamide solvent, ultrasonically disperse it evenly, and then reflux at 70-80 °C for 2 h; After the reaction is completed, add 10 g of double-terminated amino polyethylene glycol (Mn=3000 g / mol), and continue to stir and reflux for 24 h. After the reaction is completed, filter, wash, and dry to obtain amino-terminated polyether-grafted graphene;

[0027] S3: Add 1 g of the amino-terminated polyether-grafted graphene into 100 ml of tetrahydrofuran, ultrasonically disperse for 4 hours, and add 0.2 ml of triethylamine and 10 g of KH560 (silane coupling agent) under a nitrogen atmosphere, and then Reflux at 50-60 °C for 24 h, then...

Embodiment 2

[0032] S1-S4 is the same as embodiment 1,

[0033] S5 is specifically: transfer 60 parts of polyurethane emulsion into the stirring device, set the stirring speed to 900 r / min, add 2 parts of defoamer and 10 parts of leveling agent in turn, and stir for 20 min; then set the stirring speed to 1100 r / min / min, add 3 parts of film-forming aids and 15 parts of fillers and stir for 20 minutes; finally add 0.8 parts of defoamer, 1 part of leveling agent and 20 parts of water, and stir at 1200r / min for 15 minutes to obtain anti-corrosion polyurethane water-based paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com