Steel sheet passivation process, passivated steel sheet and vapor chamber

A technology of vapor chamber and steel sheet, which is applied in the coating process of metal materials, lighting and heating equipment, indirect heat exchangers, etc., and can solve problems such as difficult ultra-thinning, non-condensable gas generation, and reduced service life of steel , to achieve the effect of strong corrosion resistance, good bonding force and dense passivation film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

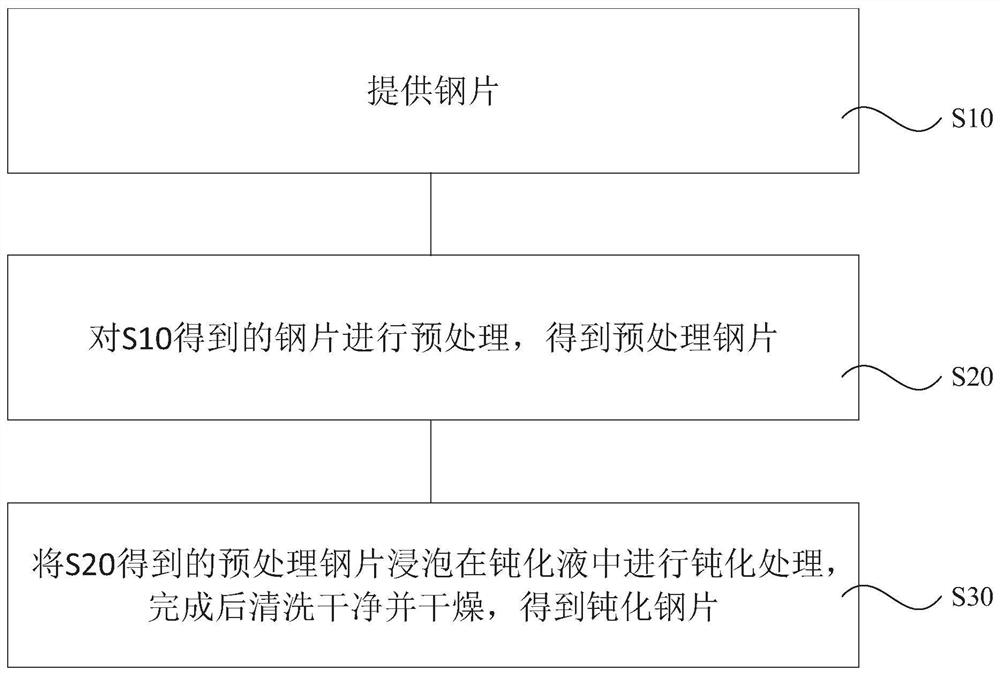

[0089] S10. Obtain a stainless steel cover plate by etching a stainless steel sheet with a thickness of 0.05-0.4 mm.

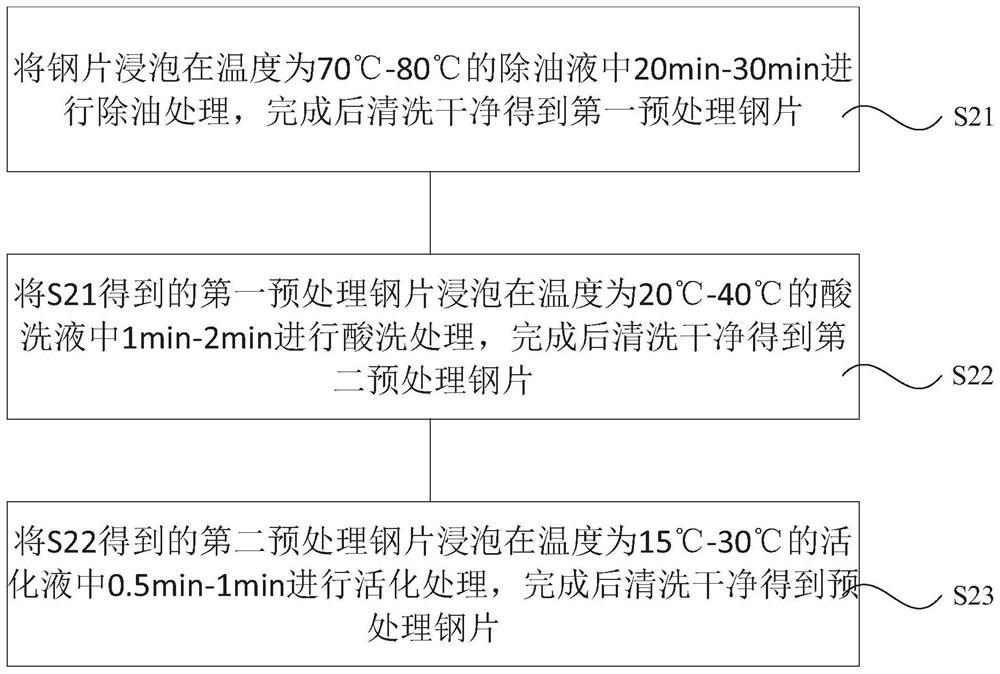

[0090] S20, sequentially performing degreasing treatment, pickling treatment and activation treatment on the stainless steel cover plate.

[0091] Degreasing: Soak the stainless steel cover in 80°C degreasing solution for 30 minutes, and then immediately clean it with pure water. The components of the degreasing solution are 20g / L sodium hydroxide, 20g / L sodium carbonate and 4mL / OP emulsifier of L;

[0092] Pickling: Soak the degreased stainless steel cover in the pickling solution for 1 min at room temperature, and then immediately clean it with pure water. The components of the pickling solution are 20% hydrochloric acid and 3g / L if Ding;

[0093] Activation: Soak the pickled stainless steel cover plate in the activation solution at room temperature for 30s, take it out, rinse it quickly, and immediately put it into the tank for the next step. The activat...

Embodiment 2

[0096] In embodiment 2, S10 and S20 are consistent with embodiment 1.

[0097] S30. Passivation treatment: soak the activated stainless steel cover plate in a passivation solution at 70°C for 30 minutes, wash it with pure water, and dry it in an oven at 80°C for 20 minutes to form a passivation film on the surface of the stainless steel cover plate , to obtain a passivated stainless steel cover plate, the composition of the passivation solution is 7g / L of benzotriazole, 0.5g / L of cerium nitrate, 5g / L of sulfosalicylic acid and 2g / L of polyvinyl alcohol, The pH of the passivation solution is 6.

Embodiment 3

[0099] In embodiment 3, S10 and S20 are consistent with embodiment 1.

[0100] S30. Passivation treatment: soak the activated stainless steel cover plate in a passivation solution at 45°C for 10 minutes, wash it with pure water, and dry it in an oven at 80°C for 15 minutes to form a passivation film on the surface of the stainless steel cover plate , to obtain a passivated stainless steel cover plate, the composition of the passivation solution is 10g / L of benzotriazole, 3g / L of zinc sulfate, 8g / L of sulfosalicylic acid and 1g / L of polyvinyl alcohol, passivation The pH of the solution is 4.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com