Surface modification method of PBO fibers

A surface modification and fiber technology, applied in the field of surface modification of PBO fibers, can solve problems such as poor adhesion, and achieve the effects of poor adhesion, roughness and specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

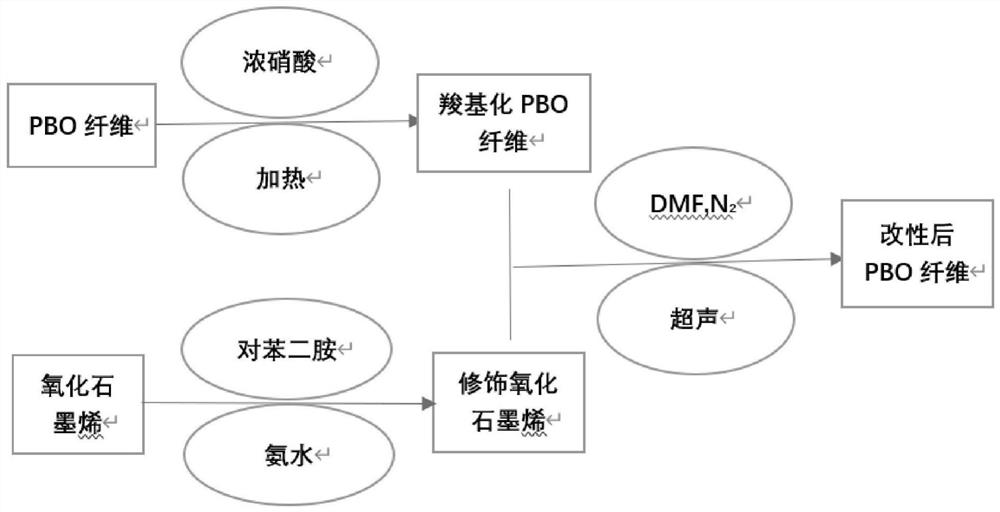

Method used

Image

Examples

Embodiment 1

[0024] A kind of surface modification method of PBO fiber, concrete steps are as follows:

[0025] (1) Preparation and modification of graphene oxide:

[0026] Adopt traditional Hummers method to prepare graphite oxide, in 100mL deionized water 10mg graphite oxide, ultrasonic stirring dissolves, then add appropriate amount of ammonia water, adjust the pH value of reaction system to be 9, add 0.8g p-phenylenediamine in reaction system, keep The temperature was 90° C., and the reaction system was reacted for 6 hours under the condition of mechanical stirring. After complete reaction, the product is vacuum filtered and dried to obtain modified graphene oxide;

[0027] (2) Carboxylation treatment of PBO fiber:

[0028] In a three-necked flask filled with 150ml of concentrated nitric acid, add 7g of PBO fiber, stir the reaction at 150r / min at 75°C for 1.5h, cool to room temperature, take out the PBO fiber, wash it with deionized water until neutral, vacuum Dry at 80°C for 5 hour...

Embodiment 2

[0033] A kind of surface modification method of PBO fiber, concrete steps are as follows:

[0034] (1) Preparation and modification of graphene oxide:

[0035] Adopt traditional Hummers method to prepare graphite oxide, in 100mL deionized water 10mg graphite oxide, ultrasonic stirring dissolves, then add appropriate amount of ammonia water, adjust the pH value of reaction system to be 10, add 0.5g p-phenylenediamine in reaction system, keep The temperature was 100° C., and the reaction system was reacted for 4 hours under the condition of mechanical stirring. After complete reaction, the product is vacuum filtered and dried to obtain modified graphene oxide;

[0036] (2) Carboxylation treatment of PBO fiber:

[0037] Add 6g of PBO fiber to a three-necked flask filled with 100ml of concentrated nitric acid, stir and react at 100r / min for 2h at 70°C, cool to room temperature, take out the PBO fiber, wash it with deionized water until neutral, vacuum 80 ℃ drying for 5 hours to...

Embodiment 3

[0042] A kind of surface modification method of PBO fiber, concrete steps are as follows:

[0043] (1) Preparation and modification of graphene oxide:

[0044] Graphite oxide was prepared by the traditional Hummers method, 10mg of graphite oxide in 100mL deionized water was dissolved by ultrasonic stirring, and then an appropriate amount of ammonia water was added to adjust the reaction volume.

[0045] The pH value of the system was 11, 0.2 g of p-phenylenediamine was added to the reaction system, the temperature was kept at 80° C., and the reaction system was reacted for 9 hours under the condition of mechanical stirring. After complete reaction, the product is vacuum filtered and dried to obtain modified graphene oxide;

[0046] (2) Carboxylation treatment of PBO fiber:

[0047] In a three-necked flask filled with 200ml of concentrated nitric acid, add 8g of PBO fiber, stir the reaction at 200r / min at 80°C for 2.5h, cool to room temperature, take out the PBO fiber, wash i...

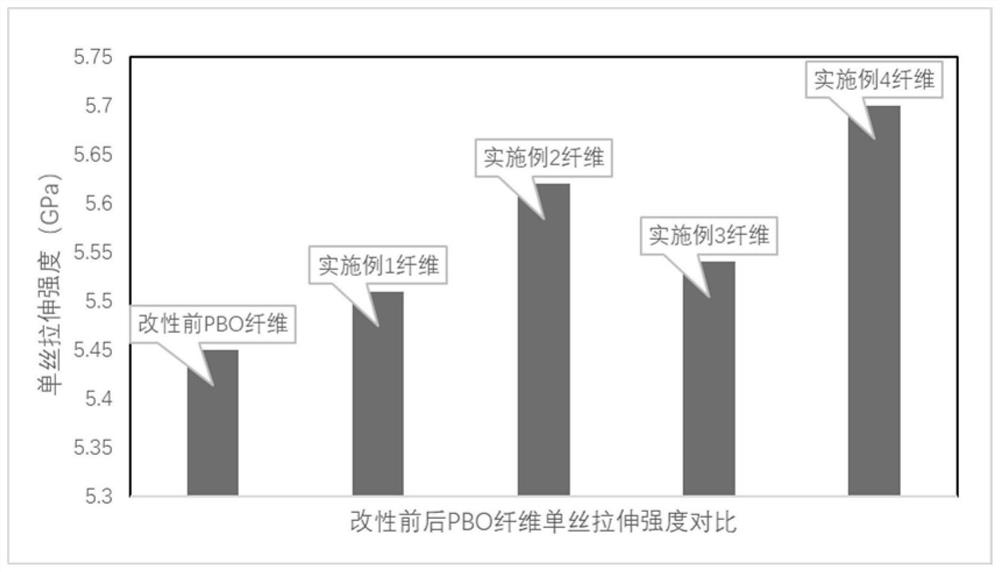

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com